THE LATEST PROD N STEAM WAGONS.

Page 16

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

Exclusive Information on the New 6-to constructed Engine and Gearbox, Flexibi3

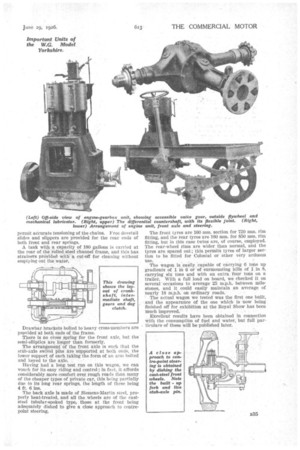

Ddel Yorkshire Steam Wagon with UnitCountershaft and Final Drive by Chains. FEWmanufacturers of steam wagons have had greater experience in this class of work than the Yorkshire Patent Steam Wagon Co., of Pepper Road, Hunslet, Leeds; in fact, they commenced building such vehicles so long ago as 1902, and their products have always been renowned for their strength and excellent durability. One particular feature which distinguishes them is the highly efficient double-ended loco-type boiler, mounted transversely at the front, and by this arrangement ensuring that, even on the steepest hills, the tubes and firebox are never uncovered.

The 6-ton W.G. model which forms the subject of the present article has been designed to take 6-ton loads up all main-road hills in top gear. Two gear ratios are, however, afforded, the gearing being of the simplest possible type, totally enclosed and running in oil, whilst the Joy valve gear involves no complication, being in this respect similar to link motion, but, in addition, gives a variable cut-off and instantaneous reverse with a long valve travel which permits high engine speeds, the valves themselves being of the piston type, and tests have shown that, owing to the-excellent balancing of the parts, engine speeds of over 1,000 r.p.m. can be attained.

In this new wagon an effort—and, we consider, a most successful one—has been made to develop a vehicle which will be suitable both for long-distance road work and the heavy haulage which is an essential feature of the machine employed on building sites, quarries, etc.

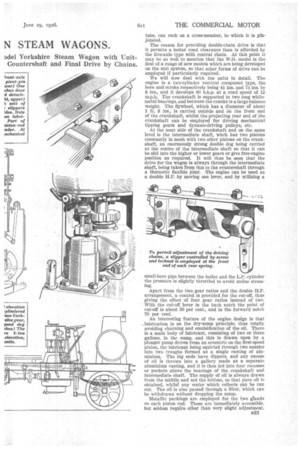

To facilitate maintenance and repair, accessibility is a matter which has received great attention. For in stance, the countershaft can be dropped in 10 minutes or completely dismantled in under half an hour, and, whilst the boiler is now enclosed by a bonnet, this has not affected its accessibility, for the bonnet is hinged at its lower edge, and can be lowered on to supporting chains so that the smokebox doors can be fully opened.

The engine and gearbox unit is carried vertically in the cab in the position to which users of Yorkshire wagons have become accustomed, and by lifting up the driver's seat and removing a cover at the side of the crankcase the whole of the motion work is available for inspection.

The upper half of the crankcase is of cast iron, and this carries the bearings and caps for the crankshaft and intermediate shaft, so that by merely dropping the aluminium sump these are immediately available for further inspection or can be removed without disturbing other parts.

It is essential in a vehicle designed for arduous work to minimize the effect of frame torsion, so in the W.G. wagon the main units are all three-point mounted, • the front cross-member for the engine swivelling in brackets on the side members, whilst at the point of support of the engine allowance is also made for movement. At its rear the crankcase is, of course, bolted firmly to a cross-member.

The countershaft has full three-point suspension, being carried in spherical sockets at the sides, whilst the front pertion, which is extended to form a short torque

tube, can rock on a cross-member, to which it is pitjointed.

The reason for providing double-chain drive is that it permits a better road clearance than is afforded by the live-axle type with central chain. At this point it may be as well to mention that the W.G. model is the first of a range of new models which are being developed on the unit system, so that other forms of drive can be employed if particularly required.

• We will now deal with the units in detail. The engine is a two-cylinder vertical compound type, the bore and stroke respectively being 41 ins. and 71 ins. by 8 ins., and it develops GO b.h.p. at a road speed of 12 m.p.h. The crankshaft is supported in two long whitemetal bearings, and between the cranks is a large balance weight. The flywheel, which has a diameter a about 1 ft. 8 ins., is carried outside and on the front end of the crankshaft, whilst the projecting rear end of the crankshaft can be employed for driving mechanical tipping gears and dynamo-driving pulleys, etc.

At the near side of the crankshaft and on the same level is the intermediate shaft, wlich has two pinions constantly in mesh with two other pinions on the crankshaft, an enormously strong double dog being carried at the centre of the intermediate shaft so that it can be slid into the higher or lower gears or give free-engine position as required. It will thus be seen that the drive for the wagon is always through the intermediate shaft, being taken Trom this to the countershaft through

• a Hermetic flexible joint. The engine can be used as a double HI'. by moving one lever, and by utilizing a

small-bore pipe between the boiler and the L.P. cylinder the pressure is slightly throttled to avoid undue stressing.

Apart from the two gear ratios and the double H.P. arrangement, acontrol is provided for the cut-off, thus giving the effect of four gear ratios instead of two. With the cut-off lever in the back notch the point of cut-off is about 50 per cent., and in the forward notch 70 per cent.

An interesting feature of the engine design is that ,lubrication is on the dry-sump principle, thus totally avoiding churning and emulsification of the oil. There is a main body of lubricant, consisting of two or three gallons, in the sump, and this is drawn upon by a plunger pump driven from an eccentric on the first-speed pinion, the lubricant being squirted through two nozzles into two troughs formed as a single casting of aluminium. The big ends have dippers, and any excess of oil is thrown into a gallery made as a separate aluminium casting, and it is then led into four recesses or pockets above the bearings of the crankshaft and intermediate shaft. The supply of oil is always drawn from the middle and not the bottom, so that pure oil is obtained, whilst any water which collects can be run out. The oil is also passed through a filter, which can be withdrawn without dropping the sump.

Metallic packings are employed for the two glands on each piston rod. These are immediately accessible, but seldom require other than very slight adjustment. 1333

An easy means of adjustment is provided for the travel of the piston valves.

Cylinder lubrication is carried out in the usual manner by an engine-operated• mechanical lubricator mounted above the cylinders, where it can be kept warm.

The standard gear ratios afforded are 4-f to 1 and 12 to 1. The gears themselves are cut in SiemensMartin steel.

It is difficult to say which of the two—engine or

boiler—is the more important, but, in any ease, the boiler has received just as close attention as the former. Its safe working pressure is 215 lb., but it is tested to 330 lb. and is lagged with asbestos and sheet steel. The chief modifications in this unit are that the exhaust jets in. the doors have been dispensed with and a single jet employed in the chimney. Bench tests have shown that this gives nearly 10 per cent. greater efficiency, but the main reason is that it lends itself better to the layout of the wagon.

Superheaters are mounted within the smokeboxes, and so arranged that they can easily be removed. This is, however, only necessary when the outer ends of the tubes require expanding—a most infrequent occurrence. The new type smokebox doors are of more substantial construction and filled with asbestos, and each possesses a groove with packing which makes a joint with the end of the tube plate. In equipping the boiler with these fittings, they are not mounted direct upon the shell, as this involves very accurate fitting of faces, packing, etc., if trouble is to be avoided. Employing proper flange,s formed in one with the shell enables fiat and easily made joints to be utilized. A small but interesting point is that the injector is mounted on the boiler, so that its pipe is internal.

All the controls, the boiler and the engine are so arranged that the cab is remarkably free from projections. It can be entered from either side, there being a gangway right through. At the off side of the cab is a capacious bunker, the forward portion of which forms the seat for the second man, who extracts the fuel by using a shovel between his feet. All the controls are handy to the driver. The hand brake and cut-off control, lever are at his right, whilst there are a hand steam va,,lve or throttle and the change-speed lever at the left, close to the engine, foot actuation of the throttle also being permitted. Both the hand and foot brakes operate direct on the rear-wheel drums, the shoes being mounted side by side ; they have full pivots and are not merely held in position by springs. The brake camshafts have self-lubricating bushes and the brakes themselves are uncompensated. Fabric friction material is used on both.

Somewhat unusual construction is employed for the countershaft, as the differential of this has no cage in the ordinary sense of the term. The differential main pinions are solid with their shafts, whilst the planet pinions are carried by a spider ; both sets are of chromevanadium steel. Oil grooves in the shaft bushes are so arranged as to return oil to the centre, from which it is thrown into large reservoirs above the inner bearings.

There are no ball or roller bearings throughout the chassis,' The front-wheel bushes are fixed, whilst those for the rear wheels are of the floating type. The axle thrust-washers are of steel and bronze.

Another new feature of this chassis is that the driving and braking stresses are taken through the top leaves of the rear springs, following the practice adopted in many petrol-motor vehicles, and, to prevent any possibility of the axle moving, patent Woodhead springs of the divided top-leaf type are employed, these being especially designed for the new wagon. For each rear spring front anchorage there is a dovetail slide carrying a slipper with a stout adjusting screw to permit accurate tensioning of the chains. Free dovetail slides and slippers are provided for the rear ends of both front and rear springs.

A tank with a capacity of 180 gallons is carried at the rear of the rolled steel channel frame, and this has strainers provided with a cut-off for cleaning without emptying out the,water.

Drawbar brackets bolted to heavy cross-members are provided at both ends of the frame.

There is no cross spring for the front axle, but the semi-elliptic.s. are longer than formerly.

The arrangement of the front axle is such that the stub-axle swiVel pins are 'supported, at both ends, the lower support of each taking the form of an arm bolted and keyed to the• axle. '

Having had a long test run on this wagon, we can vouch for its easy riding and control; in fact, it affords considerably more comfort over rough roads than many of the cheaper types of private car, this being partially due to its long rear springs, the length of these being 4 ft. 6 ins.

The back axle is made of Siemens-Martin steel, properly heat-treated, and all the wheels are of the caststeel tubular-spoked type, those at the front being adequately dished to give a close approach to centrepoint steering.

The front tyres are 160 mm. section for 720 ram. rim fitting, and the rear tyres are 160 mm. for 850 mm. rim fitting, but in this case twins are, of course, employed. The rear-wheel rims are wider, than normal, and the tyres are spaced out; this permits tyres of larger section to be fitted for Colonial or other very arduous use.

The wagon is easily capable of carrying 6 tons up gradients of 1 in 6 or of surmounting hills of 1 in 8,• carrying six tons and with an extra, four tons on a trailer. With a full load on board, we checked it on several occasions to average 25 m.p.h. between milestones, and it could easily maintain an average of nearly 18 m.p.h, on ordinary roads.

The actual wagon we tested was the first one built, and the appearance of the one which is now being finished off for exhibition at the Royal Show has been much improved.

Excellent results have been obtained in connection With the consumption of fuel and water, but full particulars of these will be published later.