Serrations and splines

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

THERE are many components on motor vehicles which have to be located on a shaft so that they do not revolve on the shaft but turn with it. The drop arm on a steering-box cross-shaft, for example, must be so fastened that it is locked solid on the shaft but at the same time is secured in such a way that it can be removed from the shaft when it is necessary to dismantle the steering box for repair.

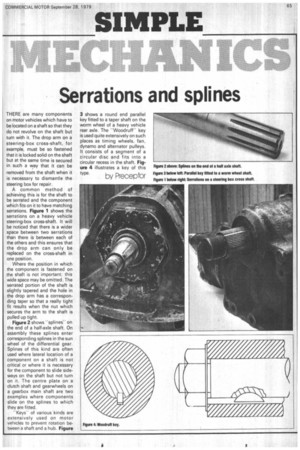

A common method of achieving this is for the shaft to be serrated and the component which fits on it to have matching serrations. Figure 1 shows the serrations on a heavy vehicle steering-box cross-shaft. It will be noticed that there is a wider space between two serrations than there is between each of the others and this ensures that the drop arm can only be replaced on the cross-shaft in one position.

Where the position in which the component is fastened on the shaft is not important; this wide space may be omitted. The serrated portion of the shaft is slightly tapered and the hole in the drop arm has a corresponding taper so that a really tight fit results when the nut which secures the arm to the shaft is pulled up tight.

Figure 2 shows "splines" on the end of a half-axle shaft. On assembly these splines enter corresponding splines in the sun wheel of the differential gear. Splines of this kind are often used where lateral location of a component on a shaft is not critical or where it is necessary for the component to slide sideways on the shaft but not turn on it. The centre plate on a clutch shaft and gearwheels on a gearbox main shaft are two examples where components slide on the splines to which they are fitted.

"Keys" of various kinds are extensively used on motor vehicles to prevent rotation between a shaft and a hub. Figure

3 shows a round end parallel key fitted to a taper shaft on the worm wheel of a heavy vehicle rear axle. The "Woodruff" key is used quite extensively on such places as timing wheels, fan, dynamo and alternator pulleys. It consists of a segment of a circular disc and fits into a circular recess in the shaft. Figure 4 illustrates a key of this type.

by Preceptor