HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best out of a Vehicle, to Secure Reliability and to Avoid Trouble.

CONTRIBUTIONS are .nvited for this page from fleet managers, drivers, garage foremen, and meclutuir.s, works staff and draturhtsmen, and will be paid for on a generous scale. Every system, make, and type of commercial motor vehicle is being dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle.

We give the solution of the trouble, because this may assist users of this and other makes of vehicle who may have experienced similar difficulties.

In the example in question occasional seizing occurred of the bush on the off-side rear wheel, apparently through lack of lubricant.

It was found on examination that the filler cap and tube fitted to the centre casing of the rear axle permitted the oil to reach only to the level of the centre line of the axle. This was quite effective while the vehicle Was running on level roads, but when it had to run over long distances on the near-side camber the lubricant drained away from the off-side bush, which, consequently, ran dry.

A cure of the trouble was effected by unscrewing the filler cap, fitting into its place a 14-in. gas nipple, above this an ordinary pipe coupling, and then the original filler cap. This enabled the axle to be filled rather higher than formerly and made all the difference to the lubrication.

In cases where the filler bracket is attached to a thin mental cover the extra weight of the parts fitted • may necessitate the addition of a small stay to the•filler.

662.—Strengthening Fabric Discs.

The tendency for the fabric type of universal joint to become soft and very dilapidated after a long period of use is well known to most drivers and mechanics, and the greatest care should be taken of a joint falling

into such a condition, because a breakage not only involves considerable delay, but will possibly constitute a danger if no emergency device for supporting the propeller shaft at the front end he available.

One of our contributors points out that the trouble can, to a great extent, be obviated by cutting a number of discs from 24-gauge sheet steel of good quality, slotting these radially, and drilling bolt holes to correspond with those in the fabric joints. These discs should be inserted between, and at each side of, the fabric laminations, so that the metal and fabric alternate. This method is said not to impair the universal action of the joint, whilst the tendency to sag and fray is entirely

removed. ,

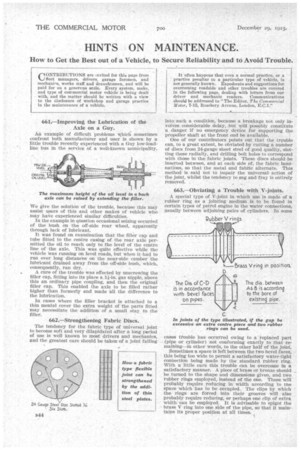

663.—Obviating a Trouble with V-joints.

A special type of V-joint in which use is made of a rubber ring as a jointing medium is to he found in certain types of petrol engine in the water connections, usually between adjoining pairs of cylinders. In some

cases tfouble has occurred owing to a. replaced part (pipe or cylinder) not conforming exactly to that remaining—in other words, to the other half of the joint.

Sometimes a space is left between the two bevel faces, this being too wide to permit a satisfactory water-tight connection being made by the standard rubber ring. With a little care this trouble can be overcome in a satisfactory manner A piece of brass or bronze should , be turned to the shape and dimensions given, and two rubber rings employed, instead of the one. These will probably require reducing in width according to me space which has to be occupied. The clips by which the rings are forced into their grooves will also probably require reducing, or perhaps one clip of extra width can be employed. It is advisable to spigot the brass V .ring into one side of the pipe, so that it main-tains its proper position at all times.