TIPPING GEAR IN ITS MANY FORMS.

Page 117

Page 118

If you've noticed an error in this article please click here to report it so we can fix it.

Built to Cope with Loads of from 1 Ton to 12 Tons, These Gears Should Meet All Requirements.

MUCH of the efficiency of road transport depends not upon the actual speed of transit, but upon the reduction iii terminal delays, and any means by which such delays can be reduced should always receive the most careful consideration. In this connection the employment of tipping and loading devices provides an excellent field for investigation, but caution must be exercised, for many means for loading and unloading, which have been designed in the past have not proved altogether satisfactory and have enjoyed but a brief life. We can give one instance of this in the roller-blind type of body floor, which appeared at one time to possess great

• potentialities, but of which we have heard very little in recent years. Similarly, barrel-loading and unloading mechanism, which would appear to be of considerable service to brewers and others, does not seem to have attained anything iu the nature of a vogue. From the point of view of unloading, the tipping gear in its many forms appears still to be the most satisfactory of all, and in this article we will, practically, confine ourselves to it.

The power for such gears can be obtained from five sources :—(1) The driver or unloader ; (2) the engine ; (3) the force of gravity ; (4) a combination of manual effort and gravity ; (5) tho battery in the case of an electric vehicle.

Dealing with these in the order mentioned, hand-operated gears can be considered as being quite suitable for vehicles carrying moderate loads, and even for heavier vehicles where the tipping gear is not likely to be used to any great extent. The majority of this typo consists of a single screw, or two screws situated between the cab and the tipping body. In one or two cases, however, and particularly where side as well as end tipping is desired, a screw mounted on gimbals is positioned under the chassis. In another pattern, instead of there being one or more vertical screws, a cross-screw is employed. This has right and left-hand threads, which draw together the ends of two levers fulcrumed at their top to a single bracket attached to the body. Certain of the side tippers also have • cross-screws, the threads in such eases, however, all being in the same direction. It will be realized that in order to obtain a high angle of tip plain screws would often be of excessive length, so that what is termed a telescopic screw is often em ployed. This consists of one screw working inside another, so that when the outer screw has reached the limit of its travel the inner one almost doubles the effective lift.

Engine-operated gears are often little more than modifications of the manual type, but there is an increasing demand for those employing one or more hydraulic cylinders and rams, the engine then driving a small pump through a power take-off from the gearbox or in any other convenient manner. Such a gear does not necessitate the employ ment of a reducing gear embodying, in some cases, Quite a number of pinions, and can be added to existing chassis without the need for any great modifications. The cylinder or cylinders can be disposed vertically or horizontally according to the type of gear, and when well made there is little or no loss of oil andvery little risk of damage through dirt or mud.

In some hydraulic gears the rams act practically directly upon the body. In others, as in the Daimler Horizontal. Hydraulic and the Wood underbody Hydraulic Hoist, cam gear is interposed, whilst in one or two foreign designs the ram actuates lifting arms through the medium of rack and pinion gear. When dealing with engine-operated gears, we 'must not forget those employed on steam wagons. Certain of these are driven through the medium of pinions, whilst

others employ hydraulic rams. deriving their power from the feed-water pump.

Gravity tippers, if well designed, often prove quite satisfactory. They are usually provided with tipping hoppers, normally held upright, but which, when released, fall to the side or rear and return immediately the load has been released. Such mechanism is useful for vehicles employed by builders and others, and it can also well be applied to trailers, but in the case of ordinary bodies it is usually necessary to employ

a combination of gravity and hand operation, and to effect this the body is run back or to the side by means of one or more screws until it reaches a point at which gravity can overbalance it. Here, again, the body usually returns to the horizontal of its own accord, ready for screwing back into position.

• With the electric vehicle the problem is usually very simple. It is a general practice to employ a separate small electric motor used only for tipping purposes. Of course, if much' tipping is to be done the drain upon the battery must necessarily reduce its mileage capacity to a considerable extent, but for shortjourney work this may not be of supreme importance. Where it is so, however, the tipping gear must derive its power from some other source, and, in actual practice, the body is usually arranged to operate on the method described in the previous paragraph, being caused to run back and tip over.

There are a great many manufacturers of tipping gears in our first . category, i.e., those worked by hand.

J. Brockhou,se and Co.' Ltd., Victoria Works, West Bromwich, makes single and twin-screw tipping gears for all types of commercial vehicle, with lifting capacities ranging from 20 cwt. -to 6

tons. It also markets light tipping gears for Ford vehicles and special telescopic gears for the same make.

Amongst its many other activities, W. R Cary, Ltd., Red Bank, Manchester, includes the production of telescopic tipping gears, both of the singlescrew and twin-screw type. The benefit of these screws is that they can give a high lift without being of unwieldy length. An advantage of all the models is that the gears are well protected, whilst lubricators are fitted to the bearings. Single-screw side-tipping gears are also made, and these can deal with loads

ranging from 1 ton to 5 tons, For either-side tipping there is a somewhat novel type in which the two screws are driven through the medium of a layshaft having two universal joints. The primary shaft is manually operated and a pinion takes the drive from this to another pinion on the'layshaft.

Gears for end-tipping trailers, etc., are manufactured by R. A. Dyson and Co., Ltd., 76-80, Grafton Street, Liverpool, IS., in various sizes to deal with loads from 1 ton up to 8 tons. The designs include single and double telescopic screws, all of which are equipped with self-aligning devices. The same remarks apply to the company's side-tipping gear. All the important wearing parts, particularly as regards the end-tipping gear, are dustproof, whilst they are so simple that there is practically nothing

to get out of order. All gears are equipped with enclosed heavy-type ballthrust bearings for supporting the screw. Each has a safety ratchet and les complete with channel, etc., ready for fixing to the chassis. In the either-side tipping type two screws are employed. The nut on each of these is connected by levers to the middle of the body.

Few makers have had more experience in the development of hand-operated tip ping gears than the Eagle Engineering Co.; Ltd., Eagle Works, Warwick. Simple single screws are made for the fighter types of vehicle, such as the Ford, and single telescopic screws for the heavier models. The gearing is all enclosed and loads up to 5 tons can be handled. An advantage of the differential telescopic screws is that more rapid tipping can be effected, for _After the body has been tipped half-way the amount of energy required to complete the operations is considerably reduced and the internal screw is threaded to give a more rapid action. Ball thrust collars; gunmetal bushes and gunmetal tipping nuts are provided.

The Milshaw patent universal gear is manufactured by A. R. Edwards and Co., 1, Drewton Street, Bradford. This is a most efficient type for dealing with the heavier loads. The important points are that the screw is allowed to float in a lateral position so that any distortion of the chassis frame does not cause friction. The screw is supported by heavy ball-thrust hearings, and there are universal joints on the winding cross-shaft which ensure the gear wheels always remaining in correct mesh. The load capacities range from 20 cwt. to 6 tons in the special gear, some of which have simple and others telescopic screws.

Ellis Bros. (Halifax), Ltd., Halifax, manufactures gears in capacities of 1 ton to 6 tons, these being of the end. tipping type. They have single, simple or telescopic screws, according to size, and ball-thrust races. The company also manufactures a patent universal. tipping gear in capacities of from 20 cwt. to 50 cwt. This enables the load to be tipped in any position in an arc of 200 degrees.

Gears for dealing with loads of from 1 ton to 6 tons with single and double screws are manufactured by Albert Jagger, Green Lane, Walsall. These gears are sent out complete, fitted in channel-iron members ready to bolt to the chassis, and a hinge bar with brackets is provided for the rear of the body. Three-way tippers are also built, and a special light-type single-screw gear for Fords and similar vehicles, including the hinge bar, weighs only 1 cwt.

Apart from being specialists in the manufacture of springs and the respringing of private cars for conversion to commercial work, John Perks and Son, Crown Works, Lye, Stourbridge, supply plain and telescopic tipping gears for all loads up to 6 tens.

An interesting type of gear is the Quikko, marketed by J. W. Pickavant and Co., Ltd., Quikko Works, Lombard Street, Birmingham. This has a crossscrew, left-hand threaded to one side and right-hand threaded to the other. Each thread carries a nut and a set of levers fulcrumed to the centre of the body, and when the screws arc drawn together the body is lifted. This gear is the Jennings patent, and the 1-ton model for Fords weighs complete, except for the handle, 571 lb.

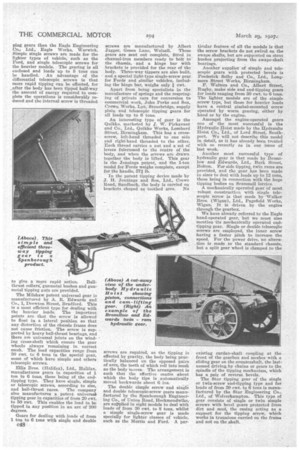

In the patent tipping device made by J. H. Jennings and Son, Ltd., Crewe Road, Sandbach, the body is carried on brackets shaped as toothed arcs. No screws are required, as the tipping is effected by gravity, the body being practically balanced on the opposed pairs of arcs, the teeth of which roll into mesh as the body moves. The arrangement is such that the effective centre about which the body tips is automatically moved backwards about 6 ins.

The double simple screw and single and double telescopic-screw gears manufactured by the Spenborough Engineering Co., of Union Road, Reckmondwike, are suPplied in eight models to deal with loads of from 30 cwt. to 8 tons, whilst a simple single-screw gear is made specially for lighter classes of vehicle, such as the Morris and Ford. A par

fielder feature of all the models is that the screw brackets do not swivel on the swaps shafts, but are supported on stout bushes projecting from the swape-shaft bearings.

Another supplier of simple and telescopic gears with protected bevels is Frederick Selby and Co., Ltd., Longmore Street Works, Birmingham.

F. Walters and Co., Albert Street, Rugby, make side and end-tipping gears for loads ranging from 30 cwt. to 6 tons. The lighter models are of the simple screw type, but those for heavier loads have a central gimbal-mounted screw operated by worm gearing, either by hand or by the engine.

Amongst the engine-operated gears one of the most successful is the Hydraulic Hoist made by the Hydraulic Hoist Co., "Ltd., of Lord Street, South-. port. We will not describe this model in detail, as it has already been treated with so recently as in our issue of last week.

Another most successful type of hydraulic gear is that made by Bromilow and Edwards, Ltd., Bark Street, Bolton. For side tipping, twin rams are provided, and the gear has been made in sizes to deal with loads up to 12 tons, these being in connection with the huge tipping bodies on Scammell lorries.

A mechanically operated gear of most robust construction with single telescopic screw is that made by Walker Bros. (Wigan), Ltd., Pasefleld Works, Wigan. It is driven by the engine through the gearbox.

We have already referred to the Eagle hand-operated gear, but we must also mention its mechanically operated endtipping gear. Single or double telescoac screws are employed, the inner screw laving a faster pitch to increase the speed. For the power drive, no alteration is made to the standard chassis, but a split gear wheel is clamped to the existing cardan-shaft coupling at the . front of the gearbox and meshes with a sliding gear on the countershaft, the lastnamed driving by chains or gears to the spindle of the tipping mechanism, which has a pair of reverse bevels.

The Star tipping gear of the single or twin-screw end-tipping type and for loads of from 30 cwt. to 6 tons is manufactured by the Star Engineering Co.. Ltd., of Wolverhampton. This type of gear consists of single or twin simple Screws with bevel gears protected from dirt and mud, the casing acting as a support for the tipping screw, which works in trunnions carried on the frame and not on the shaft.