Bristol Eight wheeler is Born

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

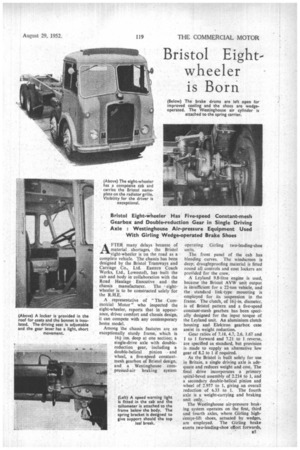

FTER many delays because of material shortages, the Bristol eight-wheeler is on the road as a complete vehicle. The chassis has been designed by the Bristol Tramways and Carriage Co., Ltd. Eastern Coach Works, Ltd., Lowestoft, has built the cab and body in collaboration with the Road Haulage Executive and the chassis manufacturer. The eightwheeler is to be constructed solely for the R.H.E.

A representative of "The Commercial Motor" who inspected the eight-wheeler, reports that in appearance, driver comfort and chassis design, it can compete with any contemporary home model.

Among The chassis features are an exceptionally sturdy frame, which is 16i ins, deep at one section; a single-drive axle with doublereduction gear, including a double-helical pinion and wheel, a five-speed constantmesh gearbox of Bristol design, and a Westinghouse compressed-air braking system operating Girling two-leading-shoe units.

The front panel of the cab has blending curves. The windscreen is deep; draughtproofing material is fitted round all controls and coat lockers are provided for the crew, A Leyland 9.8-litre engine is used, because the Bristol AVW unit output is insufficient for a 22-ton vehicle, and the standard link-type mounting is employed for its suspension in the frame. The clutch, of 161-in. diameter. is of Bristol pattern and a five-speed constant-mesh gearbox has been specially designed for the input torque of the Leyland unit. An aluminium clutch housing and Elektron gearbox case assist in weight reduction.

Gear ratios of 7.18, 4.7, 2.6. 1.67 and 1 to 1 forward and 7.21 to I reverse, are specified as standard, but provision is made to supply an alternative low gear of 8.2 to 1 if required.

As the Bristol is built solely for use in Britain, a single driving axle is adequate and reduces weight and cost. The final drive incorporates a primary spiral-bevel assembly of 2.214 to 1, and a secondary double-helical pinion and wheel of 2.957 to 1, giving an overall reduction of 6.33 to 1. The fourth axle is a weight-carrying and braking unit only.

The Westinghouse air-pressure braking system operates on the first, third and fourth axles, where Girling highcentre-lift shoes, actuated by wedges, are employed. The Girling brake exerts two-leading-shoe effort forwards, as well as having single-leading-shoe characteristics to assist in holding the lorry. firmly when pointing up a gradient. • Drums of 151-ia. diameter are fitted to the three braking axles, and the shoes are 4+ ins: wide on the leading axle and 7 ins, wide on the third and fourth axles. The total frictional area is 854 sq. ins.

The frame is exceptional, tapering in depth from 161-in. at the rear of, the second axle to 10+ ins, at its nominal section. There are eight bolted pressedsteel cross-members, the one at the rear being of boxed section and braced by an A-bracket to carry the Neates towing jaw which is provided for hauling a 7-ton trailer.

The frame is wide, with the road springs supported below the main longitudinals. Conventional overhead semi-elliptic springs are used, but the brackets supporting the first and second springs are composite and the balancebeams, between the third and fourth springs, turn on needle-roller hearings and have an integral oil reservoir. Silentbloc bushes are u,sed in the eyes of the springs on the front and second axles, whilst the driving and trailingaxle springs have chromium-plated pins with normal lubrication.

Instruments comprise only oil and air-pressure gauges and a 20 m.p.h. speed-indicator light operated from a Geecen pilot unit. A milometer head is attached to the frame below the body. Thereris no speedometer.

71 Tons Running Weight Equipped with -36-in. by 8-in, dualmarked tyres all round, the Bristol weighs 7 tons 10 .cwt. in running condition, with spare wheel and carrier and flat platform body 24 ft. 7 ins, long and 7 ft. 4+ ins. wide. Dry weight of the vehicle in licensing condition is 7 tons 41 cwt.

The composite-construction cab includes a grille over the Bristol radiator. This has been designed specially for the eight-wheeler, and has 52 Clayton Still tubes and a frontal area of 644 sq. ins. A blind is provided and the grille is arranged so that it can be raised to

cover the radiator in four stages, but no thermometer is fitted. The cab has an ash frame covered With 18 s.w.g. aluminium panels, and is mounted on rubber pads at the front and on Silent' bloc spigot brackets at the rear. Steel panels are employed inside the doors and at the corners.

Lockers are provided in the cab roof, above the bonnet, for coats and other personal equipment of the crew, and there are glove boxes formed in the front panel. The degree of visibility from the driving seat is exceptional, the windscreen being 2 ft. 4 ins, deep at the outer edge. The centre and corner pillars are narrow.

Refinements in the cab include a Widney adjustable driving seat, hit-andmiss vents in the front panel and shutter vents in the side quarter panels, two remote-type windscreen wipers, insulation of the bonnet and draught-proofing where the controls pass through the floor.

The body floor is made of 11-in. hardwood on main bearers of 5-in. by 2-in. section.