Rating and Plating

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

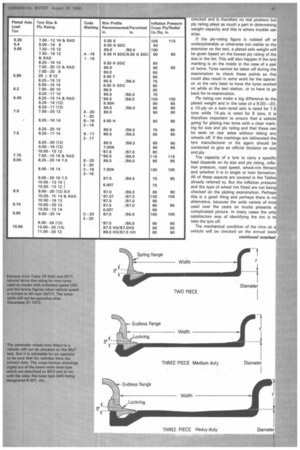

the first category is left open (the other two crossed bud Table 2B will be worked to for plating, if the second, it will be GP/1 and if the third, 2J. So it will be clear that question 16 is a very important one.

The "bonus" given by GP/1 may be worth having if an operator can be certain that 4-0 mph will never be exceeded. Many vehicles on the road cannot do more than this speed -at least when in gear-but there could be trouble if a vehicle with the speed restriction quoted on the plating certificate were stopped for speeding. Table GP/1 is applicable only up to December 81 1972 by which time it is no doubt presumed vehicles will be brought into line with the standards of 20.

In any event the extra weight allowed is relatively small. It amounts to 0.6 tons only on an axle with twin 8.25 or 9.00-20 tyres, for example, and in the case of single tyres it is mainly applied to small-diameter types with the largest 20m. tyre quoted a 7.50 section.

It is most important to complete question 16 correctly, paying particular attention to the words' at any time-. This means exactly what it says and I have heard of a number of cases where an operator has left open part 3 because "most of the work was local and therefore within 40 mph limits" only to find that the plating certificate limits the vehicle for all time to a 25 mile radius and prevents the odd journey beyond this distance unless the vehicle is put forward for replating. This is all the more disturbing when the vehicle is over tyred even for use "without restriction".

It is also very important when sending a vehicle for test and plating that the tyre size and ply rating marks are clearly visible and able to be seen by the examiner. Size can be checked and is therefore no real problem but ply rating plays as much a part in determining weight capacity and this is where trouble can arise.

If the ply-rating figure is rubbed off or undecipherable or otherwise not visible to the examiner on the test, a plated axle weight will be given based on the lowest ply rating of the size in the list. This will also happen if the tyre marking is on the inside i.n the case of a pair of twins. Tyres cannot be taken off during the • examination to check these points so this could also result in extra work for the operator: at the very least to have the tyres worked on while at the test station, or to have to go back for re-examination.

Ply rating can make a big difference to the plated weight and in the case of a 9.00-20, a 10-ply on a twin-tyred axle is rated for 7.5 tons while 14-ply is rated for 9 tons. It is therefore important to ensure that a vehicle going for plating has tyres with a clear marking for size and ply rating and that these can be seen on rear axles without taking any wheels off. If the markings are obliterated the tyre manufacturer or his agent should be contacted to give an official decision on size and ply.

The capacity of a tyre to carry a specific load depends on its size and ply rating, inflation pressure, road speed, wheel-rim fitment and whether it is in single or twin formation. All of these aspects are covered in the Tables already referred to. But the inflation pressure and the type of wheel rim fitted are not being checked on the plating examination. Perhaps this is a good thing and perhaps there is n alternative, because the wide variety of rim used over the years on trucks presents a complicated picture. In many cases the onl satisfactory way of identifying the rim is t take the tyre off.

The mechanical condition of the rims on a vehicle will be checked on the annual tes continued overleaf and it would seem obvious that a rim which is obviously the wrong size or type for the tyre may be turned down, particularly if the examiner knows something about the subject and can identify individual types.

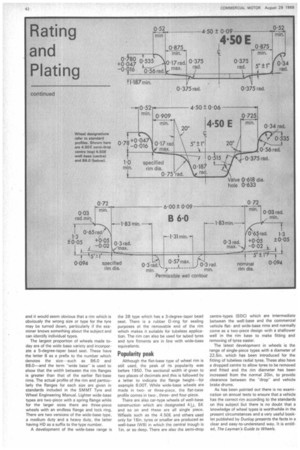

The largest proportion of wheels made today are of the wide-base variety and incorporate a 5-degree-taper bead seat. These have the letter B as a prefix to the number which denotes the size-such as B6.0 and 88.0-and the term "wide base" is used to show that the width between the rim flanges is greater than that of the earlier flat-base rims. The actual profile of the rim and particularly the flanges for each size are given in standards included in the SMMT Tyre and Wheel Engineering Manual. Lighter wide-base types are two-piece with a spring flange while for the larger sixes there are three-piece wheels with an endless flange and lock ring. There are two versions of the wide-base type, a medium duty and a heavy duty, the latter having HD as a suffix to the type number.

A development of the wide-base range is the 3B type which has a 3-degree-taper bead seat. There is a rubber 0-ring for sealing purposes at the removable end of the rim which makes it suitable for tubeless application. The rim can also be used for tubed tyres and tyre fitments are in line with wide-base equivalents,

Popularity peak

Although the flat-base type of wheel rim is still used, the peak of its popularity was before 1950. The sectional width iggiven to two places of decimals and this is followed by a letter to indicate the flange height-for example 6.00T. While wide-base wheels are made in twoor three-piece, the flat-base profile comes in two-, threeand four-piece.

There are also car-type wheels of well-base construction which are designated 44j, 5K and so on and these are all single piece. Wheels such as the 4.50E and others used only for 16in. tyres or smaller are produced as well-base IVV131 in which the central trough is 1in. or so deep. There are also the semi-drop centre-types (SDC) which are intermediate between the well-base and the commercial vehicle flatand wide-base rims and normally come as a two-piece design with a shallower well in the rim base to make fitting and removing of tyres easier.

The latest development in wheels is the range of single-piece types with a diameter of 22.5in. which has been introduced for the fitting of tubeless radial tyres. These also have a dropped centre to allow tyres to be removed and fitted and the rim diameter has been increased from the normal 20in, to provide clearance between the "drop" and vehicle brake drums.

As has been pointed out there is no examination on annual tests to ensure that a vehicle has the correct rim according to the standards on this subject but there is no doubt that a knowledge of wheel types is worthwhile in the present circumstances and a very useful booklet published by Dunlop presents the facts in a clear and easy-to-understand Way. It is entitled, The Layman's Guide to Wheels.