ATTRACTIONS OF

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

TANKCON

Bryan Jarvis reports an increasing use of stainless steel by tanker manufacturers exhibiting at the RHA's Bristol show

THE NEW Bristol Exhibition Centre provided an admirable setting for what was effectively the first independent exhibition and convention, organised by the Road Haulage Association's tanker functional group, for the road tanker industry.

Although two of the three days of TankCon were marred by intermittent rain showers, the event proved to be the attraction that it promised, with representations from all but a few of the industry's prominent manufacturers.

More than 50 new and refurb ished quality tankers provided an insight into the wide range of commodities carried on Britain's roads.

Tanks for highly viscous liquids, such as molasses, were parked alongside ones for hauling flammable and corrosive materials. Milk, waste products and powder carriers were also on show.

While a great deal of the componentry was made from aluminium in order to save weight and thus gain payload, an increasing use of stainless steel was also evident.

Examples of most of the different designs of available triaxle suspensions were on show whether pneumatic, fluid or mechanical. Very few manufacturers omitted to include a lifting axle.

lithe finished quality of new tankers was high, so, too, was that of the refurbished units, several of which were to be seen on the Bristol quayside.

Perhaps the most improbable exhibitor of all was the London Borough of Thurrock which used the occasion to help promote thc industrial attractions, of this area by the Thames.

With a new link road to the nearly completed M25, the borough's container port facilities at Tilbury and three major airports less than an hour away, it is hardly surprising that many large companies are looking closely at Thurrock.

What are the trends?

One of the topics at the Tanker Convention was how a large British chemical company and hauliers co-exist.

After 16 years with British Petroleum Chemicals, Vin Bessant is well qualified to speak on its steadily rising fortunes. Of the 110 million tons of chemicals produced in Britain almost half of it, mostly liquids, is moved around the country by road tanker.

Despite the vagaries of the chemical industry, road bulk movements will grow by around one to three per cent and will remain so for a while yet, he said. With a choice between contract hire, spot hire or contract haulage, BP prefers to buy in transport but in a way that is of mutual benefit.

For its part, he said, BP has an approved list of hauliers but lays even greater importance on the driver who is a representative of the chemical industry and also of the haulage company. Speaking for the chemical industry, Mr Bessant stressed the need for haz-freight training, retraining within five years and the maintaining of driver records.

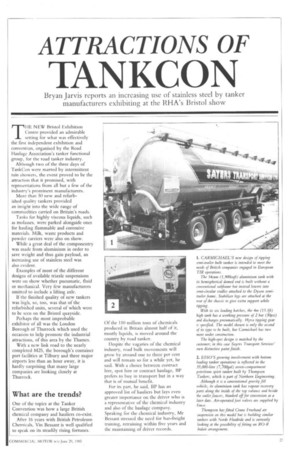

1. CARMICHAEL'S new design of upping semi-trailer bulk tanker is intended to meet the needs of British companies engaged in European TIR operations.

The 54cum (1,900ccift) aluminium tank with its hemispherical domed end is built without a conventional subframe but instead lowers into semi-circular cradles attached to the Dyson semitrailer frame. Stabiliser legs are attached at the rear of the chassis to give extra support while tipping.

With its six loading hatches, the 4in (13.Ift) high tank has a working pressure of 2 bar (30psi) and discharges pneumatically. Hyva tipping gear is specified. The model shown is only the second of its type to be built, but Carmichael has two more under construction.

The high-spec design is matched by the customer; in this case Sayers Transport Services' own distinctive paint finish.

2. ESSO'S growing involvement with bottom loading tanker operations is reflected in the 35,000-litre (7,700gal) seven-compartment petroleum spirit tanker built by Thompson Tankers, which is pan of Northern Engineering.

Although it is a conventional gravity fill vehicle, its aluminium tank has vapour recovery parts along the inside of the top valance and beside the outlet faucets, blanked offfor conversion at a later date. Air-operated loot valves are supplied by Emco_ Thompson has fitted Crane Fruehauf air suspension on this model but is building similar tankers with Norde Fluidride and is currently looking at the possibility of fitting an RO-R Indair arrangement.