Auto lube saves servicing costs

Page 124

Page 125

If you've noticed an error in this article please click here to report it so we can fix it.

By CVs FgieerLg Hdior

WHATEVER job a lorry is employed for, maximum use is of prime importance. It is here that an automatic chassis lubrication can pay dividends by cutting down on maintenance costs.

Chassis bearings, steering joints, king pins, shackles, etc which are normally accepted as parts which need replacement, can often be expected to last without change.

The systems in current use can be divided into three basic categories:

H Multi-line systems;

I I Single-line resistance systems;

7 Single-line positive displacement.

The multi-line system is normally reserved for heavy lorries and city buses. Although they can be used for grease, about 95 per cent of the users prefer oil. The system is normally used where an air circuit is available although versions have been produced which are compatible with hydraulic or vacuum braked vehicles. The timing of the lubrication cycle is usually worked out on a mileage basis, eg, one shot of oil per 11/2 miles.

The single-line resistance system relies on the resistance of a small metering unit at or near each bearing to proportion the flow of oil. This system is generally used for light/medium weight vehicles (or trailers) and is often driven by a gearboxmounted mechanical pump or a pneumatically operated pump controlled by an electronic timer...These. account for about 90 per cent of single-line resistance applications.

Unlike the systems already mentioned, the positive displacement type is controlled by metering valves at each bearing which inject a predetermined volume each time the system is pressurised. Depending on the size of the vehicle, the frequency of lubrication is set at about 30 minutes for oil and about two hours for grease.

All these systems are applicable to conventional roadgoing vehicles whether used for farm transport or not, but there are also automatic lubrication systems to cater for most agricultural machinery like hay balers and harvesters.

As an example. the Interlube ITL chain lubrication system comprises an oil reservoir, a lever-operated piston pump and a ring main distribution circuit terminating in individual metering units. It can be used to lubricate chain drives as well as conventional bearings.

For equipment operating in extreme conditions of mud, grit, salt or sand, Interlube markets the AGS grease system, which takes its power from the vehicle's air supply. Controlled by a solid-state timer, the cycle time can be varied from 10 seconds to four minutes.

Which lubricant to use — oil or grease — is not an easy question to answer as it depends on which manufacturer we are talking about. Both systems have their adherents.

The lubricant most commonly used is a gearbox oil, the viscosity of which is selected according to the temperatures likely to be encountered with

the usual grade for "normal UKconditions being SAE 90. Engine oil is not normally recommended owing to its low viscosity, which can cause the oil to drip out of the bearings.

One company which prefers the grease method is LincolnHelios with its Quicklub. This system operates on a time basis where, at preset intervals after energising the ignition circuit, all connected points are supplied with grease. The grease is delivered to each of the bearings via a progressive piston displacement sequence through each of the distributors in the system.

This progressive piston displacement ensures that each point receives its correct quantity of lubricant regardless of the varying resistance of the bearing in question. The Quicklub system takes standard chassis grease in bulk.

Which tyres?

In simple terms, tyres for farm use can be divided into three sections: Front wheels of tractors; tractor drive wheels; implements.

The first type normally has three ribs and is of cross-ply construction. It is intended for use as a steering tyre in soft going. It is not suitable for an on-road operation or even extensive use on a concrete yard as the wear rate is very high under these conditions.

If the tractor is to be used for a lot of on-road work then a good compromise is to use a LandRover tyre as this is the correct size and a suitable tread pattern.

Although some years behind the road haulage industry, the rear wheels of tractors are now showing a trend towards radial-ply types. The tyre companies claim that the radial design gives a longer life when used on the road, but, an equally important point, they are more resistant to punctures.

The third category to consider is that of farm implements

and this can be a big headache for the farmer because such tyres come in such a diversity of sizes. Many are produced by small companies, literally along the lines of "one-offsas opposed to the mass production availability from factories like Michelin and Dunlop.

One point to watch concerning an imported piece of equipment is whether the tyre size is a regularly available type or whether the operator will have to apply through the importer to obtain a replacement not an unusual occurrence.

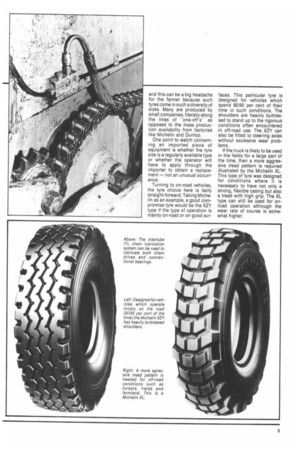

Turning to on-road vehicles, the tyre choice here is fairly straight-forward. Taking Michelin as an example, a good compromise tyre would be the XZY type if the type of operation is mainly on-road or on good sur

faces. This particular tyre is designed for vehicles which spend 90/95 per cent of their time in such conditions. The shoulders are heavily buttressed to stand up to the rigorous conditions often encountered in off-road use. The XZY can also be fitted to steering axles without excessive wear problems.

If the truck is likely to be used in the fields for a large part of the time, then a more aggressive tread pattern is required illustrated by the Michelin XL. This type of tyre was designed for conditions where it is necessary to have not only a strong, flexible casing but also a tread with high grip. The XL type can still be used for onroad operation although the wear rate of course is somewhat higher.