Sideguards and under run protection are here

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

From May 1 operators will have to providE these protective measures for rigids and trailers alike. Graham Montgomerie looks E the requirements

ALTHOUGH the permitted increase to 38-tonnes gross combination weight was the item of most interest to most operators in the recent amendment to the Construction and Use Regulations, it should not be forgotten that higher weights were merely part of a complete package. This package also contained changes to axle spacing, axle loading and last, but by no means least, requirements for the fitting of sideguards and rear under-run protection.

In broad terms, on or after May 1, 1983, every semi-trailer has to be fitted with a sideguard where the distance between the leading axle and the king pin exceeds 4.5m (14ft 91n). In the case of a trailer with a dual kingpin position, the rearmost is the one to be considered.

This requirement only applies to any tractive unit/trailer combination whose gross weight exceeds 32 tons but this is only an interim stage leading up to a more embracing requirement in the future, namely that powered vehicles should be fitted with side guards as well.

The dividing line is that every vehicle with a gross weight exceeding 3.5 tonnes which is manufactured on or after October 1, 1983 and first used on or after April 1, 1984 has to be fitted with sideguards. As far as the trailer is concerned, the same applies if the unladen weight of the said trailer exceeds 1.02 tonnes and it is manufactured on or after May 1, 1983.

Before getting on to the dimensional requirements, it is worth mentioning the list of exemptions. This is quite a long list as the Department of Transport has, thankfully, realised that fitting of sideguards is a physical impossibility in certain cases.

Tractive units have been excluded from the requirement or, as the offical wording explains, "a motor car or a heavy motor car constructed or adapted to form part of an articulated vehicle." With an 80-plus gallon fuel tank, batteries and air tanks filling in the gap between the axles, there is precious little room for anybody to get caught.

Other exemptions include agricultural trailers, engineering plant, fire engines and agricultural tractors as well as a motor vehicle incapable of exceeding 24km/h (15 mph) on a level road under its own power.

One perhaps surprising exemption concerns tippers, with the official terminology referring to "a vehicle so constructed that it can be unloaded by part of the vehicle being tipped sideways or rearwards." Tippers tend to be of short wheelbase anyway, and often have a ground clearance problem on sticky sites so this is a useful exemption.

The position on who is responsible for the actual fitment of the sideguard has been clarified. Chassis manufacturers had been very twitchy about this as it added to their published kerb weights and it meant that they had to have prior information as to what type of body was going to be fitted — not always an easy task. • Exemption has thus been granted to a chassis which is being driven or towed to a bodybuilder for the bodywork or sideguard to be fitted. The actual wording here is critical; such a visit has to be "by previous arrangement" as is the case with the annual inspection. A similar exemption applies to the bare chassis if it is being driven (or towed) to a distributor or dealer for a quality or safety check.

Municipal operators will have been relieved to learn that most

of their vehicles are exern from the requirement to fit aid guards. The exemption applii to: "a vehicle designed solely f' use and used solely in conne tion with street cleansing, ti collection or disposal of reful or the collection or disposal the contents of gullies or ce.f. pools."

The final exemptions apply vehicles owned by the Secreta of State for Defence and used f naval, military and air force pi, poses and to trailers designed constructed (and not merE adapted) to carry timber, bear or girders of exceptional lengt1 The tanker was one vehicle f which the sideguard requil ment was going to cause inst. lation problems, particularly I cause of all the ho; connections. This has been cognised by the DTp and, wh such vehicles are not actua exempt, they only have to col ply "so far as is practicable."

The definition of tanker in context is important. The regu tions refer to it as: "a vehic designed solely for the carria of a fluid substance in a dos tank which is permanently fitt to the vehicle and provided w valves and hose or pipe comic tions for loading and unloE ing."

The requirement to comr "so far as is practicable" at refers to vehicles which require outriggers for additional stability during operation or for loading and unloading.

Haying got the list of exemptions out of the way, we come to the dimensional and strength requirements. When the original consultative document was put forward, the sideguard was required to withstand a force of 10kN (about one ton) without deformation. This was regarded as a fairly robust component for what was intended to protect pedestrians and cyclists and the result of the consultation has been a relaxation of the strength required in the structure.

The "production" sideguard has to be capable of withstanding a force of 2kN, with the reference test condition being an application perpendicular to any part of the surface by a ram, the face of which is circular and not more than 220mm (8.7in) in diameter.

Deformation is permitted but within certain limits which vary according to the position of the impact on the sideguard. No part of the sideguard which is less than 250mm (9.8in) from its rearmost part is permitted to deflect by more than 30mm (1.2in), A deflection of up to 150mm (5.9in) is allowed on any other part of the sideguard.

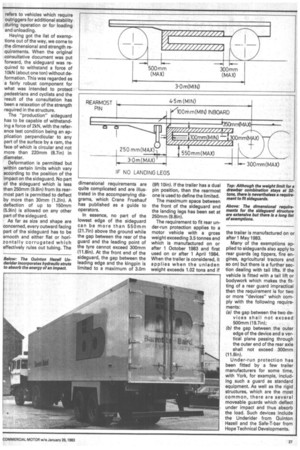

As far as size and shape are concerned, every outward facing part of the sideguard has to be smooth and either flat or horizontally corrugated which effectively rules out tubing. The dimensional requirements are quite complicated and are illustrated in the accompanying diagrams, which Crane Fruehauf has published as a guide to operators.

In essence, no part of the lowest edge of the sideguard can be more than 5 5 Omm (21.7in) above the ground while the gap between the rear of the guard and the leading point of the tyre cannot exceed 300mm (11.81n). At the front end of the sideguard, the gap between the leading edge and the kingpin is limited to a maximum of 3.0m (9ft 10in). If the trailer has a dual pin position, then the rearmost one is used to define the limited.

The maximum space between the front of the sideguard and the landing legs has been set at 250mm (9.81n).

The requirement to fit rear under-run protection applies to a motor vehicle with a gross weight exceeding 3.5 tonnes and which is manufactured on or after 1 October 1983 and first used on or after 1 April 1984. When the trailer is considered, it applies when the unladen weight exceeds 1.02 tons and if the trailer is manufactured on or after 1 May 1983, Many of the exemptions applied to sideguards also apply to rear guards (eg tippers, fire engines, agricultural tractors and so on) but there is a further section dealing with tail lifts. If the vehicle is fitted with a tail lift or bodywork which makes the fitting of a rear guard impractical then the requirement is for two or more "devices" which comply with the following requirements:

(a) the gap between the two devices shall not exceed 500mm (19.7in);

(b) the gap between the outer edge of the device and a vertical plane passing through the outer end of the rear axle shall not exceed 300mm (11.8in), Under-run protection has been fitted by a few trailer manufacturers for some time, with York, for example, including such a guard as standard equipment. As well as the rigid structures, which are the most common, there are several moveable guards which deflect under impact and thus absorb the load. Such devices include the Underider from Quinton Hazell and the Safe-T-bar from Hope Technical Developments.