GREEN SPECIAL VEHICLE DESIGN

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

• A "green" refuse collection vehicle designed by a student — with separate drums for bottles and waste paper to encourage recyling — would last two years longer than most refuse trucks on the market. But the prototype is unlikely to be taken up by a manufacturer. It is one of three commercial vehicle concepts dreamed up by industrial design students at Coventry Polytechnic as part of their degree show.

Around 30 students complete the fouryear degree each year. They are swiftly poached by leading car, bus and commercial vehicle manufacturers, including Rover, Nissan, Land-Rover and Motor Panels, who attend the degree show in search of talent.

"Few of the designs go further," says David Browne, who has taught the course for 10 years. "The show allows students to show themselves to be all-rounders, capable of thinking conceptually and commercially."

The green dustcart, by Mark Healy, followed research into the market where he found the average working life for current fleets based on standard truck chassis was five years. He thought that if this could be extended to seven and increased production costs could be recouped.

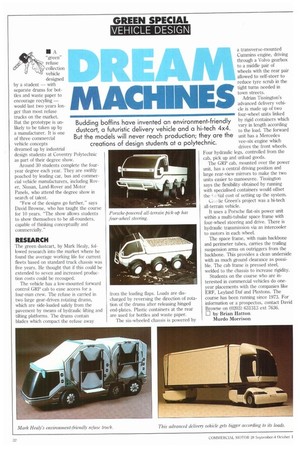

The vehicle has a low-mounted forward control GRP cab to ease access for a four-man crew. 'rhe refuse is carried in two large gear-driven rotating drums, which are side-loaded safely from the pavement by means of hydraulic lifting and tilting platforms. The drums contain blades which compact the refuse away Porsche-powered all-terrain pick-up has four-wheel steering.

from the loading flaps. Loads are discharged by reversing the direction of rotation of the drums after releasing hinged end-plates. Plastic containers at the rear are used for bottles and waste paper.

The six-wheeled chassis is powered by a transverse-mounted Cummins engine, driving through a Volvo gearbox to a middle pair of wheels with the rear pair allowed to self-steer to reduce tyre scrub in the tight turns needed in town streets.

Adrian Tissington's advanced delivery vehicle is made up of two four-wheel units linked by rigid containers which vary in length according to the load. The forward unit has a Mercedes vee-six engine which drives the front wheels. Four hydraulic legs, controlled from the cab, pick up and unload goods.

The GRP cab, mounted over the power unit, has a central driving position and large rear-view mirrors to make the two units easier to manoeuvre. Tissington says the flexibility obtained by running with specialised containers would offset the i ii:tial cost of setting up the system.

Li' 11 lie Green's project was a hi-tech all-terrain vehicle.

It uses a Porsche flat-six power unit within a multi-tubular space frame with four-wheel steering and drive. There is hydraulic transmission via an intercooler to motors in each wheel.

The space frame, with main backbone and perimeter tubes, carries the trailing suspension arms on outriggers from the backbone. This provides a clean underside with as much ground clearance as possible. The cab frame is pressed steel, welded to the chassis to increase rigidity.

Students on the course who are interested in commercial vehicles do oneyear placements with the companies like ERF, Leyland Daf and Plaxtons. The course has been running since 1973. For information or a prospectus, contact David Browne on (0203) 631313 ext 7636. Ei by Brian Hatton Murdo Morrison