Restoring Worn Parts.

Page 100

If you've noticed an error in this article please click here to report it so we can fix it.

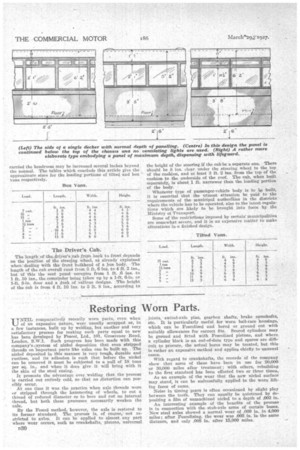

TTNTIL comparatively recently worn parts, even when

of an expensive nature, were usually scrapped or, in a few instances, built up by welding, but another and very satisfactory process for makine' such parts equal to new has been developed by Fescol,Ltd., 101, Grosvenor Road, London, SAVA. Such progress has been made with this company'sd system of nickel deposition that even stripped threads on 'important parts like axles can be built up. The nickel deposited in this manner is very tough, durable and rustless, and its adhesion is such that before the nickel can be removed it must be subjected to a pull of 18 tons per sq. in., and when it does give it will bring with it the skin of the steel casing.

It presents the advantage over welding that the process is carried out entirely cold, so that no distortion can possibly occur.

At one time it was the practice when axle threads wore or stripped through the hammering of wheels, to cut a thread of reduced diameter or to bore and cut an internal thread, but both these processes necessarily weaken the axle.

By the Fescol method, however, the axle is restored to its former standard. The process is, of course,' not restricted to axles. It can be applied to almost any part where wear occurs, such as crankshafts, pistons, universal joints, swivel-axle pins, gearbox shafts, brake camshafts, etc. It is particularly useful for worn ball-race housings, which can be Fcscolized and bored or ground out with suitable allowances for correct fits. Scored cylinders may be ground and fitted with Fescolized pistons, and vvhere a cylinder block is an out-of-date type and spares are difficult to procure, the actual bores may be treated, but this is rather an expensive method and applies chiefly to unusual Cases.

With regard to crankshafts, the records of the company show that some of these have been in use for 20,000 or 30,000 miles after treatment ; with others, rebuilding to the first standard has been effected two or three times, As an example of the wear that the new nickel surface may stand, it can be suCcessfully applied to the worn lifting faces of cams.

Noise in timing gears is often occasioned by slight Play between the teeth. They can usually be quietened by depositing a film of unmachined nickel to a depth of .002 in.

An interesting example of the benefits of the process is in connection with the stub-axle arms of certain buses. New steel axles showed a normal wear of .009 in. in 4,000 miles ; after Fescolizing, the wear was .003 in. in the same distance, and only .008 in. after 15,000 miles.