GOOD CONNECTIONS

Page 70

Page 71

If you've noticed an error in this article please click here to report it so we can fix it.

British Telecom relies on a 78,000-strong vehicle fleet for making good connections. Commercial Motor talks to the man behind the Maestros.

put Maureen Lipman in a yellow British Telecom van and you've brought together the two things which most people would instantly associate with BT.

The man in charge of BT's 43,000 vans, not to mention 35,000 cabs, trailers, cars and specialist vehicles, is Peter Mitchell. "Maintaining and servicing the yellow fleet is our major role in life," says Mitchell. However, he is responsible not only for the smooth running of the fleet, but also for spending an annual £80 million on new vehicles to keep BT on the move across the country. "We are the supplier and the maintainer."

Since 1984, BT has run its transport operation from a central division, the Motor Transport Executive (MTE), based in east Birmingham. "We did this in order to pull together all the motor transport parts of British Telecom into one organisation to control costs. Before that, each area ran its own motor transport unit," explains Mitchell.

The MTE operates as a contract hire company within BT, charging vehicles out at a commercial contract hire rate. 'We negotiate a customer supply agreement, trying to ensure we are offering the best service at the most competitive price to our customer."

Its substantial vehicle purchasing budget puts BT in the big fleet first division and gives it considerable clout with manufacturers. Mitchell has moved BT policy away from putting a supply contract out to tender every year, favouring long-term agreements with a manufacturer. "It's better for us and it's better for them," he states. "If you're reviewing a contract every year, it can result in a lot of chopping and changing and basically ends up with you chasing price. But price is not the only criteria — it's the whole life cost we're anxious to reduce. This way we can establish cost over quite a number of years."

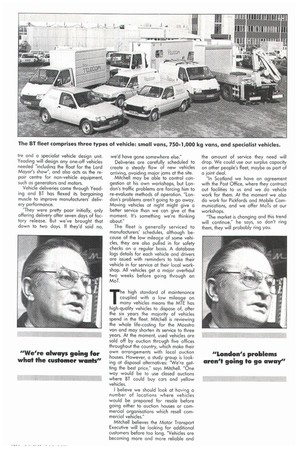

The fleet divides into three broad subcategories: small vans, mainly used for installers and customer repair services; 750kg to 1,000kg payload vans for jointers and installers; and specialist vehicles, which includes HGVs. "The sheer volume we buy — between 10,000 and 14,000 vehicles a year — means we buy direct from the manufacturer," says Mitchell. 'We look at all the options, go to tender and test vehicles usually for about six months."

The Austin Maestro petrol-powered van, of which BT runs about 25,000, is now a proven part of the fleet. 'We signed the Maestro agreement two years ago and we've found it's a vehicle the right size at a reasonable cost that meets our requirements. We continually review performance against the manufacturer's criteria. Before the Maestro we used the Morris Ital. We also looked at the Vauxhall and Ford range but the Maestro won. We do use the Ford diesel van as it's more economical for highmileage vehicles; our vehicles on average only do 9,000 miles a year."

Ford came up trumps with the Transit for BT's mid-range vehicles. "The Transit's servicing schedule, modern engine and electronics costed in very well and it's proving to be exceptionally good and versatile," enthuses Mitchell. "It's very reliable, its running costs are low and it scores high on driver acceptability. Before the Transit we used the

Leyland Daf Freight Rover, but the drivers like the Transit's modern cab design. It's functional — the operator can stand up in the van to work, and the cab can be used with another body."

With more than 400 fitting designs across the fleet, Mitchell uses a variety of arrangements to fit the new vehicles. "Manufacturers probably do about 60% and we do 40%," he says. "Often the manufacturer will fit the basics, like the racking and the bulkhead, and our workshops will do the rest. In general, our fleet are mobile tool boxes. The customer will tell us if they want ladder racks or beacons, for example, and we'll fit those. Obviously it varies from type to type; Austin is doing all the Maestros for us at the moment." BT's specialist vehicles include anything from rodding and lighting cabling units, which lay underground cable, to pole erection units and platform elevators. The vehicle design division puts together a design for a vehicle and issues the MTE with a schedule of requirements. Mitchell selects a manufacturer and trials the prototype for at least six months as well as choosing suppliers for any auxiliary equipment required, such as pumps and generators and rodding machines. BT runs 1,600 trailers and 900 tractive units, the majority of which are Iveco Ford. Mitchell keeps up with what is coming out on the market, though: 'We're always going for what the customer wants."

Out of a total Motor Transport Executive workforce of 2,900, mechanics (known as technicians in BT) represent 2,500, working out of 300 workshops all over the UK. Each workshop is allocated part of the fleet, though some will be responsible for as few as 30 vehicles, while the largest site, at Yeading near London, looks after 1,500. There are 30 workshops scattered around the capital, servicing 18,000 vehicles. All workshops work to varying schedules as demanded by their local BT force.

yeading employs 200 and Mitchell refers to it with pride as his bestequipped, most up-to-date workshop, housing stores, a major repair cen

tre and a specialist vehicle design unit. Yeading will design any one-off vehicles needed "including the float for the Lord Mayor's show", and also acts as the repair centre for non-vehicle equipment, such as generators and motors.

Vehicle deliveries come through Yeading and BT has flexed its bargaining muscle to improve manufacturers' delivery performance.

"They were pretty poor initially, only offering delivery after seven days of factory release. But we've brought that down to two days. If they'd said no, we'd have gone somewhere else." Deliveries are carefully scheduled to create a steady flow of new vehicles arriving, avoiding major jams at the site. Mitchell may be able to control ccingestion at his own workshops, but London's traffic problems are forcing him to re-evaluate methods of operation. "London's problems aren't going to go away. Moving vehicles at night might give a better service than we can give at the moment. It's something we're thinking about."

The fleet is generally serviced to manufacturers' schedules, although because of the low milease of some vehicles, they are also pulled in for safely checks on a regular basis. A database logs details for each vehicle and drivers are issued with reminders to take their vehicle in for service at their local workshop. All vehicles get a major overhaul two weeks before going through an MoT.

The high standard of maintenance coupled with a low mileage on many vehicles means the MTE has high-quality vehicles to dispose of, after the six years the majority of vehicles spend in the fleet. Mitchell is reviewing the whole life-costing for the Maestro van and may shorten its service to three years. At the moment, used vehicles are sold off by auction thrcugh five offices throughout the country, which make their own arrangements with local auction houses. However, a study group is looking at disposal alternatives: "We're getting the best price," says Mitchell. "One way would be to use closed auctions where BT could buy cars and yellow vehicles.

I believe we should look at having a number of locations where vehicles would be prepared for resale before going either to auction houses or commercial organisations which resell commercial vehicles."

Mitchell believes the Motor Transport Executive will be looking for additional customers before too long. "Vehicles are becoming more and more reliable and the amount of service they need will drop. We could use our surplus capacity on other people's fleet, maybe as part of a joint deal.

"In Scotland we have an agreement with the Post Office, where they contract out facilities to us and we do vehicle work for them. At the moment we also do work for Pickfords and Mobile Communications, and we offer MoTs at our workshops.

"The market is changing and this trend will continue," he says, so don't ring them, they will probably ring you.