Contributions from Drivers and Mechanics.

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY for the Best Communication Received, and One Penny a Line of ten words for any thing else published.

Save Your Saw Blades.

The sender of the following etrmmunication has been awarded the 10s. prize this week.

[881] " F.13," (Epsom) writes :—" It frequently happens that hacksaw blades get broken long before they are anything like worn out, and it has always an noyed me to have to throw away blades, which are still capable of cutting, just because they have been accidentally broken early in their career. I have now found a way of using these up. I bolt a number of these, say, five or six, together, with a small screw and nut at one end ; the other ends I bind together by means of stout cord covered with a wrapping of insulating tape, in order to form a handle. This makes a first-class rasp, which I find particularly useful, for instance, for cleaning tire tubes and patches before repairing. No doubt many other uses for it will occur to your readers. It is the sort of tool that it pays any mechanic who has a lot of odd jobs to do to keep in his tool-box. Lots of men are very clumsy indeed when using a hacksaw ; they don't trouble to learn how to hold it, and they often hold the frame too firmly."

Some Soldering Tips and Other Things.

[892] " H.H.S." (Luton) writes :—" I submit to you herewith a number of tips which I think may be useful to many of my fellow readers. Few people know, I think, that beeswax makes a perfect lubricant when threads are being cut on copper pipes. The wax is merely rubbed on to the surface which is being cut, and, as a matter of fact., serves its purpose much better than oil.

" Many fitters in garages and repair shops must have a lot of unusual and awkward soldering jobs to do. Perhaps a few wrinkles on this subject may not

be out of place on the '1). and M.' pages. Cast iron can be successfully tinned and soldered with the aid of a flux composed of zinc chloride, the solution to be made of five parts zinc chloride, four parts alcohol,

and one part glycerine. The alcohol readily dissolves the zinc chloride, and the glycerine makes it sticky, so that it adheres more readily to the articles which arb to be soldered. The addition of alcohol has two ad vantages: not only does it dissolve the zinc, but when it is applied to the work it takes fire when the job is hot enough. It therefore acts as a temperature indi cator, and it also helps to keep the work hot while it is being soldered. This solution is best applied with a brush. It will, as a rule, be found useful to keep a supply of it ready in the shop ; it is best stocked in a glass-stoppered bottle ready for use.

" When the surfaces of two steel or iron parts fit well together, the best way to join them is to use a piece of tin foil. After the surfaces have been cleaned,

and have been closely fitted, the tin foil is placed between the two faces of the work, and these are

bound together with wire or are clamped in position. My special flux is used as required. The job is then heated with a blow pipe, until the tin foil melts and joins the two parts together. Care must, of course, be taken not to disturb the job until it has cooled properly.

" One other thing I should like to point out, and in this case it is an illustration of the usefulness of many of the tips that appear in the 'CM.' Some time ago I was assembling an engine, and when finishing it I found that a On. hole right between the two pairs of cylinders had not been tapped. This meant that I should have to take one pair of the cylinders off, as there was no room to get a tap and turn it between

the two. Luckily I remembered a tip which I had

seen in the 'C.M.' some time previously. I found a tap that had been broken, and T ground it down quite short. With the aid of a 4-in. nut, which I had squared out to fit the top of the tap, I was then able to turn it with a spanner without removing the cylinder. This saved me a great deal of trouble, and about two hours of extra work."

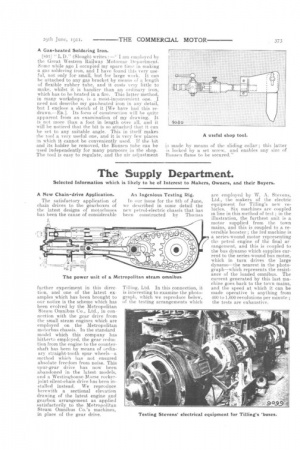

A Gas-heated Soldering Iron.

[S9:3j " L.D." (Slough) writes :—" I am employed by the Great Western Railway Motorcar Department. ;Some while ago I occupied my spare time in making a gas soldering iron, and I have found this very useful, not only for small, but for large work. It can be attached to any gas bracket by means of ;i. length of flexible rubber tube, and it costs very little to make, whilst, it is handier than an ordinary iron, which has to be heated in a fire. This latter method, in many workshops, is a most-inconvenient one. . I need not describe my gas-heated iron in any detail, but I enclose a sketch of it [We have had this redrawn—ED.]. Its Its form of construction will he quite apparent from an examination of my drawing. It is not more than a foot in length over all, and it will be noticed that the bit is so attached that it can be set to any suitable angle. This in itself makes he tool a very useful one, and it is very few places in which it cannot be conveniently used. Ti the bit and its holder be removed, the Bunsen tube can be used independently for many purposes in the shop. The tool is easy to regulate, and the air adjustment

is made by means of the sliding collar ; this latter is locked by a set screw, and enables any size of Bunsen flame to be secured."