Air - cooled V - 12 Oil Engine

Page 86

Page 89

Page 90

Page 91

Page 92

If you've noticed an error in this article please click here to report it so we can fix it.

This 11-litre unit has a gross power output of 180 b.h.p. at 2,300 r.p.m., and has a V-cylinder formation. The cylinders and heads are shrouded and air is forced over them by means of a large cowled fan. The Deutz engine is of German manufacture, but air-cooling is also employed in the Czech Tatra design (Stand 103). This is a V-12 unit employing direct injection. Its cubic: capacity is 14.825 litres and 180 b.h.p. is developed at 1,800 r.p.m., although it can be uprated to give 220 b.h.p. at 2,200 r.p.m. A new version, used in the Praga chassis, develops 98 b.h.p. at 2,100 r.p.m.

Other than the engine employed in the Thornycroft Big Ben (Stand 87), the only turbo-blown oil engines at the Show are the Volvo 185 b.h.p. (Stand 98) and the Meadows engine of the same power output. Eberspacher blowers are employed and as used on the Volvo raise the power output from 150 b.h.p., an increase of 23 per cent. Because turboblowing can normally be expected to raise power output by a third, as with the Meadows unit, it is reasonable to suppose that the Volvo engine could be further uprated from 185 b.h.p. should the need arise.

Anew version of the Perkins R6 (V) (Stand 438 QR) has been introduced following the teething troubles of the original unit. The revised engine delivers 104 b.h.p. at 2,500 r.p.m., with a maximum torque output of 240 lb.-ft. at 1,600 r.p.m. Several modifications have been incorporated, including an improved automatic timing-chain tensioner, a moulded plastics tensioner pad, improved oil flow to the chain and alterations to the crankshaft seals, valves and cylinder-head gasket.

A new type of air cleaner has been introduced by Automotive Products. Ltd. (Stand 359 G). It is known as the

Purolator Micronic filter and has a throw-away plasticsimpregnated paper element. The new filter requires no oil, and element replacement can be carried out in under half a minute. The filter does not, however, give the same silencing effect as an oil-bath unit.

Whilst there are few engine developments, the same cannot be said in the field of transmissions. In 1954, semiautomatic transmission systems, such as the Leyland airoperated Pneumo-Cyclic and the A.E.C. electro-pneumatic Monocontrol, were introduced. The advantages that these systems gave in reducing driving fatigue and increasing passenger comfort were ' immediately realized, whilst both systems had the further advantage that their control could be readily understood by inexperienced drivers.

Both are developments of the Self-Changing Gear company's epicyclie design. A third system, as used on the Atkinson double-decker chassis, employs an electrohydraulic change mechanism. The most recent development is the new V.S. electrical control which is seen on a Leyland double-decker in the demonstration park.

Essentially, the control consists of a D.C. generator, driven by the 'output shaft of the gearbox, the output of which is proportional to the speed of the vehicle. The generator actuates a series of relays, which control the gearbox valves, and upward changes are made at predetermined voltage increases. Similarly, downward changes are made as the generator output falls. The essential advantage of this system is that it is relatively easy to apply fo any existing semi-automatic epicyclie gearbox and the additional equipment required is not bulky or expensive.

Other new transmission units developed by Self-Changing Gears, Ltd. (Stand 435 R), include the RU 30 eight-speed gearbox, which is employed on the Leyland Buffalo (Stand 85). Although not fully automatic in operation, gear-changing is extremely simple add several safety features are incorporated. The box consists of a four-speed main section with a two-speed auxiliary section.

Operation is on the electro-pneumatic principle and the change-speed lever is moved forward for upward changes and back wards for downward changes, returning to centre after each change. A governor on-the gearbox ensures that downward changes are impossible when the engine cannot be speeded up sufficiently to synchronize with the road speed. This governor automatically effects downward changes as far as fifth ratio when the road speed is reduced. This has the•effect of making the box fully automatic for normal road work.

'Another safety feature is that the electrical circuit is controlled by a master switch and the engine cannot be started

until connection is made at this switch. The switch is operated by a key which, when withdrawn, automatically puts the gearbox in neutral. This means that the vehicle cannot be parked in gear, neither can it be started with a gear engaged.

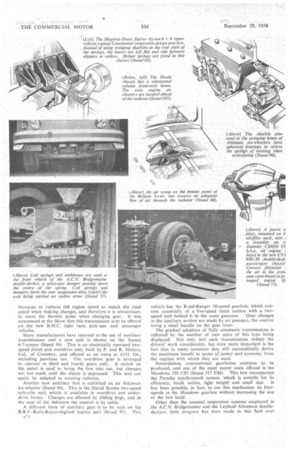

These types of gearbox are commonly employed in conjunction with a conventional hydraulic coupling, but all hydraulic couplings suffer the disadvantage of drag at idling speed and slight slip at maximum speed. To overcome this disadvantage whilst retaining the benefit of the cushioning effect of the oil, Self-Changing Gears, Ltd. have introduced a fluid coupling which combines a centrifugal clutch. Idling drag is not eliminated but a positive drive is given at normal road speed with .a resultant improvement in transmission efficiency.

Epicyclic gearboxes, in conjunction with a centrifugal friction clutch arc featured on two vehicles, these being the Leyland Atlantean (Stand 85) and the Daimler doubledecker (Stand 73). The Leyland unit is of their own design and has a single friction disc controlled by six bob weights.

The Daimler chassis has a Twiflex clutch, which employs six rubber-mounted friction segments. In this design a rubber coupling behind the clutch removes any possible transmission harshness.

SUPPORTING SYNCHRONIZER RING SLIDING RING SLEEVE LOCKING

A new Rolls-Royce

transmission is the Hydro-dynamic torque converter (Stand 436 R), built under licence from the American Twin Disc Co. This torque converter has a centrifugal-type fluid pump driven by the engine, and a centrifugal turbine driven by the fluid.

The device differs from a conventional fluid coupling, however, in that it can multiply the output torque of the engine at low engine speeds. The output to input torque ratios can vary from 5.3 to 1, to 1 to 1, progressively, as the speed of the output shaft increases from zero to maximum.

Another torque converter is shown on the Self-Changing Gears stand. This is based on the Schneider principle and should be suited for use in heavy vehicles.

In view of the developments with fully and semi-automatic

transmissions in private-car fields, there are obvious adaptations for using such mechanisms in light delivery vans. The Standard Motor Co., Ltd., are exhibiting two 6-cwt. vans which employ Standrive two-pedal control, based on the Newtondrive system (Stand 71). This consists of a centrifugal clutch with a vacuum servo-actuated overriding-control. This control is actuated by a pressure-sensitive •switch in the gear-change lever knob.

Linkage between the solenoid valve controlling the clutch actuation and the throttle pedal ensures that the engine is speeded up slightly as the clutch is withdrawn, thus tending to synchronize engine and road speeds and reduce transmission shocks. For fast downward changes an additional linkage from the accelerator pedal opens an air valve in the control valve unit which admits additional air to the back of the clutch withdrawal servo to give rapid clutch re-engagement when the throttle pedal is depressed.

Another two-pedal control system, demonstrated on the Turner oil-engined delivery van, is the Manumatic control, developed by Automotive Products, Ltd. A centrifugal clutch is employed in this system also, and a gear-lever knob switch actuates a vacuum servo for clutch withdrawaL A synchronizing control on the clutch automatically increases or reduces thE engine speed to match the road speed when making changes, and therefore it is unnecessary to move the throttle pedal when changing gear. It was announced at the Show that this transmission is to be offered • on the new B.M.C. light vans, pick-ups and passenger vehicles.

Many manufacturers have resorted to the use of auxiliary transmissions and a new unit is shown on the Jensen 6-7-tonner (Stand 56). This is an electrically operated twospeed direct and overdrive unit, built by P. and R. Motors, Ltd., of Coventry, and offered as an extra at E112 10s., including purchase tax. The overdrive gear is arranged to operate in third and fourth gears only. A switch on the panel is used to bring the box into use, but changes are not made until the clutch is depressed. This unit can easily be adapted to existing vehicles.

Another new auxiliary box is exhibited on an Atkinson six-wheeler (Stand 96). This is the David Brown two-speed epicyclic unit, which is available in overdrive and underdrive forms. Changes are effected by sliding dogs, and in the case of the Atkinson the control is by cable.

A different form of auxiliary gear is to be seen on the E.R.F.-RolIs-Royce-engined tractor unit (Stand 97). This vehicle has the Road-Ranger 10-speed gearbox, which consists essentially of a five-speed main section with a twospeed unit behind it in the same gearcase. Gear changes in the auxiliary section are made by air pressure, the control being a small handle on the gear lever.

The gradual adoption of fully automatic transmissions is reflected by the number of new units of this type being displayed. Not only will such transmissions reduce the drivers' work considerably, but even more important is the fact that in many instances they will automatically derive the maximum benefit in terms of power and economy from the engines with which they are used.

Nevertheless, conventional gearboxes continue to be produced, and one of the most recent units offered is the Meadows 250 CS5 (Stand 317 EM). This box incorporates the Porsche synchromesh system, which is notable for its efficiency, baulk action, light weight and small si4e. It has been possible, in fact, to use this mechanism on fourspeeds in the Meadows gearbox without increasing the size of the box itself.

Other than the unusual suspension systems employed in ..the A.C.V. 13ridgernaster and the Leyland Atlantean doubledeckers, little progress has been made in this field over recent years. The Leyland Buffalo is one of the few heavy goods vehicles to have fully progressive leaf springs at the front axle, and so long as leaf springs continue to be in vogue, this seems likely to be the only improvement possible on goods chassis, although hydraulic dampers will continue to be in use. Rubber suspension, using Andre-Neidhart units, is featured on the rear axle of the Turner delivery van (demonstration park).

Air springing has for several years been in use in the United States and has again appeared in Great Britain. An air-spring unit is shown on the Silentbloc stand (299 CM), and it is understood that similar units have been in use on certain vehicles of a large fleet for some time with encouraging success.

The variable-rate air-spring .offers many advantages in respect of riding comfort: it can be easily adjusted to compensate for varying loading and uneven weight distributions, and it gives constant height irrespective of load. Furthermore, the units are light and relatively small and therefore should not present any problems of adaptation to existing chassis. The progress of this unit will be watched with interest in view of its enormous potentialities on all classes of road vehicle.

The most noteworthy feature of braking, as seen at the Show, is the substantial swing by several manufacturers towards dual-braking systems. There are several different types featured on both goods and passenger vehicles.

On the Guy Warrior underfloor-engined'paSsenger chassis (Stand 63), a Benda-Westinghouse air-pressure system is used. This incorporates a new dual-reaction-valve unit from which there are separate air systems to front and rear axles. A similar layout has been chosen for certain vehicles of the A.C.V. group, whilst an Atkinson six-Wheeler (Stand 96) is shown with the new Clayton Dewandre TwinAtlas circuit.

The last-named consists of two Hydrovac units, operated from dual master-cylinders, which are controlled by the pedal through a balance-beam linkage. As used on the Atkinson, one braking system operates on the front and centre axles while the 'other operates on the rear axle and has trailer connections, The Leyland Atiantean employs a dual air-hydraulic system with twin air-hydraulic actuators located below the driving seat and as close to the brake pedal as possible. The Bridgcmaster has air-hydraulic brakes at the front wheels and air brakes on the rear wheels. All these systems are a big advance towards maximum road safety.

A different approach to the problem of providing braking should a power line fracture, is that used by Fodens (Stand 59). With their system, the footbrake actuates the wheel units through a constant-flow hydraulic system. Should power fail for any reason the pedal can be depressed past its normal travel, and it then operates a disc transmission brake.

This disc has two caliper units, the second of which is connected to the brake lever. The advantages of the disc brake for transmission units are many, not the least of which is that the risk of the brake overheating is considerably reduced. A disc transmission brake is also featured on the new Scammell Super Constructor (Stand 101). Constant improvements are being made to wheel units but so far, with the exception of certain Midland Red single-deckers, there are no vehicles in service with disc brakes at the wheels. With a view to reducing maintenance, several types of automatic adjuster are available and a new design is featured on Daimler vehicles (Stand 73). This is a Clayton Dewandre R.P. unit, which gives equal adjustment on both shoes.

The ever-increasing weights and speeds of commercial vehicles demand constant research into brake-facing materials, particularly with the advent of disc brakes. To this end, a new facing has been developed by Ferodo, Ltd. (Stand 295 C), in conjunction with Girling and Midland Red, for use in disc-brake pads. This material is known as DS I and is claimed to give high wear resistance and to withstand temperatures up to 500° C.

Facing manufacturers are frequently blamed for brake squeal, but the causes of brake squeal are too numerous to pinpoint. Tests have been made with vehicles by the

Motor Industry Research Association (Stand 13), and a device is exhibited which, it is claimed, can reduce brake squeal to a minimum. This consists of a metal ring faced with a friction material and pressed against the mouth of the drum by spring clips. Drum vibrations are absorbed and are prevented from building up to an audible level.

The only possible criticism of this system is that it could tend to reduce cooling. An excellent example of the manner in which heat builds up in a brake was seen shortly before the Show opened. The Italian-bodied Worldmaster coach has deeply shrouding body panels and dummy ventilating discs on the rear wheels. Six or _seven hours after the vehicle had been finally positioned on the Leyland stand, the brakes were still warm because of the lack of ventilation. Ventilating discs are to be seen on Duple-bodied vehicles: these direct a .flow of air on to the brakes where it is most needed (Stand 32).

Continued attention is being paid to reducing the work of drivers and mention Has already been made of the part automatic and semi-automatic transmissions play in• this respect. Increased use is now being made, however, of power assistance for the steering, and there are now few manufacturers of heavy vehicles who do not offer the system.