INDIVISIBLE LOADS TO

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

THE CONTINENT...A. J. P. WILDING AM1MechE M1RTE

AS THE demand for transport through to the mainland of Europe has grown so have the problems in making direct deliveries of bulky and heavy indivisible loads to establishments on the Continent. There are limits naturally, on what can be carried in respect of both size and weight but these will change as more ferries develop and existing ones are converted. There is also controversy at present on the best way to arrange inter-Continental operation: should an operator send an attic outfit all the way or deliver the semi-trailer to the ferry and then have it picked up by a foreign tractive unit on the other side of the Channel?

The arguments for and against were submitted in evidence to the Licensing Authority in the recent M. & S. Shipping Ltd. application.

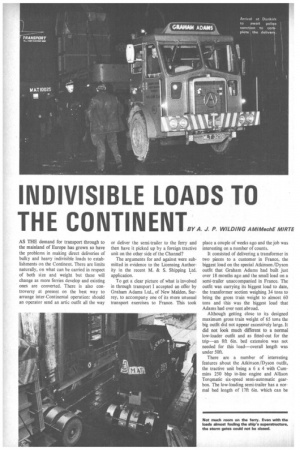

To get a clear picture of what is involved in through transport I accepted an offer by Graham Adams Ltd., of New Malden, Surrey, to accompany one of its more unusual transport exercises to France. This took place a couple of weeks ago and the job was interesting on a number of counts.

It consisted of delivering a transformer in two pieces to a customer in France, the biggest load on the special Atkinson/Dyson outfit that Graham Adams had built just over 18 months ago and the small load on a semi-trailer unaccompanied in France. The outfit was carrying its biggest load to date, the transformer section weighing 34 tons to bring the gross train weight to almost 60 tons and this was the biggest load that Adams had ever sent abroad.

Although getting close to its designed maximum gross train weight of 65 tons the big outfit did not appear excessively large. It did not look much different to a normal low-loader outfit and as fitted-out for the trip—an 8ft 6in. bed extension was not needed for this load—overall length was under 50ft.

There are a number of interesting features about the Atkinson /Dyson outfit, the tractive unit being a 6 x 4 with Cummins 250 bhp in-line engine and Allison Torqmatic six-speed semi-automatic gearbox. The low-loading semi-trailer has a normal bed length of 17ft 6in. which can be increased to 26ft with the extension and a removable swan-neck; in conjunction with knock-out rear oscillating axles the trailer bed can be laid on the ground to make loading easier.

Although not much out of the ordinary on width and length, load height was something of a problem—the top of the

• transformer being about 16ft from the ground. The load on the unaccompanied semi-trailer was to a similar height. It is difficult to find ferries capable of taking this type of load and none to Northern France can accommodate this height inside the vehicle deck. The only ferry that could take the two vehicles was the St. Germaine on the Dover-Dunkirk run. This had sufficient open deck aft of the covered vehicle deck to take the vehicles—although they only just fitted and the storm doors had to be left open for the crossing.

After loading up the Atkinson/Dyson outfit at Crawley, Sussex, the journey to Dover was uneventful.'the run was made in two stages with an overnight stop at Streatham and the total distance covered was 152 miles. compared with about 80 miles for the shortest possible route between the two towns. The second semi-trailer, with about 12 tons of transformer, was taken to Dover independently behind a Leyland Freightline Beaver. This had semi-automatic transmission which is considered a great advantage on heavy haulage by Graham Adams, managing director of the concern. So sure was he of the desirability of this feature that the Leyland was ordered at the Commercial Motor Show when the model was introduced and was only the sixth new Beaver built with semi-automatic transmission.

Largely due to hold-ups through fog on the way to Dover, the heavier outfit arrived later than expected—at 11.5 a.m. for the 11.25 boat. This fact did not have any effect on the sailing as vehicles were still being loaded and, in fact, the outfit was held back for at least half an hour in Western Dock for this reason. If late arrival had meant missing the boat, M.A.T. Transport, which was the forwarding agent for the loads, had the matter well in hand and the firm's Dover office had all the necessary contacts at the dock to sort things out.

It may have been better to have let the outfit get nearer to the dock for this last 100 yd proved the most difficult of the journey. The roadway to the ferry was never planned with current-length attics in mind as marks on the walls testify----it is time some alterations were made. Only excellent positioning of the outfit by the driver—Stan Ashby—and knowledgeable signals by Peter Spackman, his mate, managed to get it through the tight squeeze between the transit and Customs sheds. Parked vehicles did not make things any easier and it seemed at one time that it would be impossible for the outfit to get through. The tractor was right up against one wall and the offside trailer wheel was hard up against a wall on the other side of the gap.

The position was retrieved by placing baulks of timber next to the right-hand wall for the trailer wheels to ride over, tilt the oscillating axle and push the end of the trailer over. But the problems did not end there and before getting on the approach to the boat there was a nasty left-hand bend to make. This required two or three shunts with the trailer wheels on a sharp ramp. At one point with the wheels at an angle on this ramp there seemed every chance of the whole lot going over but by keeping the tractor moving the load was kept upright.

There were no similar difficulties at Dunkirk where unloading was straight into a wide open parking area. But that is as far as I went with the vehicles as authority had not come through to operate them in France and no idea of the delay could be obtained. Societe A.L.A., which acts as agents for M.A.T, at Dunkirk had applied for police permission in plenty of time but bad weather with snow had caused them to delay sanction.

Speaking to M. Duval, assistant manager of A.L.A., about the position I was told there would be no serious delay and that in normal circumstances both the outfit and the semi-trailer would have been cleared through Customs almost immediately as all the formalities had been taken care of. He said that there would he no difference at all between the treatment by Customs of accompanied and unaccompanied loads.

A.L.A. acts as agent for many companies including British Rail as well as M.A.T. and is also in shipping, owning one of the Dover-Dunkirk ferries. It became clear talking to M. Duval that the selection by an operator of an expert agent was more than half the battle in inter-Continental operation. He said that whilst a driver would find little difficulty at customs in travelling under T. I. R. Carnet he did not see how a driver on his own could get through the formalities. And as well as Customs and specialauthorization work, good agents will find return loads and smooth out any troubles_ An agent is needed at every border crossing and as well as the work mentioned, agents like A.L.A. can organize tractive units for unaccompanied semi-trailers. But it was clear that the best and often cheaper method was to operate complete outfits.

In the case of the Dover-Dunkirk ferry it works out at over 20 per cent cheaper to send a 42 ft outfit to France as against a 34 ft semi-trailer and the cost of hiring a tractive unit for the journey on the Continent can be much greater than using one's own vehicle. It is difficult to say what charges forwarding agents make but I gathered it can be as low as £3 to £5 a load for an outfit when the operator involved does a fair amount of business and no really involved work has to be undertaken.