For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN SHILLINGS is awarded each week to the sender of the best letter which we publish on this page; all others are paid for at the rate of a penny a line, with an allowance for photographs. All notes are edited before being published. Mention your employer's name, in confidence, as evidence of good faith. Address. D., 31. and F.. "The Commercial Motor," 7-15, Rosebery Avenue, London, E.G. 1.

Lamps Alight.

On Saturday, the 31st August, light your lamps at l 8. g in London, 9.8 in Edinburgh_, 8.30 in Newcastle, 8.33 in Liverpool, 8.27 in Birmingham, 8.28-in Bristol, and 9.19 in Dublin.

Oil Leaking Along Valve Tappets: a Cure.

The sender of the following communication has been awarded the 10s. prize this week, [1891] " A.E.K." (Derby) writes :—" There are very few petrol engines which have not suffered at some time or other from leakage of oil along the valve tappets. Generally, the remedy prescribed is new tappets, new guides or both. In the course of my experience as mechanic I have had several examples of this kind of thing with which to deal, in most cases with the exasperating result that, after having fitted complete a new set of tappets and guides, all perfect both as regards workmanship, fit and finish, the old fault would crop up again after a few weeks or so. "Various means of countering the trouble have been suggested from time to time. I think I have tried most of them. On one occasion, on examination of the tappets and guides, I found the clearance between them to be practically negligible, and it occurred lo me that air pressure inside the crankcase might be playing a leading part in forcing the oil up the guides. I therefore considerably increased the size of the crankcase vents, without, however, stopping the leakage. A careful inspection of the lubrication system was made to see if any excessive amount of oil was being thrown about inside the crankcase chamber. Everything inside there was, however, in good order, and as the oil pressure on the bearings was very low, it was clear that no reduction in the pressure, with a view to obtaining a, reduction of the pressure in this manner, was advisable.

"It was obvious that any modification in the design would have to be effected in the region on the tappets and guides themselves. The guides were constructed of bronze. They were circular in form, tapering slightly upwards. The walls were very thin, evidently with the view to obviating the waste of useful material. They were held in place in pairs by retaining dogs. An examination of the valve gear revealed the fact that the guides could he made II in. longer without interfering with the effective working. I therefore made a new set, this time of cast iron, and longer than the existing ones by the amount stated. Owing to the increased length, the wear was

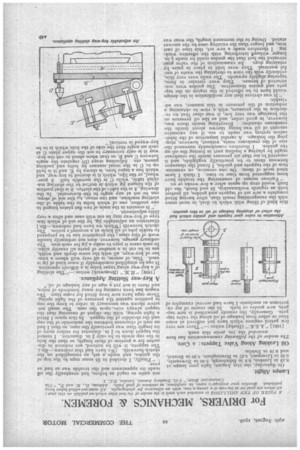

not quite so rapid as before, but eventually the oil made its appearance and the trouble was as bad as ever. "Finally, I decided to fit some caps to the top of the guides, and made as et, as exemplified on the sketch. herewith. (We have had this redrawn.—En.). The tappets, it will be noticed, are reduced in diameter for a portion of their length, so that the hole in the cap needs to be only I in. diameter. I turned the tappet down to ;1 in. diameter for rather more of its length than was previously the case, so that I had an inch of clearance between the underside of the cap and the shoulder of the tappet. In this space I fitted a light spring, with the .ebject of ensuring that the tappet always pore,. upon the cam. The small setscrew shown was necessary in order to keep the cap in position against the pressure of the light spring. These caps have now been fitted for some time. The wagon has been running for many hundreds of miles, and there is not yet a sign of any leakage of oil."

A Key-way Slotting Appliance.

[1892] " H.M." (Bromwich) writes :—" The slotting of a key-way along taper holes is a. difficult operation_ It can be simplified considerably if some kind of jig is used. This, of course, is all very well where a number of key-ways, all with the same depth and width, are to be cut in a, number of parts all exactly alike. In such cases it pays to make a jig for each size. The ordinary garage, however, does not ordinarily handle work of this class; the proprietor has to be prepared to tackle jobs of all kinds at a moment's notice. The sketch herewith [Which we have had redrawn.—En.] illustrates an adjustable jig, by the aid of which this type of key-way may be cut with ease and after a very little adjustment. ,." It consists in the main of two fiat plates hinged to one another, one of which bolts to the table of ,the slotting machine, and cne other, by the aid of stops' can be set at any angle to the horizontal. In the drawingA is the table of the slotter. B is that portion of the hinged jig which As bolted to the slotting ma-chine table, while C is the movable half. A gearwheel, or the like, which it is desired to key-way, and which has a taper bore, is shown by E, and it is held on to C in the usual manner by bolts and packing pieces, etc. Adjusting stops (D) regulate the angle between C and B. so that -when about to cut the keyway it is only necessary to set the upper plate C at such an angle that the side of the bole which is to be key-wayed is vertical."