Stability and Economy will 000-gallon Load

Page 44

Page 45

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

Dennis Centaur Tractor with Scammell Semitrailer and Thompson Tank Carrying Full Load has High Acceleration and Braking Performance

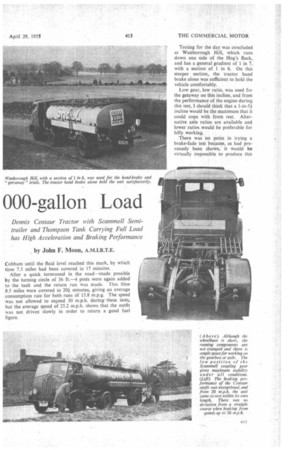

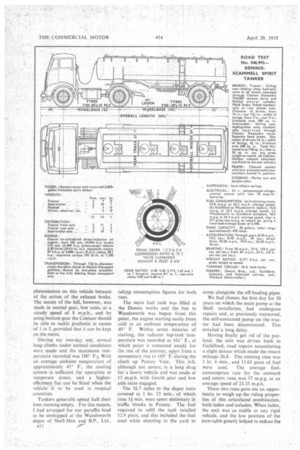

s by John E Moon, A.M.I.R.T.E. ALTHOUGH specified as suitable for a gross vehicle weight of 15i tons, the Dennis Centaur tractor was originally evolved for use, with 2,000-gallon tank semitrailers which, when carrying spirit, operate at a little over 13i tons. Thus, although the unit was run at 2 tons below its permitted maximum weight, it was appropriate that it should be tested in that form.

1. In addition to displaying marked economy during a typical delivery run—laden one way and unladen the other—the test showed that even with a liquid load it was possible to obtain rapid and safe deceleration with an articulated vehicle by paying careful attention to suspension and weight distribution.

The outfit had been lent by ShellMex and B.P., Ltd., and was thoroughly . run-in. . nit tractor, which is essentially a short-wheelbase version of the Centaur 8-ton loadcarrier, was fitted with a steel cab.

An addition to the standard specification included a Clayton-Oetiker exhaust obturator, this being the vehicle which had previously, been subjected to a test by The Conttner.cial Motor (March 25) to assess the power of this form of braking.

Tractor Modified

Minor modifications to the tractor had been effected to comply with Home Office regulations applying to spirit-carrying vehicles. These included the omission of a roof vent and the provision of a fire wall behind the cab. A power .take-off drove a pump for loading and unloading, but was not connected up on the test vehicle, which was later to prove a slight handicap to the full completion of the test. The Scammell semi-trailer carried a Thompson Bros. 2,000-gallon fourcompartment tank.

The test load consisted of 2,000 gallons of aviation paraffin and, complete with this load, driver, two passengers and test equipment, the gross vehicle weight totalled 13 tons 14,1cwt. The front axle carried 2 tens 1 l cwt. and an unladenweight check made later indicated that only T cwt. of the payload was imposed on the front axle.

A flat stretch of concrete road at the head of the Godalming By-pass, near Milford, provided a suitable surface for the braking tests: B10 Normally when making a " crash" stop for test purposes, the clutch is disengaged as the brakes are applied, thus ensuring that retardation is not assisted by the engine braking effect.

Because of the exhaust brake equipment this practice was not followed in the case of the Dennis and

• from 23 m.p.h. two sets of figures were taken. Without using the exhaust brake, the average stopping distance was 27 ft. 6 in., but by leaving the clutch engaged until the last moment, the unit was brought to a stop in 24 ft. How much of this was due solely to the exhaust brake, and how much to the normal braking effect of the engine, is difficult to say, but at least the figures showed a marked improvement in the second set of tests.

From 30 m.p.h. the average stopping distance was 54 ft. and this figure was obtained in the conventional manner without using the engine. I was a little worried as to the wisdom of making a " crash " stop from this speed, but on each occasion the unit came to rest in a straight line and the figures bear evidence of the trouble taken to arrive at the best possible weight distribution which would give maximum deceleration. .

The old Portsmouth road at Peasmarsh was chosen for the acceleration runs and I gave the driver a free hand to change the axle ratios during each run, in order to achieve the best times. By starting off in second gear, low ratio, then changing to high, then to third, then low fourth and finally high fourth, the times of 14.2 sec. and 39 sec. were obtained during the 0-20 m.p.h. and 0-30 m.p.h. tests respectively.

The more usual method of going through second, third and fourth gears in low ratio and then changing into high ratio produced a slightly lower time up to 20 m.p.h. and no appreciable difference up to 30 m.p.h.

Good Acceleration

Low ratio and direct drive in the gearbox were used fok the rollingstart tests and produced satisfactory figures. Road speed increased without any noticeable transmission vibration and the good torque characteristics of the 5.5-litre engine gave a fast time up to 20 m.p.h. These acceleration figures are above average for an articulated unit with this size of engine and compare favourably with those obtained from the 8-ton rigid chassis.

The main Portsmouth road .(A3) between Guildford and Cobham is undulating and busy, and is, therefore, most suitable for fuel-consumption tests, being typical of British road conditions. A test tank had been fitted and 4 pints of fuel were added above a pre-determined mark. The unit was then" run towards

Cobham until the fluid level reached this mark, by which time 7.3 miles had been covered in 17 minutes.

After a quick turnround in the road—made possible by the turning circle of 36 ft.-4 pints were again added to the tank and the return run was made. This time 8.5 miles were covered in 20-ii minutes, giving an average consumption rate for both runs of 15.8 m.p.g. The speed was not allowed to exceed 30 m.p.h. duringthese tests, but the average speed of 25.2 m.p.h. shows that the outfit was not driven slowly in order to return a good fuel figure.

Testing for the day was concluded at Wanborough Hill, which runs down one side of the Hog's Back, and has a general gradient of 1 in 7, with a section of 1 in 6. On this steeper section, the tractor hand brake alone was sufficient to hold the vehicle comfortably.

Low gear, low ratio, was used for the getaway on this incline, and from the performance of the engine during this test, I should think that a 1-in-5i incline would be the maximum that it could cope with from rest. Alternative axle ratios are available and lower ratios would be preferable for hilly working.

There was no point in trying a brake-fade test because, as had previously been shown, it would be virtually impossible to produce this

phenomenon on this vehicle because of the action of the exhaust brake. The ascent of the hill, however, was made in second gear, low ratio, at a steady speed of 8 m.p.h., and by using bottom gear the Centaur should be able to tackle gradients in excess of 1 in 5, provided that it can be kept on the move.

During my two-day test, several long climbs under normal conditions were made and the maximum temperature recorded was 180° F.) With an average ambient temperature of approximately 45° F., the cooling system is sufficient for operation in temperate zones, and a higherefficiency fan can be fitted when the vehicle is to be used in tropical countries.

Tankers generally spend half their lives running empty. For this reason, 1 had arranged for our paraffin load to be unshipped at the Wandsworth depot of Shell-Mex and BP:, Ltd..

B12 taking consumption figures for both runs.

The main fuel tank was filled at the Dennis works and the run to Wandsworth was begun from this point, the engine starting easily from cold in an ambient temperature of 40° F. Within seven minutes of starting, the radiator top-tank temperature was recorded as 161° F., at which point it remained steady for the rest of the journey, apart from a momentary rise to 169° F. during the climb up Putney Vale. This hill, although not severe, is a long drag for a heavy vehicle and was made at 15 m.p.h. with fourth gear and low axle ratio engaged.

The 26.7 miles to the depot were covered in 1 hr. 12 min., of which time If min. were spent stationary in traffic blocks in Putney. The fuel required to refill the tank totalled 12.9 pints, and this included the fuel used while shunting in the yard to come alongside the off-loading pipes.

We had chosen the first day for 10 years on which the main pump at the Shell installation had undergone repairs and, as previously recounted, the self-contained pump on the tractor had been disconnected. This entailed a long delay.

Having finally got rid of the payload, the unit was driven back to Guildford, road repairs necessitating a slight detour which made the return mileage 26.8. The running time was 1 hr. 6 min., and 11.65 pints of fuel were used. The average fuelconsumption rate for the outward and return runs was 17 m.p.g. at an average speed of 23.35 m.p.h.

These two runs gave me an opportunity to weigh up the riding properties of this articulated combination, both laden and unladen. When laden, the unit was as stable as any rigid vehicle, and the low position of the turn-table greatly helped to reduce the ,itching often experienced with prime foyers, especially when hauling a iquid load.

This pitching was, naturally mough, discernible when running ight, but was not sufficient to nfluence the handling of the vehicle. drove the tractor unit by itself, and it speeds in excess of 50 m.p.h. it was luite safe to handle despite the short vheelbase. The ride was somewhat lard, but no untoward swaying )ccurred when either cornering or 'raking.

Engine Noise Amplified When running normally under oad, the engine noise was fairly )ronounced, but was undoubtedly implified by the all-steel cab and vould be less in a chassis with the titernative coachbufit cab. The loise of the pedal-actuated exhaust )rake was almost unpleasant and was iccentuatecl by the presence of the iir cleaner in front of the mate's seat. )n current models the air cleaner las been moved to a position partly )eneath the floorboards.

The gearbox is easy to use and all :ontrols are well placed and light n operation. The driving seat is idjustable for height and fore-andtit position, and the deep two-piece mening windscreen gives good brward vision.

Maintenance of an articulated unit ractor is normally straightforward, )ecause, with the semi-trailer -emoved, there is no body to impede iccess to the running components. n a forward-control vehicle, howwer, the engine is often difficult to ervice because of the positions of :owling, controls and seats. Access n the Dennis engine is first-class, and when the cowl sections have been .emoved all the normal maintenance asks can be carried out without :ontortion.

Bonnet Easily Removed The cowl is in three sections, coniisting of two sides which are secured )3T two spring-clips and a curved top 3anel fastened by four screws. It is Jrifortunate that these screws are -Wed with loose nuts, the provision of :aptive nuts being relatively cheap 3ut saving time and patience.

With the near-side bonnet-side -emoved, the oil filler, dipstick, feed)ump priming-lever and injector)ump bleeder valve are easily -cached, and removal of the other fide gives access to the greaser for the gear-lever ,ball.

On removal of the top, the whole !nine is opened up to view, exposing the twin tappet covers, which are !ach secured by three nuts; the injectors, which are sensibly located by clamps bearing on the top caps, thus ensuring true location on replacement; the fuel filter, which is well-placed for changing the paper element, and such rarely troublesome items as the vacuum valve for the axle change, the speedometer drive correction box and the dynamo terminals. The separate belts for the fan and dynamo drives are not easy to reach from inside the cab.

All normal filler caps and plugs are well exposed. The gearbox has a large-bore filler and separate dipstick, and the rear axle has a level plug in the rear cover. A separate reservoir for the hydraulic braking system is mounted in the cab alongside the driver's seat, where toppingup is easy and the risk of dirt entering the tank is remote. The filler plug for the steeringbox can be reached by sliding back a small trap in the floor.

Batteries Under Seats Two 12-v. batteries are located underneath the driver's and mate's seats respectively, which must be removed for complete access. The driver's seat can be detached by winding the seat up and forward and removing the pin which secures it to its supporting frame.

A simple catch locates the mate's seat, and when this is released the seat can be tipped up and unhooked from its upper brackets.

From underneath the engine it is easy to reach the sump drain plugs, remove and clean the sump-oil Wainer and detach the cover plate for the main suction pipe. The large lubricating-oil filter and cooler is on the left-hand side of the engine and the felt filter element can be removed by unscrewing the securing bolt for the filter casing. The oil-pressure relief valve is in the filter mounting tilock and is reached from inside the cab.

Central Instruments Instruments, switches and fuses are grouped in the central instrument panel. This has a pressed-steel cover which can be removed by unscrewing four knurled screws, thereby exposing the complete equipment. The box surrounding the air cleaner has a detachable panel secured by two screws and its removal enables the filter to be withdrawn from the induction hose for cleaning and refilling.

There are 35 grease nipples. The four bleeding nipples for the braking system are easy to reach and the brakes are adjusted by two hexagonal adjusters on each front wheel and one square-headed adjuster on each rear wheel.

The Gitlin brakes of the semitrailer also have square-headed adjusters and the linkage rods can be taken up when excessive play occurs. The trailer has 19 grease nipples, 12 of which are placed around the turntable and jockeywheel gear.