FARM VEHICLE

Page 82

Page 83

Page 84

If you've noticed an error in this article please click here to report it so we can fix it.

BODIES

for many

purposes

Catering for the Needs of the General Farmer, the Livestock Breeder, the Market Gardener and the Agricultural Retailer

..

FOR general purposes the farmer requires a vehicle which will carry farm products and supplies, as well as livestock. A hinged-sided tipping lorry is a good basis for any superstructure which is necessary to increase the height of the body and to give protection from the weather.

Even with a small lorry the sides ok: the body should hinge in two separate portions. This arrangement is of value when livestock is carried in only the front or rear portion of the vehicle. Dividing the side in this way necessitates a central standard, which may be fixed or removable. The centre standards may support a gate or cross-partition.

The general-purpose lorry has a framed and boarded front, also rear corner pillars. A load may be piled against the boarded front and the fixed corner pillars give rigidity where it is specially required.

Immediately above the hinged .28 sides is a board extending for the full length of the body. This has outside staples which support the irons for carrying two pairs of slats. These slats have staples for securing the intermediate hoops of the waterproof cover. The front board embodies the first hoop and the rear one is attached to the corner pillars, which extend to the top of the side slats.

With this design of lorry the sides may be opened independently of the top structure, whilst the slats may be fitted at the front, the rear, or for the full length of the body, with or without a corresponding number of hoops. At the back there is a waisthigh tailboard and a pair of slatted doors mounted on lift-off hinges. When livestock is carried the tailboard and doors are removed, so that a tailboard or ramp reaching to the top of the hoops may be substituted, unless a separate loading ramp is available.

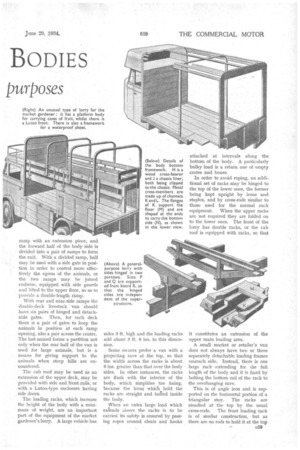

For the transport of livestock the double-decker still retains its popularity. The upper floor is frequently made in four portions. Each pair of floor sections is hinged to the body sides and folds downwards and, when in use, is supported on two detachable cross-rails.

There is the usual rear loading

ramp with an extension piece, and the forward half of the body side is divided into a pair of ramps to form the exit. With a divided ramp, half may be used with a side gate in position in order to control more effectively the egress of the animals, or the two ramps may be joined endwise, equipped with side guards and lifted to the upper floor, so as to provide a 'double-length ramp.

With rear and near-side ramps the double-deck livestock van should have six pairs of hinged and detachable gates. Then, for each deck there is a pair of gates to keep the animals in position at each ramp opening, also a pair across the centre. The last-named forms a partition not only when the rear half of the van is used for large animals, but is a means for giving support to the animals when steep hills are encountered.

The cab roof may be used as an extension of the upper deck, may be provided with side and front rails, or with a Luton-type enclosure having side doors.

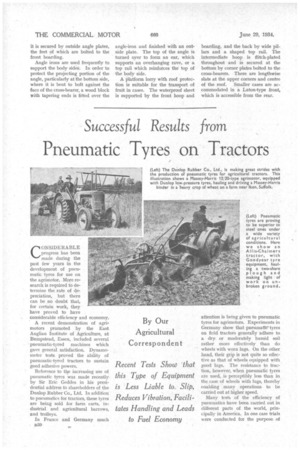

The loading racks, which increase the height of the body with a minimum of weight, are an important part of the equipment of the market gardener's lorry. A large vehicle has sides 3 ft. high and the loading racks add about 3 ft. 6 ins, to this dimension.

Some owners prefer a van with a projecting rave at the top, so that the width across the racks is about 9 ins, greater than that over the body sides. In other instances, the racks are flush with the interior of the body, which simplifies the fixing, because the irons which hold the racks are straight and boned inside the body.

When an extra large load which exTends above the racks is to be carried its safety is ensured by passing ropes around cleats and hooks attached at intervals along the bottom of the body. A particularly bulky load is a return one of empty crates and boxes.

In order to avoid roping, an additional set of racks may be hinged to the top of the lower ones, the former being kept upright by irons and staples, and by cross-rods similar to those used for the normal rack equipment. When the upper racks are not required they are folded on to the lower ones. The front of the lorry has double racks, or the cab roof is equipped with racks, so that it constitutes an extension of the upper main loading area.

A. small market or retailer's van does not always have two or three separately detachable loading frames onieach side. Instead, there is one large rack 'extending for the full length of the body and it is fixed by bolting the bottom rail of the rack to ,the overhanging rave.

This is of angle iron and is supported on the horizontal portion of a triangular stay. The racks are steadied •at the top by the usual cross-rods. The front loading rack is of similar construction, but as there are no rods to hold it at the top it is secured by outside angle plates, the feet of which are bolted to the front boarding.

Angle irons are used frequently to support the body sides. In order to protect the projecting portion of the angle, particularly at the bottom side, where it is bent to bolt against the face of the cross-bearer, a wood block with tapering ends is fitted over the angle-iron and finished with an outside plate. The top of the angle is turned over to form an ear, which supports an overhanging rave, or a top rail which reinforces the top of the body side.

A Platform lorry with roof protection is suitable for the transport of fruit in cases. The waterproof sheet is supported by the front hoop and boarding, and the back by wide pillars and a shaped top rail. The intermediate hoop is flitch-plated throughout and is secured at the bottom by corner plates bolted to the cross-bearers. There are lengthwise slats at the upper corners and centre of the roof. Smaller cases are accommodated in a Luton-type front, which is accessible from the rear.