HEAVY HAULAGE

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

Heavy haulage is an area where it is essential to have the right equipment for the job—Gibb Grace surveys the type of tractors and trailers that can cope with the most demanding tasks.

0 f all the haulage sectors, heavy haulage is unique in that the vehides operate largely outside the normal Construction Se Use Regulations. Instead they run under the Special Types General Order, or STGO, in one or more of three main categories: ! • Category s—up to 46 tonnes

GCW;

1011, • Category 2—up to 8o tonnes , GCW;

• Category 3—up to 150 tonnes GCW.

I Time was when heavies consisted of ballasted trailers and drawbar-type trailers, but today even the heaviest Category 3 vehicles are normally tractors hauling heavy-duty semi-trailers.

Time has moved on since the current STGO regulations were introduced in 1989. With 4o, 41 and even 44 tonnes the norm in road haulage, Category r with its 46-tonne limit is now largely ignored. In any case, operators with a Category-2 combination can use it for Category-r work as long as the appropriate STGO plate is displayed.

The size and weight of plant has increased with time; by far the most popular sector today is Category 2, where vehicles can handle loads from 3o-5o tonnes.

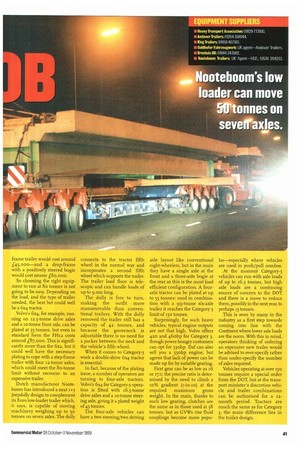

Because of this range, the types of vehicle are split between 6x2s and 6ms. Up to 65 tonnes gross the 6x2 configuration is probably the more economic solution. Tractors like the Daf 95 and Volvo Him have design weights of up to 26 tonnes, but they can be plated at up to 30 tonnes by specifying higher axle weights and a heavy-duty, double-reduction drive axle. Coupled to a semi-trailer with three 12.5tonne axles this gives a combination weight of 67.5 tonnes with a payload of around 40 tonnes.

This is a useful outfit that is reasonably economical to buy and operate, and covers the majority of plant transport oper ations, but it has its limitations. Typical 6x2 tractors with hubreduction drive axles can cope with 8o tonnes gross, but the loads are heavy enough to cause loading problems unless the trailer is specific to the equipment carried, or the tractive unit has plenty of spare axle capacity. At the lighter weights the trailer can have air-suspended axles which lower to aid loading; plant can be driven up folding ramps and positioned so that it sits partly on the bogie. With bigger, heavier equipment, however, loading in this way can be hazardous, particularly at night. It is certainly not advisable. Also, the load may be too high to pass under some bridges: either way, the only alternative is to use a drop-frame trailer which breaks at the neck, giving both the lowest possible deck and access to it.

This is all well and good, but more of the weight has to be carried by the tractor, and to achieve the maximum deck length the trailer has to be that much longer, impairing manoeuvrability.

This drawback can be overcome easily and extremely neatly by opting for a modern trailer with a steerable bogie.. but at a price. A conventional step-frame trailer will generally set you back £35,00037,000, but an equivalent drop

frame trailer would cost around f45,000—and a drop-frame with a positively steered bogie would cost nearer £80, 000.

So choosing the right equipment to run at 8o tonnes is not going to be easy. Depending on the load, and the type of trailer needed, the best bet could well be a 6x4 tractor.

Volvo's 6x4, for example, running on 12.5-tonne drive axles and a to-tonne front axle, can be plated at 35 tonnes, but even in standard form the FFII2 costs around £87,000. This is significantly more than the 6x2, but it could well have the necessary plating to cope with a step-frame trailer with four 12-tonne axles, which could meet the 8o-tonne limit without recourse to an expensive trailer.

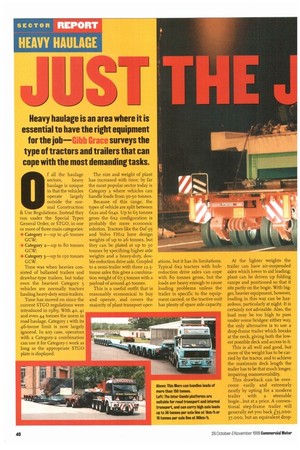

Dutch manufacturer Nooteboom has introduced a neat 1+3 jeepdolly design to complement its Euro low-loader trailer which, it says, is capable of moving machinery weighing up to 59 tonnes on seven axles. The dolly

connects to the tractor fifth wheel in the normal way and incorporates a second fifth wheel which supports the trailer. The trailer load floor is telescopic and can handle loads of up to 9,om long.

The dolly is free to turn, making the outfit more manoeuvrable than conventional trailers. With the dolly removed the trailer still has a capacity of 42 tonnes, and because the gooseneck is adjustable there is no need for a packer between the neck and the vehicle's fifth wheel.

When it comes to Category-3 work a double-drive 6x4 tractor is essential.

In fact, because of the plating issue, a number of operators are turning to four-axle tractors. Volvo's 6x4 for Category-3 operation is fitted with 16.5-tonne drive axles and a io-tonne steering axle, giving it a plated weight of 43 tonnes.

The four-axle vehicles can have a two steering/two driving axle layout like conventional eight-wheelers, but in the main they have a single axle at the front and a three-axle bogie at the rear as this is the most load efficient configuration. A fouraxle tractor can be plated at up to 53 tonnes: used in combination with a 99-tonne six-axle trailer it reaches the Category 3 limit of 15o tonnes.

Surprisingly, for such heavy vehicles, typical engine outputs are not that high. Volvo offers 420 and 46ohp for Category 3. though power-hungry customers can opt for 53ohp. Daf can also sell you a 53ohp engine, but agrees that lack of power can be made up for by suitable gearing.

First gear can be as low as 16 or 17:1; the precise ratio is determined by the need to climb a lo% gradient (I-in-io) at the required maximum gross weight. In the main, thanks to such low gearing, clutches are the same as in those used at 38 tonnes, but as GVWs rise fluid couplings become more popu

lar—especially where vehicles are used in push/pull combos.

At the moment Category-3 vehicles can run with axle loads of up to 16.5 tonnes, but high axle loads are a continuing source of concern to the DOT and there is a move to reduce them, possibly in the next year, to perhaps 15 tonnes.

This is seen by many in the industry as a first step towards coming into line with the Continent where lower axle loads are the norm. With this in mind, operators thinking of ordering an expensive new trailer would be advised to over-specify rather than under-specify the number of axles required.

Vehicles operating at over 150 tonnes require a special order from the DOT, but at the transport minister's discretion vehicle and trailer combinations can be authorised for a 12month period. Tractors are much the same as for Category 3; the main difference lies in the trailer design.