THE POWER GAME:A PTO FOR EVERY TRANSMISSION

Page 161

Page 163

If you've noticed an error in this article please click here to report it so we can fix it.

No tipper can operate without a pto or combined pto/pump. It's a precision piece of equipment, and so it's essential to specify the correct unit for the job in hand.

• Two overall considerations can be applied when deciding which is the right one: • First, it's essential to determine the correct details of the vehicle, its gearbox and the application required. When direct-mounted pumps are used, the pto is related to pump size and the hydraulic system.

• Secondly, it's necessary to choose the right pto which will do the job as efficiently and economically as is possible.

Edbro manufactures a complete range of power take-offs which can be fitted to gearbox tops or sides as well as special adaptations for gearboxes with rear mounted pto take-offs.

By using varying types of interchangeable controls, which can be either air or mechanically powered, with suitable adaptors the Edbro ptos can be fitted for virtually every type of truck transmission.

In addition Edbro offers a complete range of pumps which can be mounted and driven by a shaft from the gearbox pto.

With a shaft-driven pto it's the required horsepower and speed of the pto output shaft which decides which unit is needed, whereas for a pump drive the type of unit is decided by the desired pump output (delivery) and pressure.

Once these details are decided it is then possible to sort out the correct pto by knowing the truck transmission and by using the Edbro catalogue no. E3630.

In addition it's necessary to pick the right pipe adaptors for both inlet and outlet. Again these are decided using the application chart.

Now the correct pto series can be found from the chart. If only the transmission type of the truck is known the make and model of the vehicle can be located from the catalogue. This gives the catalogue page number of the pto needed which in turn gives the part number of the pto. All other parts and the type of adaptor required are also shown.

On combined units the pto part number shown is arranged to indicate correct pump speed.

Edbro Swash plate pumps can be operated in either direction without the need for alteration. This means that the pump is unaffected by fitting any adaptor which reverses the pump's direction.

For safety an efficient overload valve must be fitted in the main high-pressure pump delivery line in front of any other valves and as near to the pump as possible.

Finally the inlet pipe must comply with Edbro specifications and the oil used must be a clean mineral oil.

The best viscosity to give maximum pump output performance, Edbro recommends, is 150-500 Red No. 1 secs (57162 Engler 170/ 600 SUS). These are to be at the local air temperature where the equipment is to be used,

Using a higher viscosity oil will tend to reduce the output of the pump.

For a short-drive pto there are several points to take into consideration when endeavouring to select the right equipment: • It's essential to determine the exact make and model of the vehicle's gearbox and to find out the maximum and minimum speeds of the equipment to be driven.

*Certain vehicles have a recommended engine speed when running ancillary equipment and this too must be taken into account.

• The maximum horsepower required to drive the ancillary equipment must also be known so that before selecting a pto the torque rating of the application can be checked to establish whether it's within the range of ptos available.

• Although certain types of equipment can be driven in either direction this is not true of everything. If in doubt the rotational direction should be verified by the makers.

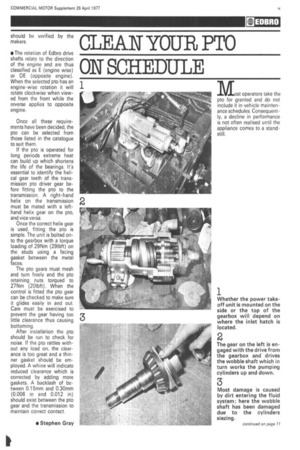

• The rotation of Edbro drive shafts relate to the direction of the engine and are thus classified as E (engine wise) or OE (opposite engine). When the selected pto has an engine-wise rotation it will rotate clockwise when viewed from the front while the reverse applies to opposite engine.

Once all these requirements have been decided, the pto can be selected from those listed in the catalogue to suit them.

If the pto is operated for long periods extreme heat can build up which shortens the life of the bearings. It's essential to identify the helical gear teeth of the transmission pto driver gear before fitting the pto to the transmission. A right-hand helix on the transmission must be mated with a lefthand helix gear on the pto, and vice versa.

Once the correct helix gear is used, fitting the pto is simple. The unit is bolted onto the gearbox with a torque loading of 29Nm (29Ibft) on the studs using a facing gasket between the metal faces.

The pto gears must mesh and turn freely and the pto retaining nuts torqued to 27Nm (20Ibft). When the control is fitted the pto gear can be checked to make sure it glides easily in and out. Care must be exercised to prevent the gear having too little clearance thus causing bottoming.

After installation the pto should be run to check for noise. If the pto rattles without any load on, the clearance is too great and a thinner gasket should be employed. A whine will indicate reduced clearance which is corrected by adding more gaskets. A backlash of between 0.15mm and 0.30mm (0.006 in and 0.012 in) should exist between the pto gear and the transmission to maintain correct contact.

• Stephen Gray