) UP FOR ECONOMY

Page 47

Page 46

Page 48

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

t Shows iy while iyload : .p.g. at .h.

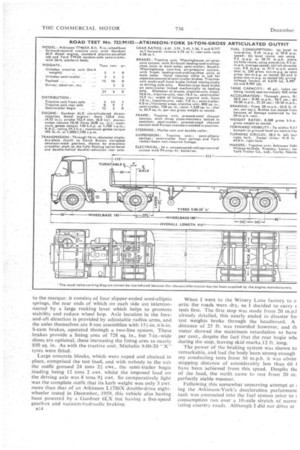

JUST as some people will only give of their best when they are working at top pressure, so there are some engines with similar characteristics. Perhaps the most outstanding of these is the Gardner 6LX, a well-run-in example of which was tested recently in an Atkinson-York 24-ton-gross articulated outfit and which defied all logic by giving 9.8 m.p.g. when driven flat out over 17 miles of motorway at an average speed of 37.4 m.p.h., but gave " only " 9.45 m.p.g. when driven steadily at just over 3.0 m.p.h. along a piece of fiat road.

This can only be taken to mean that the 6LX's famed fuel economy reaches its optimum well past the engine speed at which the manufacturers claim maximum torque is developed, and that "heavy footed" driving will actually reduce fuel costs providing the vehicle is suitably geared for the type of operation envisaged. That is to say, the operator's cruising-speed requirements should provide a guide as to the maximum road speed to be given by the gearing: a vehicle geared to give 45 m.p.h. maximum but cruised at 33/34 m.p.h. will not necessarily be as economical at this cruising speed as a similarly powered vehicle, the gearing of which gives a maximum of about 35 m.p.h. This again was shown during my test by figures taken over a level road when using and when not using overdrive: at just over 30 m.p.h. in each case there was a difference of only 0.15 m.p.g.

Outstanding as the fuel-consumption performance of the Gardner 6LX is, the virtue of this Atkinson-York combination by no means ends there. The complete outfit as tested had an unladen weight of only 8 tons 6+cwt., therefore its legal payload was as high as 15 tons 13+ cwt.—a particularly good figure for an outfit with tandem-axle semi-trailer. Combination of ' payload and fuel economy presents an obvious inference—this is the type-of outfit that any trunking operator who wishes to take maximum advantage of Britain's projected motorway network cannot afford to ignore. Drivers will second this choice whole-heartedly, for the Atkinson T746XA is a delightful vehicle to drive and to have to work in for long stretches.

As speeds and payloads rise, the safety aspect assumes B12 growing importance, and in this respect also the York is well to the fore—except for one detail whic not present undue difficulties to overcome. The of the combination tested was so good (witho dangerously fierce or unbalanced) that the first bra carried out from 20 m.p.h. almost tore the lu from the semi-trailer framing—an experience h enough to deter me from carrying out further brak With a suitably reinforced headboard mount Atkinson-York should be virtually as safe as a rii wheeler under most road conditions, whilst the stability of the outfit when driven fast over narro ing and undulating country roads inspired confiden The Atkinson T746XA tractive unit is one of a Atkinson four-wheelers which includes maximum load carriers and 16-, 22and 28-ton-gross tracti Gardner 4LW, 5LW, 6LW and 6LX diesel eni available, and there is a wide choice of gearboxes, i components of David Brown or German Z.F. man in each case with six forward speeds and either . overdrive top gears. Tractive units with the less powerful engines have overhead-worm axles, but 6LX-engined chassis are equipped with double-reduction axles, with spiral-bevel primary gearing combined with double-helical-spur secondary reductions. The standard ratio in these fully floating axles is 6.28 to 1, but there are alternative ratios of 5.2, 7.01 and 7.94 to 1. Atkinson's production flexibility provides a similar range of specification options with regard to the braking system: the Kirkstall cam-operated brakes can be specified with either vacuum-hydraulic or straight airpressure actuation, 16-in.-diameter front and 165-in.diameter rear brakes being employed in all cases, the total frictional area being 800 sq. in.

The Atkinson tractive unit's chassis frame is as straightforward as they come, consisting of parallel, constant-depth side members with three gusseted cross-members bolted in place. The side members are pressings, with 3-in.-wide flanges and a depth of 8+ in. The simple frame layout facilitates the provision of leftor right-hand drive and also the mounting of differing makes of semi-trailer coupling gear.

The front axle assembly is of conventional form, the king pins being carried in taper-roller bearings. Marles cam and double roller steering gear is standard, and there is no option of power steering, this equipment being unnecessary in any case. Michelin 9.00-20 "X " tyre equipment is standard, but export models have 11.00-20 (12-ply) tyres. Optional chassis equipment includes front and rear towing jaws, power take-offs and a chromium-plated front bumper bar. The standard cab is a composite assembly, with plastics panels on a timber frame, but there is also a steelframed plastics-panelled cab: the standard de-luxe cab was fitted to the test vehicle.

The semi-trailer provided for these tests was a York TW2A tandem-axle model, a praiseworthy feature of which was its low weight---3 tons 51cwt. The 26-ft. platform body had a 1-in.-thick hardwood floor, with longitudinal planking, and the main framing members were h-in, hightensile-steel pressings, with a maximum depth of 10 in. and 31-in. flanges, the complete framing assembly being welded together.

Bogie suspension of this design of semi-trailer is peculiar nt3 to the marque; it consists of four slipper-ended semi-elliptic springs, the rear ends of which on each side are interconnected by a large rocking lever which helps to promote stability and reduce wheel hop. Axle location in the foreand-aft direction is provided by adjustable radius arms, and the axles themselves are 8-ton assemblies with I51-in. X 6-in. S-cam brakes, operated through a two-line system. These brakes provide a lining area of 728 sq. in., but 7-in.-wide shoes are optional, these increasing the lining area to nearly 850 sq. in. As with the tractive unit, Michelin 9.00-20 X" tyres were fitted.

Large concrete blocks, which were roped and chained in place, comprised the test load, and with nobody in the cab the outfit grossed 24 tons 21 cwt., the semi-trailer bogie loading being 12 tons 2 cwt. whilst the imposed load on the driving axle was 8 tons 92, cwt. So comparatively light was the complete outfit that its kerb weight was only 3 cwt. more than that of an Atkinson L1786X double-drive eightwheeler tested in December,..] 959. this vehicle also having been powered by a Gardner 6LX but having a five-speed gearbox and vacuum-hydraulic braking. When I went to the Winery Lane factory to c artic the roads were dry, so I decided to carry ( tests first. The first stop was made from 20 m.p.I already detailed, this nearly ended in disaster he' test weights broke through the headboard. A distance of 25 ft. was recorded however, and th meter showed the maximum retardation to have per cent., despite the fact that the rear bogie whE during the stop, leaving skid marks.12 ft. long.

The power of the braking system was shown to remarkable, and had the body been strong enough my conducting tests from 30 m.p.h. it was obvio stopping distance of considerably less than 60 have been achieved from this speed. Despite thc of the load, the outfit came to rest from 20 m. perfectly stable manner.

Following this somewhat unnerving attempt at I ing the Atkinson-York's deceleration performanc tank was connected into the fuel system prior to consumption run over a 10-mile stretch of nano. lating country roads. Although I did not drive at

! course was completed at an average speed of a., whilst the tank indicated the consumption rate !en 9.3 m.p.g., which is as good a figure as anyone ect over as severe a route as this, the more so as the distance had to be completed in direct drive m overdrive.

us the outfit was taken on to a dual-carriageway the Preston-Southport road, the 5.9-mile circuit lost completely flat. Two tests were made over e, one treating the vehicle as having a direct-tOp and the other making use of overdrive whenever In view of the engine-economy characteristics ealt with, it is not altogether surprising that there Ile difference between the two fuel figures: both made while cruising at about 32 m.p.h., and this aning almost on the governor during the directs, but keeping the engine at about two-thirds speed when using overdrivesbear out the worth of the 11-throttle economy compared art-throttle performance.

ation tests‘ were conducted for the runs from a standstill m.p.h. second, third, fourth gears were employed, the speeds in these ratios being 21 and 33 m.p.h. respec

e speed in top gear being The standing-start acceIeraparticularly good in view of ason's none-too-high power: Equally satisfactory were .ear (direct drive) tests made 10 m.p.h. and 30 m.p.h., the -speed torque of the Gardner howing to the full when ig in this ratio up to 20 m.p.h., smoothness of the engine was ay the absence of engine and on roughness.

it-performance tests were made .d Hill, this being i-mile long, ierage gradient of 1 in 12. The slope was climbed bient temperature of 48° F. and the ascent took nutes 24 seconds, during the course of which time :rature of the coolant in the unblanked radiator its normal figure of 135° F. to a mere 142° F.— ..zoling is one of Gardner's essential requirements. nimum road speed noted during the ascent was Nhilst the lowest gear ratio employed was second, g been engaged for 1 minute 57 seconds. Whilst tio occasional, although slight, exhaust smoking ved. Taken generally, however, the climb was a table performance.

leek for the fade-resistance characteristics of the e artic. was coasted down the hill in neutral, a the footbrake alone to restrict the speed to This type of test is severe for any sort of vehicle, :tie grossing 24 tons, despite which a Tapley meter f 55 per cent, was obtained on the wet road at n of the hill when the brakes were applied hard m.p.h. The bogie wheels locked and hopped iring this stop (and the load shifted a bit more!) ehicle was generally quite stable as it came to he anti-fade performance can be considered quite drove the Atkinson-York back up the hill and on the steepest section, where the gradient is Used separately the semi-trailer brakes (applied by the hand-reaction valve in the cab) restrained the outfit from rolling hack down the hill, but the tractive unit and semi-trailer parking brakes would hold the vehicle by themselves when only helped on by the use of the foot-brake.

Several very smooth bottom-gear restarts were made on this gradient, but I found it not quite possible to get away from rest in second gear, malicious deliberate slipping of the clutch in an attempt to do this resulting in clouds of smoke pouring from the clutch housing.

The final test in the series proved to be a fitting climax, for the articulated outfit was subjected to a continuous full-throttle run over a 17-mile out-and-return circuit of the Preston By-pass motorway (M6). Despite the speed dropping to 18 m.p.h. on the hill north of the Samlesbury junction—fourth gear was used here—the circuit was completed in 27 minutes 10 seconds, overdrive having been engaged for a total time of 22 minutes 40 seconds. The total running time indicates an average speed of 37.4 m.p.h., whilst the use of 13.85 pints of fuel shows the consumption rate to have reached the remarkable figure of 9.8 m.p.g., the resulting timeload-mileage factor being 8,901—quite exceptional for a perfectly standard vehicle, even by motorway standards.

It is not hard to see, therefore, why the Atkinson 24-ton-gross tractive unit with Gardner 6LX engine has shown itself to be one of• the most popular models ever produced by Atkinson's, I and the results obtained during my test help to explain the increasing number of repeat orders that the manufacturers are getting for this vehicle. Drivers are full of praise for this " Atky " too, and this does not surprise me either.

Although devoid of gimmicks, the cab is a very comfortable one in which to work and the test outfit—which I drove for a total of 150 miles or so--was a pleasure to drive, not only because of the lightness of the controls but also because of the smooth riding of the unit and the generally low noise level. The steering has good castor characteristics and is light at all times, although certain road surfacescan generate slight wheel kicking at times, whilst motorway travel at 45 m.p.h. or so produced a certain amount of shimmy—probably because of front-wheel unbalance.

I found clutch actuation to be light, and, because the David Brown 657 gearbox is a sweet changer, use of the gearbox almost became a pleasure. I was relieved to find that the engine-cowl installation was not only effective against noise but was also sufficient to prevent heat reaching the driver from the exhaust manifold, which is on the right-hand side of the engine only a few inches away from the driver's left leg.

Detail points which I would like to see attended to are the size of the rear-view mirrors, which although quite deep are not really wide enough to give a full field of vision; replacement of the metal brakeand clutch-pedal pads• by less slippery rubber pads and rewiring of the instrument-panel lights, which at the moment can be switched on whether the side lights are on or not, and therefore provide no guide as to these lights being on. While on the subject of lights, I must say I was disappointed in the output of the headlamps, but discovered subsequently that these were only temporary items in lieu of the standard C.A.V. equipment which should have been fitted.