• COAL-GAS PROGRESS.

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

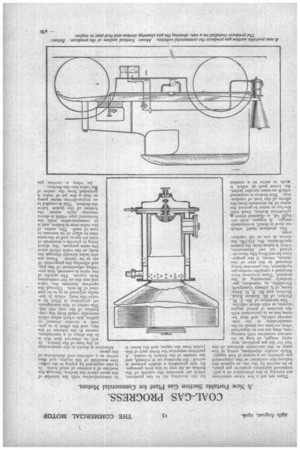

A New Portable Suction Gas Plant for Commercial Motors.

There are not a few whose attentions are turning to the alternative of a self

contained miniature producer gas plant, to be carried by the car, as against the balloon-like coatainer or the compressed gas cylinder, as a source of fuel supply. While sundry objections, owingiñ the main to the inevitable dirtiness of the feel for the gas producer, may carry weight, so long as we concern ourselves with touring cars, they are not so important when we turn our minds to the consideration of the commercial vehicle, and they become less so in connection with the heaviest of petrol engine chassis, or with steam vehicles. The invention of Mr. J. W. Parker, of 22, Radnor Road, Harrow, and Mr. E. G. Abrahams, of 5, Albany Courtyard,

' Piccadilly, is, therefore, particularly interesting at the moment. These inventors have designed a complete auction gas equipment, the generator being disposed at the rear of the chassis, where, if the proportions be anything like those depicted on our illustration, which is taken from the patent specification, No. 116,746, the device. is not. at all cumbersome.

The producer itself, which we show in detail, is extremely simple. A hopper, with airtight lid, is disposed above a. cylindrical firebox, lined with fireclay in order to protect the metal of its strocture from the effects of the heat of combus

tion. This firebox is contained within an outer circular jacket, " the lower part of which is nude to serve as a conduit

in communication with the interior of the space above the firebox' through the medium of a number of small holes. It is also connected by piping to the induction manifold of the engine, and thus • serves as a collector and distributer of the gases.

Attention is drawn to the construction at the base of the firebox. It will be observed that this is in the shape of a hemisphere, convex to the interior of the box, and the effeet is to provide a circular channel or gutter, into which ashes which naturally result from the combustion of the coal will fall. The centre of this hemispherical projection is filled by a valve-like body which is normally adjusted so as to be just clear of its seat. Through the aperture between the valve and seat the air for combustion finds ingress. The spindle of the valve is screwed, thin providing adjustment of the gap, and allowing the proportion of air to. be varied. There are also holes directly through the body of the valve which serve the same purpose, the object being to provide a minimum of inlet air space, and at the same time to allow of its increase in case of need. The centre of the valve stem is hollow, and is in communication with the horizontal pipe which is shown running right across the bottom of the jacket below the firebox. This' is coupled to an engine-driven water pump i so that a fine jet of water s projected from the centre of the valve into the firebox.

As when a suction gas

furnace is first lit, there is •a certain amount of smoke produced, it is necessary to provide some means. for getting rid of this. The inventors have incorporated a small cock in the gas pipe, which is placed near to the induction

manifold, and in the beginning, when the fire is first lit, this cock may be left open: When the engine is actually running, this tap may still remain open to a greater or less extent, providing the necessary additional air to form an ex plosive mixthre for the gas drawn from. the producer. Provision for cleaning out the producer is anade, an air-tight door giving access to the interior of the firebox, while a small valve allows of dust being removed from its interior.