Novel Features in Latest Chaseside Dumper

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

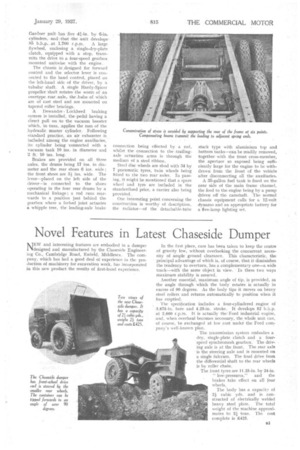

NEw and interesting features are embodied in a dumper designed and manufactured by the Chaseside Engineering Co., Cambridge Road, Enfield, Middlesex. The cornpany; which has had a good deal of experience in the production of machMery for excavation work, has incorporated in this new product the results of first-hand experience.

In the first place, care has beeu taken to keep the centre of gravity low, without overlooking the concurrent necessity of ample ground clearance. This characteristic, the principal advantage of which is of course, that it diminishes the tendency to overturn, has a complementary one—a wide track—with the same object in view. In these two ways maximum stability is assured.

Another essential, maximum angle of tip, is provided, as the angle through which the body rotates is actually in excess of 90 degrees. As the body tips it moves on heavy steel rollers and returns automatically to position when it has emptied.

The specification includes a four-cylindered engine of 3,875-in, bore and 4.25rin. stroke. It develops 52 b.h.p. at 2,600 r.p.m. It is actually the Ford industrial engine, and, when overhaul becomes necessary, the whole unit can, of course, be exchanged at low cost under the Ford company's well-known plan.

The transmission system embodies a dry, single-plate clutch and a fourspeed synchromesh gearbox: The driving axle is at the front. The rear axle is the steering axle and is mounted on a single fulcrum. The final drive from the differential shaft to the rear wheels is by roller chain.

The front tyres are 11.25-in. by 24-in. " low-pressures," and the brakes take effect on all four wheels.

The body has a capacity of 21 cubic yds. and is constructed of electrically welded heavy steel plate. The total weight of the machine approximates to 21 tons. The cost complete is £425.