Overcoming Disadvantages of Gas Producers

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

PERHAPS the most serious disad vantages the to the use of gas producers on vehicles are those of irregular working when the vehicle is at a standstill, and an unsatisfactory get-away after the engine has been throttled down for some time. A simple little device intended to overcome these difficulties has just been patented by the Sagam Co., 32, Rue Hudry Courbevoie (Seine).

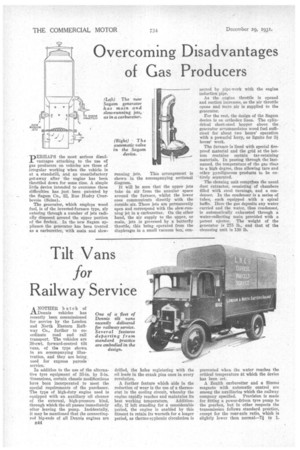

The generator, which employs wood fuel, is of the inverted-furnace type, air entering through a number of jets radially disposed around the upper portion of the firebox. In the new Sagam an_ pliance the generator has been treated as a carburetter, with main and slow

running jets. This arrangement is shown in the accompanying sectional diagram.

It will be seen that the upper jets take in air from the annular space around the furnace, whilst the lower ones communicate directly with the outside air. These jets are permanently open and correspond with the slow-running jet in a carburetter. On the other hand, the air supply to the upper, or main, jets is governed by a butterfly throttle, this being operated from the diaphragm in a small vacuum box; con

nected by pipc-work with the engine induction pipe.

As the engine throttle is opened and suction increases, so the air throttle opens and more air is supplied to the generator.

For the rest, the design of the Sagam device is on orthodox lines. The cylindrical sheet-steel hopper above the generator accommodates wood fuel sufficient for about two hours' operation with a powerful lorry, or lignite for 3* hours' work.

The furnace is lined with special fireproof material and the grid at the bottom contains certain tar-retaining materials. In passing through the lastnamed, the temperature of the gas rises to a high degree, thus allowing tars and other pyroligneous products to be entirely separated.

The cleaning unit comprises the usual dust extractor, consisting of chambers filled with steel turnings, and a condenser. In the condenser is a series of tubes, each equipped with a spiral bailie. Here the gas deposits any water carried and the water, thus condensed, is automatically exhausted through a water-collecting main provided with a patent ejector. The weight of the generator is 275 lb., and that of the cleansing unit is 130 lb.