COIL SPRINGS FOR VEHICLE SUSPENSION.

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

An Interesting Horstman System Described in Detail After a Short but Convincing Test.

AN ingenious suspension system employing coil springs was demonstrated to us recently on a llorstman saloon car, weighing about 16 ewt. It is claimed that the applicatiou of this design can be made to commercial-motor vehicles, private motorcars, aeroplane landing carriages and to a great many other wheeled vehicles where the load has to be insulated from surface undulations.

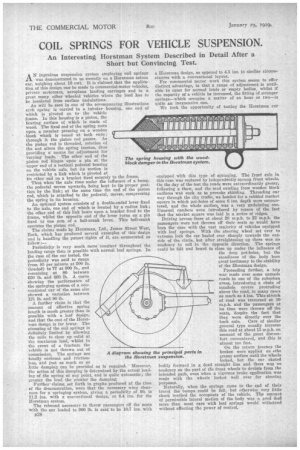

As will be seen in one of the accompanying illustrations each spring is carried in a tubular housing, one end of which is pivoted on to the vehicle frame. In this housing is a piston, the bearing surface of which is made of wood. The fixed end of the spring rests upon a member pressing on a wooden block which is coned at both ends ; through it the piston rod passes. As the piston rod is threaded, rotation of the nut 'alters the spring tension, thus providing a means for adjustment for varying loads. The other end of the piston rod hinges upon a pin at the upper end of a vertical pedestal bearing, on the vehicle axle, but its motion is restricted by a link which is pivoted at its other end on a bracket fixed securely to the frame.

Thus when the axle rises under the influence of a bump, the pedestal moves upwards, being kept in its proper position by the link; at the same time the end of the piston rod, which is attached to the pedestal, moves, compressing the spring in its housing.

An optional system consists of a double-ended lever fixed to the axle, one end of which is located by a radius link ; the other end of this link bears upon a bracket fixed to the frame, whilst the opposite end of the lever turns on a pin fixed to one arm of a bell-crank lever. This bell-crank operates the piston rod, The claims made by Horstman, Ltd., James Street West, Bath, which has produced several examples of this design and is handling the patent rights of it, are enumerated as follow:— Periodicity is very much more constant throughout the loading range than is possible with normal leaf springs, In the case of the car tested, the periodicity was said to range from 85 per minute at 500 lb. (loaded) to 77 at 900 lb., and remaining at 80 between 030 lb. and 800 lb. A curve • showing the performance of • the springing system of a conventional car of the same size showed a variation between 121 lb. and 90 lb.

A further claim is that the amount of effective spring length is much greater than is possible with a leaf design, and that the cost of the Horstman design is far lower. The stressing of the coil springs is definitely limited by allowing the coils to close up solid at the maximum load, whilst in the event of a fracture the vehicle is not thrown out of commission. The springs are totally enclosed end frictionless, and just as much or as little damping can be provided as is required. Moreover, the action of this damping is determined by the actual loading of the spring at any point, and is quite automatic ; the greater the load the greater the damping.

Further claims, set forth in graphs produced at the time of the demonstration, were that the necessary wing clearance for a springing system, giving a periodicity of SO, is 11.2 ins, with a conventional design, or 6.4 ins, for the Horstman system.

The rebound necessary to throw passengers off the seats with the car loaded to 900 lb. is said to be 10.7 ins. with B28 a Horstman design, as opposed to 4.3 ins. in similar circumstances with a conventional layout.

For conauercial motor work this system seems to offer distinct advantage, in that a range of adjustment is available to cater for normal loads or empty bodies, whilst if the capacity of a vehicle be increased, the fitting of stronger smings—which occupies a matter of an hour or two—is quite an inexuensive one.

We took the opportunity of testing the Horstman car

equipped with this type of springing. The front axle in this case was replaced by independently sprung front wheels. On the day of the test the roads were extraordinarily greasy, following a thaw, and the mud exuding from wooden block surfaces was such as to provoke skidding. Threading our way through the city traffic, we headed for a cobbled market square in which pot-holes of some 6 ins, depth were encountered, and the whole surface. was a very undulating one. Unusual cambers were introduced by reason of the fact that the market square was laid in a series of ridges.

Driving across these at about 20 m.p.h. to 22 m.p.h. the passengers were not thrown off their seats as would have been the case with the vast majority of vehicles equipped with leaf springs. With the steering wheel set over to extreme lock the car heeled over sharply towards the outside of the circle, but after straightening up there was no tendency to roll in the opposite direction. The springs could be felt and heard to close up under the influence of the deep pot-holes, but the steadiness of the body bore great testimony to the stability of the iforstman design.

Proceeding farther, a trip was made over some unmade roads in one of the suburban areas introducing a chain of manhole covers protruding above the road, in many cases as much as 4 ins. This stretch of road was traversed at 30 m.p.h. and the passengers at no time were thrown off the seats, despite the fact that they were directly over the

back axle. Cars of similar general type usually traverse this road at about 15 m.p.h. on account of the great discomfort encountered, and this is almost too fast.

On the return journey the brakes were 'applied on -the greasy surface until the wheels locked, but the car, skated bodily forward in a dead straight line and there was no tendency on the part of the front wheels to deviate from the intended path, even when a vigorous brake application was made with the wheels locked well over for steering purposes.

Naturally, when the springs came to the end of their travel the bumps could be felt, but otherwise very little shock reached the occupants of the vehicle. The amount of permissible lateral motion of the body was a good deal more than most cars with leaf springs would withstand without affecting the power of control.