40 m.p.h. in 50 Secs. with a

Page 42

Page 43

Page 44

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

Six-wheeler

Laurence J. Cotton, M.I.R.T.E.

IT is uncommon to find a fully laden six-wheeler that can challenge and overtake the high-performance light four-wheelers on hills or in flat country, but such was my experience ween testing the latest Thornyeroft overseas chassis. Running at a gross weight of 20 tons, but powered by an 11.3-litre petrol engine, it was able to climb main road gradients mostly on top, or "eleventh," gear and on level ground 50 m.p.h. was a comfortable cruising speed.

The model tested was a successor to the former South African Railways chassis, with improvements to yield better performance. Modifications to the engine have 'raised its output to 170 b.h.p. at 2,200 r.p.m. The transmission system includes a four-speed main gearbox used in conjunction with a three-speed auxiliary unit. South African Railways have ordered 190 of these chassis, some of which will have a new 11.3-litre oil engine.

Engine performance has been improved by using a new design of intake manifold and by opening out the ports in the cylinder head. In addition to raising the power at the top end of the speed range, these measures have reduced pinking on full throttle or at the lower end of the range. The maximum torque of 520 lb.-ft. has not been affected by these modifications.

The Thornyeroft 11.3-litre petrol engine has separate cylinder block and crankcase castings, but the long studs employed for attachment are extended through the crankcase to provide support for the main-bearing caps and keeper plates at the lower end. Dry flangeless cylinder liners are fitted. The overhead valve gear has a chain-and-sprocket-driven camshaft in the cylinder block, operating the valves by push-rods and rockers.

As the chassis has been built for operation in warm climates, special attention has been paid to engine cooling. The water system has a total capacity of 16 gallons and the six-bladed 24-in, fan, positively driven through a friction clutch, revolves in a close-fitting shroud. The oil sump is designed and ribbed for maximum cooling, and a large external oil filter is fitted below it.

A build-up of hot-air pockets under the bonnet is prevented by using a recessed bulkhead with vents to expel the air between the cab and body. Air for combustion is drawn through an oil-bath cleaner, fitted with twin heads, mounted on the near side of the cab. The petrol pump has been moved forward to the side of the timing case, where it is in a better position to be cooled by the main air stream.

The new four-speed gearbox is of the Antar type, having a cast-iron housing and dog-clutch engagement of the straight-toothed gears. This box is attached as a unit with the engine and clutch, but the auxiliary box, which is also of Antar pattern, is remotely mounted in the frame. The auxiliary box has a light-alloy case and the ratios are arranged for step-down, direct and overdrive. Engagement is again through dog clutches, so that in normal driving the auxiliary can be used to provide intermediate ratios between the gears of the main gearbox.

In South Africa the Thornycrofts are required to operate over arterial and earth roads, therefore the single-spring bogie is arranged for a 12-in, difference in wheel levels diagonally and a 6-in, variation in axle levels. The suspension system includes an inverted semielliptic spring at each side, attached to the axles through large ball trunnions to prevent twist being transmitted to the main leaf. Driving and braking torque is controlled by I-section radius arms coupled to the centre crosS-tube of the bogie by a rubber'bushed link. This link is arranged so that angular and axial deflection of the rubber bush is equal to half the axle movement.

There has been a modification in the Clayton Dewandre compressedair braking system to include a dual valve which operates the front and rear, brakes independently. -This automatically isolates the front or rear air lines should a pipe become frac

(5) The Thornycroft engine tured. The brake shoes are cam-operated has twin carburetters and by direct linkage to the air cylinders. A

hot pockets of air are pretwin-cylindered engine-driven compressor vented from forming under

the bonnet by the vents in supplies air through an unloader valve to the rear panel. The petrol the two reservoirs. Formerly a single pump is now located at the reservoir was employed. front of the enginehree-speed ior better Another change 'since the original

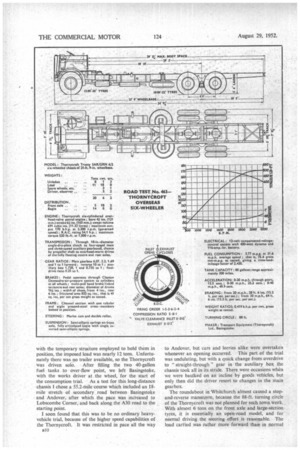

cooling. (6) The t

auxiliary gearbox is independesign was evolved is the employment of dently mounted in the frame. twin wheels on the centre and rear axles.

Provision is made to carry two spare wheels, one equipped with a 13.00-20-in. tyre for the front and the other with a 10.00-22-in, cover for the bogie axles. The carriers have built-in winches which can be operated by the wheel-nut spanner.

The chassis is extremely robust, having a frame with side members 11 ins. deep, and generous-sized bolted cross-members. All the pressedsteel cross-menters are flitch-plated at the ends for more rigid.attach

ment to the sifle-member flanges. An ample margin of safety is reflected in the .entire design of the chassis and the model tested, of 21-ft, 9-in, wheelbase, weighed just over 8 tons unladen. In South Africa the vehicle will carry a robust body and 10-ton payload in addition to hauling a trailer and load totalling 14 tons. There is also a chassis frame of 18-ft. 4-in, wheelbase, but the load rating is the same.

For my test the chassis carried 11 one-ton blocks of concrete, and a9 with the temporary struCture employed to hold them in position, the imposed load was nearly 12 tons. Unfortunately there was no trailer available, so the Thornycroft was driven solo. After filling the two 40-gallon fuel tanks to over-flow point, we left Basingstoke, with the works driver at the wheel, for the start of the consumption trial. As a test for this long-distance chassis I chose a 55.2-mile course which included an 18mile stretch of secondary road between Basingstoke and Andover, after which the pace was increased to Lobscombe Corner, and back along the A30 road to the starting point.

I soon found that this was to be no ordinary heavy. vehicle trial, because of the higher speed capabilities of the Thornycroft. It was restricted in pace all the way I

to Andover, but cars and lorries alike were overtaken whenever an opening occurred. This part of the trial was undulating, but with a quick change from overdrive to " straight-through " gear in the auxiliary box the chassis took all in its stride. There were occasions when we were baulked on an incline by goods vehicles, but only then did the driver resort to changes in the main gearbox.

The roundabout in 'Whitchurch almost caused a stopand-reverse manceuvre, because the 88-ft. turning circle of the Thornycroft was not planned for such town work. With almost 6 tons on the front axle and large-section tyres, it is essentially an open-road model, and for normal driving the steering effort ,is reasonable. The load carried was rather more forward than in normal

service, because with correct weight distribution only 51 tons is carried on the front axle.

After 18 miles the average speed was only 27 m.p.h., but once clear of Andover we were frequently cruising at 50 m.p.h., with the tachometer indicating an engine speed of 2,200 r.p.m. There were opportunities for a brief burst of speed after turning on to the main West Country road at Lobscombe Corner and I had to brace myself against the wind as we accelerated to a mile a minute. I ventured a "crash stop" at high speed and the brakes behaved perfectly, pulling the 20-toh vehicle up sharply on a straight course.

There were delays in Stockbridge, but to give some impression of the Thornycroft's abilities, 37.2 miles were covered in 65 minutes, including all delays and stops, which corresponds to an average speed of just over 34 m.p.h. Many car owners would like to achieve such a performance over a similar route.

High speed is attained at the cost of economy, and just over 15i gallons of petrol were used in driving round the circuit, giving a consumption rate of 31 m.p.g. The chassis tested had a low axle ratio of 8.25 to 1, because it will have to pull a trailer up hills 40 miles long, but there are ratios of 7.25 and 6.75 to 1, which would have afforded more economical performance in a solo• machine over the test course. With a trailer attaehed, the six-wheeler is giving a fuel return of 21-3 m.p.g. in operation.

When refuelling, I noticed that the tyres employed were retreaded by Auto Tyre Services, Ltd., Basingstoke. They withstood some rough treatment daring the day, as they always are, being used as' a slave set for test purposes only.

Little Pinking

After the exhilarating fuel-consumption test, the short performance trials were comparatively tame. For the hill-climbing test the chassis was headed towards Farleigh in an attempt to reduce the previous time of 4 mins. 38 secs, recorded for the overseas six-wheeler. Here the value of the 12-speed transmission and low-ratio axle was more apparent, and the second-gear direct-drive was ideal for the 1 in 8.4 section without over-speeding the engine. I noticed that the changes in the induction manifold and ports had almost eliminated pinking when pulling at low speed, and a higher gear was employed when negotiating the final stage of the climb. A quarter of a minute was saved and over the 1.4-mile observed distance, the average speed of 19.1 m.p.h. was 1 m.p.h.. faster than that of the earlier overseas six-wheeler.

With an ambient reading of 82 degrees F., water temperatures had remained low throughout the day. During the consumption trial the top tank remained constant at 145 degrees F. and there was only a 3-degree rise when climbing Farleigh Hill. The results indicated that the radiator water would be well below boiling point in the tropics. Sitting behind the bulkhead panel I was conscious of the flow of hot air from under the bonnet, the temperature of this current being 35 degrees above day reading.

Good Brakes

The road surface was hot when braking efficiency was measured and the bogie wheels locked on every test. In prototype testing the brakes were considered too effective and likely to cause premature damage to the body, so the line pressure on the front units had been reduced. Even so, to stop 20 tons from 30 m.p.h. in 65 ft. is effective braking, and such was the consistent stopping distance recorded. In normal driving, with full load, steady pressure on the pedal produced smooth deceleration, and this progressive braking was retained when making the emergency stops.

With direct drive engaged in the auxiliary box, the new six-wheeler was considerably faster in acceleration than its predecessor, which admittedly was equipped with a higher-ratio final drive. It took 25.2 secs., as an average of several runs, to each 30 m.p.h. and with a quick but silent change into overdrive, the 40 m.p.h. mark was passed in under 50 secs. This is unusual acceleration for a six-wheeler, but is the performance demanded by overseas operators.

As an alternative to the petrol engine, a new 11.3-litre direct-injection oil engine has'been. produced. It is interchangeable-with the 11.3-litre petrol engine in the overseas six-wheeler. .