FauThDrivers& Mechanics

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Light Up Your Lamps At 8.52 on Thursday; 8.51 on Friday ; 8.49 on Saturday • 8.47 on Monday ; 8.45 on Tuesday ; 8.43 on Wednesday.

The Alignment of Used-chassis Components.

The sender of the following communication has been awarded the .10s. prize this week.

[1652] " J.C.H." (Bristol) writes :—" After some years of use the framework of even the best chassis is liable to develop a kink just in front of the driver's seat. This is greater or less according to the strength of the frame relative to the load which the chassis carries. As a consequence the alignment of the engine and gearbox suffers. The result is a certain lack of efficiency in the transmission, and it is up to the

garage people to remedy this so far as is possible. It would perhaps help if I state a particular case and my method of effecting improvement.

'r•f,` The example I have in mind is a 25 h.p. touring car chassis built some years ago. The clutch was of the plate type, and only one universal joint was fitted between this component and the gearbox. The frame was, of course, not designed for the rough-and-tumble work of a commercial vehicle, and the consequent considerable camber in it had the effect of throwing the engine and the gearbox out of line. The difficulty in allowing for this deflection was principally owing to the fact that naturally the frame would give more when under the full load than when running light, and when the chassis was stripped for overhaul the deflection was even less than when it was carrying the normal bodywork. I commenced by marking the engine-case and gearbox by lines drawn at a given distance from the centres of the crankshaft and gearshaft respectively. I placed the body, on the chassis and stretched a wire over two boxes so that it was horizontal and cleared by a few inches that portion of the, mechanism which extended' nearest the ground: As the chassis was loaded for approximately 90 per cent. of its mileage I aligned it up in that con. dition so that after packing the feet of the: engine and gearbox, the distance between the wire and the lines marked on the casing A, B, C, D, were equal.

Plugging Holes. j1653] " E.H." (Widnes) writes :—" When cores and other holes in castings are to be filled up a-common practice is to tap out the hole with ti gas tap and plug it up with a portion of a threaded bar of the correet size.

" I am ot opinion that this is neither the best nor cheapest method.x:If the hole is to be plugged for the sake of appeararibe only, I think it would be sufficient if it were drilled out and a plug turned to fit and driven in...Af it must be sufficiently tight to hold either steam or other pressure, reamer the hole out and drive the plug in tightly.

Replacing Blind Housings.

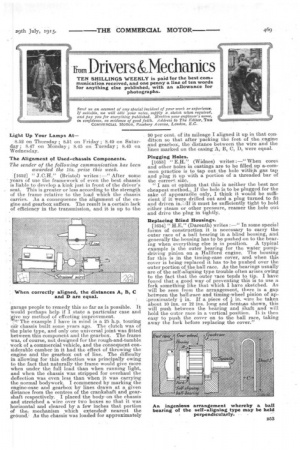

[1654] " H.E." (Darenth) writes :—" In some special forms of construction it is necessary to carry the outer race of a ball bearing in a blind housing, and generally the housing has to be pushed on to the bearing when everything else is in position. A typical example is the outer bearing for the water pumpdriving pinion on a Hallford engine. The housing for this is in the timing-case cover, and when this cover is being replaced it has to«.be pushed over the outer portion of the ball race. As the bearings usually are of the self-aligning type trouble often arises owing to the fact that the outer vace tends to tip. I have fund that a good way of preventing this is to use a fork .something like that which I have sketched. As will be seen from the arrangement, there is a gap between the balloace and timing-wheel pinion of ap;proximately in. If a piece of in. wire be taken about 10 ins. or 12 ins, long and bentf,as shown, this will push between the bearing and Shaft and will hold the outer race in a vertical position. It is then easy to push the cover on to the ball race, taking away the fork before replacing the cover."