The Bromley. Peters Chassis.

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

An American-assembled Chassis for 85-cwt. Gross Loads. Designed by an English Engineer so as to be Suitable fur British Users.

Although an American chassis, and an assembled one at that, the Bromley-Peters has the advantage that its components have been selected by an engineer with years of experience of British requirements behind him—we refer to Mr. Bodman, at one time partner in the firm of Simpson and Bodinan, Manchester; and lately engaged as automobile engineer to Peters and Sons, Ltd., of King Street, St. James's. He is now in the State, where he designed this machine and where he is now in charge of a factory which will be specially interested in the mannfaCture of this Chassis for Peters arid Sons, Ltd.

•

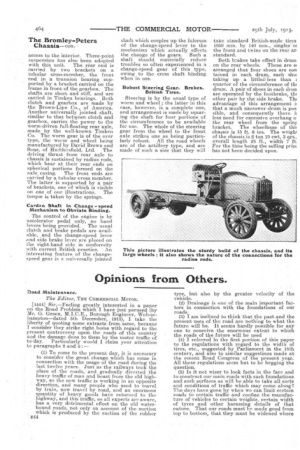

Gross Load Capacity, 85 cwt. Strong Frame.

The chassis itself is to carry 85 cwt. gross ; nominally it is a 3A-ten machine, and on this an allowance of 15 cwt. is made for bodywork. If the body is lighter than this, the load, of course, may be incr'eased accordingly. Its appeararlee is striking, inasmuch 'asthe wheelbase is longer than usual and the frame is particularly deep and well braced.

Up-to-date Engine Design.

The engine fitted is made by the Continental Engineering Co., of America, and is 4ene of their commercial type power units. It is of fairly substantial construction, and may be stated to have incorporated in its construction all those features which are now agreed upon as being necessary in an up-Lk:el:late high-grade component of this sort, such as, for example, three-point suspension, the front end being carried by a, bearing in a _cross member which runs from side to side of the main frame ; the rear end_ is borne by two substantial arrnS, with journalsat_their extremities, carried on special brackets bolted to the main frame. The suspension is thus practically an academically-correct three-point one. Lubrication of the main bearings is pump forced, and the remainder of the moving parts are oiled by splash from a sump in the crankcase, the depth of oil in which iS indicated by a very accessible and easily visible indicator on the top of the crankcase. The cooling water is circulated by means of a centrifugal pump driven in the usual manner from the timing gear, through the medium of a universal joint. On the same side of the engine, and immediately behind this pump, is placed a high-tension magneto. A governor is provided ; this normally operates when the wagon speed approaches 15 m.p.h.

Unusual Radiator Suspension.

The radiator is a substantial one of the built-up type, with east top and bottom headers and side plates. The tubes in the model under review were flat ones, but it is proposed in the future to fit round copper tubes as in the L.G.O.C. buses. This unit is also notable for the manner in which it is suspended from the frame. Special brackets are bolted tor the front cross member, and these are carried underneath the bottom box of the radiator to which they are bolted, while thick rubber washers are inserted between. radiator and supports, so as to absorb any ex cessive vibration. '

Totally Enclosed but Accessible Plate Clutch.

A dry-plate clutch, whose dimensions are rather more than normal, takes the power from the engine and transmits it through a doubly jointed clutch shaft. This shalt, being somewhat long, is made cif tubing in order to stiffen it. The clutch, although totally enclosed, is, nevertheless, fairly accessible for examination, as there are t*o large hand-hole covers on the casing.

Four-speed Box. Shafts on Roller Bearings.

The four-speed and reverse gearbox is carried midway along the chassis. The gears are wide, the teeth of a large pitch, the arrangement of this component being such that the layslutft is vertically tlyderneath the ma.inshaft. A large handhole -cover, equal in area .to the cross section of the box, gives access to the interior. Three-point suspension has also been adopted with this unit. The rear end is carried by two brackets on a tubular cross-member, the front end in a trunnion bearing supported by a bracket carried on the frame in front of the gearbox. The shafts are short and stiff, and are carried in Timken bearings. Bcth clutch and gearbox are made by the Brown-Lipe Co., of America. Another universally jointed shaft, similar to that between clutch and gearbox, carries the power to the worm-driven full-floating rear axle, made by the well-known Timken Co. The worm gear is of the over type, the worm and wheel being manufactured by David Brown and Sons, of Huddersfield, Ltd. The driving thrust from rear axle 'to chassis is sustained by radius rods, which bear at their rear ends on spherical portions formed on the axle casing. The front ends are carried by a tubular cross member. The latter is supported by a pair of brackets, one of which is visible on one of our illustrations. The torque is taken by the springs.

Cardan Shaft in Change . speed Mechanism to Obviate Binding.

The control of the engine is by accelerator pedal only, no hand levers being provided. The usual clutch and brake pedals are available, and the change-speed lever and side brake lever are placed on the right-hand side in conformity with current British practice. An interesting feature of the changespeed gear is a universally jointed shaft which couples up the fulcrum of the change-speed lever to the mechanism which actually effects the change of the gears. Such a shaft should materially reduce troubles so often experienced in a change-speed gear of this type, owing to the cross shaft binding when in use.

Robust Steering Gear. Brakes. British Tires.

Steering is by the usual type of worm and wheel; the latter in this case, however, is a complete one, and arrangement is made by squaring the shaft for four portions of the circumference to be available for use. The whole of the steering gear from the wheel to the front axle strikes one as being particularly robust. All the road wheels are of the artillery type, and are made of such a size that they will take standard British-made tires 1050 mm. by 140 mm.' singles o] the front and twins on the rear ar standard.

Both brakes take effect in drum on the rear wheels. These are si arranged that four shoes are eon tamed in each drum, each shol taking up • a littleL less than quarter of the circumference of thi drum. A pair of shoes in each drun are operated by the footbrake, tie other pair by the side brake. Thi advantage of this arrangement i: that a much narrower drum is pos sible, and consequently there less need for excessive overhang o the rear wheel from the sprint bracket. The wheelbase of thn chassis is 15 ft. 6 ins. The weighi of the chassis is 2 ton 19 cwt. 3 qrs. overall length 23 ft., width 7 ft For the time being the selling pricE has not been decided upon.