TRANSPORT Y DEGREES

Page 50

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

By John Savage, A.I.R.T.E. THE distribution of ice-cream by yoad presents many problems. Dealing with seasonal, daily and even hourly changes in consumption necessitates a flexible transport organization that can be almost instantaneously Moulded to meet current demands,

Distribution takes three distinct forms; bulk delivery. to depots, distribution to retailers and direct consumer sales. The vehicles are carefully constructed to meet. the requirements of each. Payloads are low, compared with those in most trades, as the equipment and insulation used to hold the temperature below freezing point add several hundredweight to the unladen weight.

Refrigeration engineers, bodybuilders and ice-cream manufacturers are constantly striving to reduce the unladen weight and improve the refrigeration efficiency of these highly specialized Vehicles. The type of insulating material used and the way in which it is employed play a big part in maintaining a low ternperature, but factors other than sheer thermal insulation influence the type of material adopted.

Refrigeration Essential

For ice-cream, insulation alone, such as is normally used for meat, fish and other perishable goods, is inadequate. A refrigerant must be employed to ensure that ice-cream delivered at the end of a day's journey is still hard, and this must be so on the hottest summer day. , When bulk supplies are conveyed in well-insulated vehicles, the problems arc not great. Likewise, the direct sale of ice-cream from refrigerated containers carried in small vehicles presents few special difficulties. Complications arise on services distributing ice-cream to retailers. To meet the requirements of delivery schedules, reasonable loads must be carried and doors must be designed to permit easy and quick unloading, whilst avoiding any great loss of cold air.

Many deliveries are made on the round and the frequent opening of the door may menace otherwise satisfactory refrigeration. It is this class of refrigerated transport that is receiving a great deal of attention at the moment and this summer has seen the introduction of several new vehicles which embody the latest ideas on the subject, details of which are being preciously guarded.

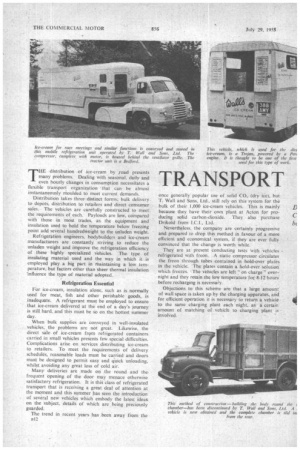

The trend in recent years has been away from the once generally popular use of solid CO, (dry ice), but T. Wall and Sons, Ltd., still rely on this system for the bulk of their 1,000 ice-cream vehicles.. This is mainly because they have their own plant at Acton for producing solid carbondioxide. They also purchase Drikold from I.C.I., Ltd.

Nevertheless, the company are certainly progressive and prepared to drop this method in favour of a more efficient and economical system. if they are ever fully convinced that the change is worth while.

They are at Present conducting tests vith vehicles refrigerated with freon. A static compressor circulates the freon through tubes contained in hold-over plates in the vehicle. The plates contain a hold-over solution which freezes. The vehicles are left 7 on charge overnight and they retain the low temperature for 8-12 hours before recharging is necessary.

Objections to this scheme are that a large amount of wall space is taken up by the charging apparatus, and for efficient operation it is necessary to return a vehicle to the same charging plant each night, as a certain amount of matching of vehicit to charging plant is involved.

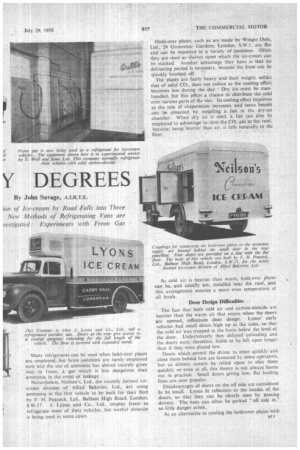

Many refrigerants can be used when hold-over plates are employed, but brine .,solutions are rarely employed now and the use of ammonia has almost entirely given way to frcon, a gas which is less dangerous than ammonia in the event of leakage.

Nevertheless, Neilson's, Ltd., the recently formed icecream division of Allied Bakeries. Ltd., are using ammonia in the first vehicle to be built for their fleet by F. H. Peacock, Ltd_ Balham High Road, London, S.W.I7. J. Lyons and Co.. Ltd., employ freon to refrigerate most of their vehicles, but methyl chloride is being used in some cases. Hold-over plates, such as are made by Winget Dole, Ltd:. 24 Grosvenor Gardens, London, S.W.1, are flat and can be mounted-in a varieiy of positions. Often they are used as shelves uPoil which the ice-cream can be stacked. Another advantage they have is that no defrosting period is necessary, because the frost can be quickly brushed off.

The plates are fairly heavy and their .weight, unlike that of solid CO,, does not reduce as the cooling effect becomes less during the day. Dry ice must be manhandled, but this offers a chance to distribute the cold over various parts of the van. Its cooling effect improves as the rate of evaporation increases. and some benefit can be obtained by installing a fan in the dry-ice chamber. When dry ice is used, a fan can also be employed to advantage to raise the CO, gas to•the roof, because, being heavier than air. it falls haturally.to the floor.

As cold air is heavier than warm, hold-over plates can be, and usually are, installed near the roof, and this arrangement ensures a more even temperature at all levels.

Door Design Difficulties

The fact that both cold air and carbon-dioxide are heavier than the warm air that enters when the doors are opened, influences door design. Lyons' early vehicles. had small doors high up in the sides, so that the cold air was trapped in the basin below the level of the door. Unfortunately they delayed unloading and the doors were, therefore, liable to be left open longer than if they were placed low.

Doors which permit the driver to enter quickly and close them behind him are favoured by some operators, but as drivers cannot be relied upon to shut them quickly, or even at all, this theory is not always borne out in practice. Small doors giving low, flat loading lines are now popular.

Disadvantages of doors on the off side are considered lo be small. Lyons fit reflectors to the insides of the doors, so that they can be clearly seen by passing drivers. The vans can often be parked "off side in," so little danger arises.

As ap alternative to cooling the hold-over plates with 1313 a static refrigerating plant, a compressor, driven by an electric motor, can be mounted on the vehicle. Several companies are trying this scheme because the closedcircuit, self-contained unit is attractive to refrigeration engineers. Such a vehicle has only to be connected to the mains supply to bring its temperature down.

However, for small, and even medium-sized vehicles, the increase in unladen weight is undesirable, especially when it is necessary to keep in the 30 m.p.h. class. On large vehicles of the type used as mobile cold stores at race meetings, fetes and the like, the compressor can be driven by a small petrol or oil engine. The unladen weight in these circumstances is not so critical.

Light Alloy Too Costly

Refrigerated bodies are normally built on wooden frames. Light-alloy frames have been used, but they are generally too expensive to warrant their use for the sake of the slight reduction in unladen weight obtained.

Usually the inner shell is constructed of aluminium sheet, the insulating material is packed round it between the frame members (which are normally staggered) and the outer shell is then added. Sometimes an air gap is left between the outer skin and roof of the body, and the outside layer of the insulated compartment. Condensation in the gap is liable to cause the wood to rot unless the air can circulate freely through it.

This method of construction has been employed to advantage by Walls, who are now building insulated containers which slip into conventionalstyle bodies. Provision is made to open the body up to its full width at the rear, but otherwise it is standard.

Walls build nearly all their insulated bodies themselves, and use Onazote insulating material almost exclusively. This material, which is made by the Expanding Rubber Co., Ltd., Mitcham Road, Croydon, Surrey, is extremely efficient as an insulator. It is light and non-absorbent. It is produced in slabs of uniform thickness and must be cut to size and fitted together with great care. The edges must be joined with bitumen, as the material will not compress to seal the gaps. Strict supervision is usually required to ensure that the joints are all properly sealed without using an excess of bitumen, as this can easily add a great deal to the unladen weight.

New Plastics for Insulation

Several new plastics insulating materials are now available. These include Jablow, which is produced by Plastic Industries, Ltd., Mill Lane. Wadham, Croydon, and Plactcell, made by the Airscrew Co., and Jiewood, Ltd., Weybridge, Surrey. All are based on the principle of a mass of small, totally enclosed pockets of air.

Fibre-glass can be employed as a heat-insulating material, but in its normal form, as used for sound insulating and damping, it is liable to compress through being shaken down. This is a great disadvantage in -the case of lorry sides, but the shortcoming has been substantially overcome by impregnating the fibre with resin. In this form, the material is firm, but it can be B14 bent, crushed and packed into crevices. Normand, Ltd., Cumberland Avenue, London, N.W.10, who build refrigerated vehicles for J. Lyons and Co., Ltd., favour this material. It is clean to handle and, as no sealing compound is required, weight is reduced, although a greater thickness of Material is normally used.

As fibre-glass absorbs moisture, even when treated with resin, there is a slight risk of the wooden framework rotting through condensation. The danger is not great, and little or no trouble appears to have been experienced in this direction.

The optimum thickness of insulation does not yet appear to have been determined. Onazote is normally used in two layers 2 in. thick for ice-crearn vehicles, but up to 8 in. have been employed in certain cases. Ordinary insulated vehicles normally have 1 in. of Onazote.

Fibre-glass is usually laid a little thicker. One bodybuilder will put extra insulation on the floor, another will put the extra thickness on the roof, and others will use a uniform thickness of insulation throughout. Rule of thumb governs current practice, but some technical investigations are being carried out for Walls to determine scientifically the optimum thickness of insulating materials for certain operating conditions.

Express Dairies, Ltd., recently took delivery of the first of a number of refrigerated vans known as the Autofreezer. To the design of Penfold and Partners, 120 Victoria Street, London, S.W.1, a compressor is carried, this being mounted on and driven by the engine of the vehicle. Hawson, Ltd., Sunbury-on-Thames, built the light-alloy body, which is of the doubleskinned type. The space between the inner and outer skins being filled with insulating material.

Interest in refrigerated vehicles is likely to grow as a result of the increasing popularity of quick-frozen foods. Demands for fresh, good-quality meat and fisit may also cause more transport organizations to adopt refrigerated vehicles for their conveyance.