Successful Results from

Page 84

Page 85

If you've noticed an error in this article please click here to report it so we can fix it.

Pneumatic Tyres on Tractors

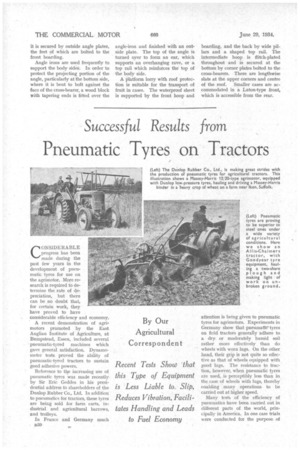

CONS1DERABLE progress has been made during the past few years in the development of pneumatic tyres for use on the agrimotor. More research is required to determine the rate of depreciation, but there can be no doubt that, for certain work, they have proved to have considerable efficiency and economy.

A recent demonstration of agrimotors promoted by the East Anglian Institute of Agriculture, at Bumpstead, Essex, included several pneumatic-tyred machines which gave general satisfaction. Dynamometer tests proved the ability of pneumatic-tyrod tractors to sustain good adhesive powers.

Reference to the increasing use of pneumatic tyres was made recently by Sir Eric Geddes in his presidential address to shareholders of the Dunlop Rubber Co., Ltd. In addition to pneumatics for tractors, these tyres are being sold for farm carts, industrial and agricultural barrows, and trolleys.

In France and Germany much D.30 attention is being given to pneumatic tyres for agrimotors. Experiments in Germany show that pneumatic" tyres on field tractors generally adhere to a dry or moderately humid soil rather more effectively than do wheels with worn lugs. On the other hand, their grip is not quite so effective as that of wheels equipped with good lugs. The resistance to traction, however, when pneumatic tyres are used, is perceptibly less than in the case of wheels with lugs, thereby enabling many operations to be carried out at higher speed.

Many tests of the efficiency of pneumatics have been carried out in different parts of the world, principally in America. In one case trials were conducted for the purpose of comparing the performance of machines equipped with steel and pneumatic tyres. Two similar tractors were provided respectively with the two sets of wheel equipment and carried out the same kind of work in the same field.

The tests were made mainly on dry and dusty ground. Fuel consumption figures for the pneumatic-tyred outfit ranged from 66.3 per cent. to 106.5 per cent, of those for the steelwheeled machine and acreage figures from 85.9 per cent. to 136.3 per cent, according to the work carried out.

Pneumatic tyres probably showed an overall advantage of 10 per cent.,

under the particular conditions worked. On wet ground rubber tyres slipped and could not be used without lug chains.

In another test, measurenients were taken of the area covered, fuel consumption, rolling resistance and drawbar pull on three different types ot soil for ploughing and discing. One agrimotor carried out half of each set of work on steel wheels and the other half on pneumatic tyres.

The latter equipment were more efficient at high speeds, but the relative effects were modified by speed, load and ground conditions, and the decreased rolling resistance of these was the largest factor for their increased efficiency. Slippage of the rubber tyres was 16.6 per cent less than that of steel wheels and the fuel saving averaged 13 per cent.

Similar conclusions are arrived at in most of the American tests. There seems to be a general advantage in favour of the pneumatic tyre. In one case of tests on a fairly large scale, the report states' that the tractive adhesion of rubber tyres is mainly frictional, and this is dependent on the weight of the machine and the coefficient of friction of the ground.

The limit of efficiency becomes lower as the moisture content in the soil increases, and on a soil containing colloidal and organic matter, rather than sand. As a consequence, it is stated, rubber tyres must be more valuable in regions of limited rainfall than in humid regions.

Harvesting and haulage operations are better carried out with rubber tyres than with steel wheels, and, taken generally, there is a small economy in fuel consumption in all work where the tyres will function.

The issue of Agricultural Engineering for February, 1934, contains an article of special interest, as it gives particulars of comparative tests of

both pneumatic low-pressure tyres and "zero-pressure," or cushion rubber, tyres with steel wheels. The performances of both types were similar, with an increase of 40 per cent. of the h.p.-hours per gallon of fuel over the steel wheels.

The effect on wheel slip of varying pressure in the pneumatic tyres, and

altering the weight carried by the tyres, was measured, and as the tests were carried out under ploughing conditions the slippage of land and furrow wheels was separately studied and corrected for the reduction in rolling radius due to the transfer of weight.

It was concluded that no advantage was gained by increasing the weight on the tyres above a definite value, and this critical value is smaller for tyres having a lower air pressure, thus indicating that one of the chief criteria for traction is a definite area of ground contact. Similarly, the traction falls off sharply when the moisture in the ground rises above a definite point.

In another series of tests of the low-pressure . and cushion tyre, the general results were the same, and there does not appear much to choose between the two types. In favour of the cushion tyre, however, it is stated that it did not need inflation, was not subject to puncture troubles, and gave less bounce.

A summary of tests made in 14 States of America is given in the issue

of the 'Implement and Tractor Trade Journal for March 24, 1934. Generally uniform conclusions are reached, the important points being as follow :—(1) Greater efficiency at higher speeds, owing to the decreased rolling resistance, which was about 47 per cent. of that of steel wheels. (2) The slippage was approximately 16,6 per cent. less than that of steel wheels. (3) Jarring and vibration were eliminated. (4) Some field conditions caused bouncing and made the machine more difficult to handle. (5) The saving in fuel varied from about 13 per cent. when ploughing to 20 per cent. when cultivating. (6) The best pressitre for front tyres was 26 lb.