THE LUBRICATION OF CHASSIS PARTS.

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

A Constructive Criticism of Everyday Methods, With Suggestions Based Upon Experience, for Their Improvement.

THE ARTICLE which appeared in the issue of The Commercial Motor for July 8th last on the subject of chassis parts lubrication gave a great deal of useful information, but it was not written in a critical spirit. I cannot help thinking that a little constructive criticism of the methods of introducing lubricants to the various parts, also the nature of the lubricants, might be of interest. There are several debatable points in connection with the lubrication of certain moving parts on a chassis, and it would be very interesting if those who have had extensive experience in the maintenance of lorries of various makes would give their opinions upon the best way of securing an adequate supply of lubricants to these parts.

I do not propose to deal with engine, gearbox, or final main drive lubrication, but to confine myself to the lubrication of such parts as shackles, steering, and brake details, and universal joints.

The question as to whether grease is a suitable lubricant for such parts has been discussed, but has not been finally settled. In my opinion, grease is not suitable, no matter by what means it may be introduced. Such parts as those under discussion do not make a complete revolution in relation to their bearings. A slight oscillatory movement of only a few degrees of angle, and under very heavy pressure for their area, is the condition under which such parts work. Now, this is one of the most difficult conditions under which a lubricant can be introduced, and -under which it can continue to do its work. It is obvious that, no matter with what pressure grease is forced into such beatings, such as those of shackles, it would be impossible for it to raise the weight of the chassis, and, by so doing, to find its way where it is required, namely, between the surfaces of the pin and its bearing. It may be said that grease will remain between heavily loaded surfaces for a longer period than oil will, but the question is, after the first greasing, carried out whilst the parts are being assembled, do we ever get the grease to go where it is wanted again ?

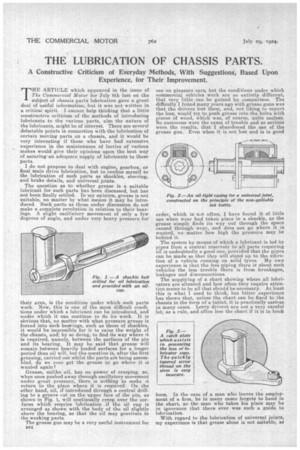

Grease, unlike oil, has no power of creeping, so, when once pushed away through oscillatory movement under great pressure, there is nothing to make it return to the place where it is required. On the other hand, oil, if introduced through a central drilling to a groove cut on the upper face of the pin, as shown in 'Fig. 1, will continually creep over the surfaces. which require lubrication if the oil cup is arranged as shown with the body of the oil slightly above the bearing, so that the oil may gravitate to the working parts.

The grease gun may be a very useful instrument for ni1,1

use on pleasure cars, but the conditions under which commercial vehicles work are so entirely different, that very little can be gained by comparison. The difficulty I found many years ago with grease guns was that the drivers lost them, and, not liking to report the loss, would try to push grease into the holes with pieces of wood, which was of course, quite useless. So numerous were the eases of trouble and so seriouS were the results, that I abandoned the use of the grease gun. Even when it is not lost and is in good order, which is not often, I have found it of little use When wear had taken place in a shackle, as the grease simply finds its way out through the space caused through wear, and does not go where it is wanted, no matter liow high the pressure may he behind it.

The system by means of which a lubricant is led by pipes from a central reservoir to all parts requiring oil is undoubtedly a good one, provided. that the pipes can be made so that they will stand up to the vibration of a vehicle running on solid tyres. My own experience is that the less piping there is about such vehicles the less trouble there is from breakages, leakages and disconnections. The supplying of a chart showing where all lubricators are situated and how often they require attention seems to be all that should be necessary. At least this is what I used to think, but bitter experience has shown -that, unless the chart can be fixed to the chassis in the form of a tablet, it is practically useless in many eases. Lorry drivers are not a very careful lot, as a rule, and often lose the chart if it is in book

form. In the case of a man who leaves the employment of a firm, he in many eases forgets to hand in the chart, so the man who takes his place may be irk ignorance that there ever was such a guide to lubrication.

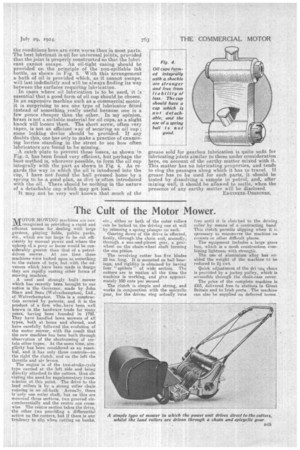

With regard to the lubrication of universal joints, my experience is that grease alone is not suitable, as the conditions here are even worse than in most parts. The best lubricant is oil for universal joints, provided that the joint is properly constructed so that the lubricant cannot escape. An oil-tight casing should be provided on the principle of the non-spillable ink bottle, as shown in Fig. 2. With this arrangement a bath of oil is provided which, as it cannot escape, will last indefinitely and will be always finding its way between the surfaces requiring lubrication. In eases where oil lubrication is to be used, it Is essential that a good form of oil cup should be chosen. In an expensive machine such as a commercial motor, it is surprising to see one type of lubricator fitted instead of something really useful because one is a few pence cheaper than the other. In my opinion, brass is not a suitable material for oil cups, as a slight knock will loosen them. The short screw, often very taper, is not an efficient way of securing an oil cup ; some locking device should be provided. If any doubts this, one has only to make a practice of examining lorries standing in the street to see how often lubricators are found to be missing.

A catch plate to prevent these losses' as shown in Fig. 3, has been found very efficient, but perhaps the best method is, wherever possible, to form the oil cup integrally with the part as shown in Fig. 4. As regards the way in which the oil is intoduced into the cup, I have not found the ball pressed home by a spring to be a good plan, as dirt is often introduced with the oil. There should be nothing in the nature of a detachable cap which may get lost.

It may not be very well known that much of the grease sold for gearbox lubrication is quite unfit for lubricating joints similar to those under consideration here, on account of the earthy matter mixed with it This matter has no lubricating properties, and tends to clog the passages along which it has to travel. If grease has to be used for such parts, it should be tested by dissolving a sample in petrol, and, after mixing well, it should be allowed to settle, when the presence of any earthy matter will be disclosed. ENGINEER-DESIGNER.