Foden Passenger Chassis Loaded to 10 tons Gross Weight and

Page 46

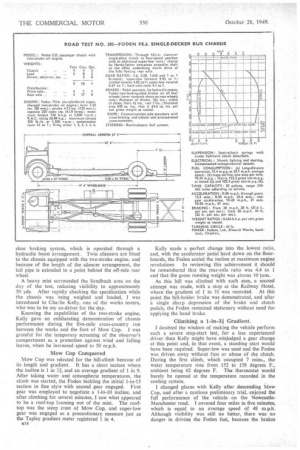

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

Equipped with Two-stroke Oil Engine and High-ratio Axle Climbs Mow Cop and Breaks Economy Records for its Class Maximum of 55 m.p.h. Can Be Maintained with Safety. Frame Construction and Suspension Make for Stability in Fast Cornering. Hill-holder Parking Brake Effective on I in 3 Gradient

By L. J. COTTON, m.I.R.T.E. STANDARDS of fuel consumption have to be revised when dealing with chassis equipped with the Foden supercharged six-cylindered 4.09-litre twostroke oil engine. My previous encounter with an eight-wheeler powered by this unit produced an alltime record in low fuel consumption, and a test of the Foden passenger chassis, with a production two-stroke engine, created a new record in its field. This performance was achieved despite the maintenance of a high average speed and rapid acceleration through the gears

and in direct drive .

The Foden two-stroke oil engine was fully described in "The Commercial Motor" on August 27, 1948, but to recapitulate. it has an output of 126 b.h.p. at 2,000 r.p.m and 350 lb.-ft. torque at 1,500 r.p.m. Its crankcase and cylinder block form a single-piece aluminium-alloy casting, with push-fit wet liners. The casting is divided horizontally into three main compartments—the water jacket (at the top), the air chest and the crank chamber. Rubber rings are inserted in grooves in the liners to seal the joints between the chambers

Conventional Gasket Fitted Normal gaskets replace the former joint rings at the top of the cylinder bores, whilst the water hole and tappet-guide holes are sealed by rubber grommets. Two nickel-iron head castings are fitted, each covering three bores, and there are two exhaust valves to each cylinder, their cast-iron guides being in direct contact with the cooling water.

A seven-bearing, unhardened nickel-steel crankshaft is employed, with steel-shell white-metal-lined bearings for the " mains " and big-ends. Tin-plated cast-iron

pistons are used, each having five rings A wide composite ring covers the top land, whilst two wedgeshaped compression rings are fitted immediately below the top land. An air-chest sealing ring, fitted below the gudgeon pin, prevents scavenge air from leaking

B12 through to the crankcase chamber when the piston is at the top of its travel, Helical gearing is used for all the timing arrangements, which are located at the rear of the unit. A skew gear at the front of the crankshaft drives a transverse shaft operating the water pump and the gear pump for the Foden liydraulic braking system. Geared to revolve at approximately twice engine speed, the Roots pattern blower incorporates two-lobe rotors. Air is drawn . through a filter and silencer, and is delivered direct to the air chest

The fuel-injection equipment includes a C.A.v hydraulically governed pump supplying fuel to singlehole injectors which are inclined at an angle of 45 degrees and spray tangentially into the combustion space. The combustion space is formed by the cavity in the piston crown and turbulence is obtained in the design of the ports at the base of the liners and by deflector vanes in the air chest.

Because of the smooth torque and absence of high stresses, the two-stroke unit can be fitted into the standard Foden chassis without the need for increasing the size of the transmission units.

A Comparative Test The model supplied for my test was the single-decker bus chassis. A test report of this type of vehicle, equipped with a conventional four-stroke engine, was published in "The Commercial Motor" dated June 6, 1947.

The engine, mounted in conjunction with the gearbox, is secured in the frame through Silentbloc rubber bushes, one being located at the front of the unit, and one on each side of the clutch housing. A four-speed gearbox, with an additional super-low gear, was fitted to the test chassis, the second, third and fourth ratios being in constant mesh.

Among its features, the Foden passenger chassis has a full-depth cross-bracing at the centre of the frame, recirculatory-ball steering and an efficient two-leading

shoe braking system, which is operated through a hydraulic boost arrangement. Twin silencers are fitted to the chassis equipped with the two-stroke engine, and because of the length of the silencer arrangement, the tail pipe is extended to a point behind the off-side rear wheel.

A heavy mist surrounded the Sandbach area on the day of the test, reducing visibility to approximately 50 yds. After rapidly checking the specification while the chassis was being weighed and loaded, I was introduced to Charlie Kelly, one of the works testers, who was to be my co-driver for the day.

Knowing the capabilities of the two-stroke engine, Kelly gave an exhilarating demonstration of chassis performance during the five-mile cross-country run between the works and the foot of Mow Cop. I was grateful for the temporary screening of the observer's compartment as a protection against wind and falling leaves, when he increased speed to 50 m.p.h.

Mow Cop Conquered

Mow Cop was selected for the hill-climb because of its length and gradient. It has a short Section where the incline is 1 in 3, and an average gradient of 1 in 9. After taking water and atmospheric temperatures, the climb was started, the Foden tackling the initial 1-in-15 section in fine style with second gear engaged. First gear was employed to negotiate a 1-in-10 incline, and after climbing for several minutes, I saw what appeared to be a roof-top looming out of the mist. The rooftop was the steep crest of Mow Cop, and super-low gear was engaged as a precautionary measure just as the Tapley gradient meter registered 1 in 4.

1114 Kelly made a perfect change into the lowest ratio, and, with the accelerator 'pedal hard down on the floorboards, the Foden scaled the incline at maximum engine revolutions In reviewing this achievement it should be remembered that the rear-axle ratio was 4.4 to 1 and that the gross running weight was almost 10 tons.

As this hill was climbed with such ease, a second attempt was made, with a stop at the Railway Hotel, where the gradient of I in 31 was recorded. At this point the hill-holder brake was demonstrated, and after a single sharp depression of the: brake and clutch pedals, the Foden remained stationary without need for applying the hand brake.

Climbing a 1-in-3i Gradient.

I doubted the wisdom of making the vehicle perform such a severe stop-start test, for a less experienced driver than Kelly might have misjudged a gear change. at this point and, in that event, a standing start would have been required. Super-low was used and the Foden was driven away without fuss or abuse of the clutch. During the first climb, which occupied 7 mins., the water temperature rose from 152 to 158 degrees F., ambient being 62 degrees F. The thermostat would barely be opened at the temperature recorded in the cooling system.

I changed places with Kelly after descending Mow Cop, and after a cautious preliminary trial, enjoyed the full performance of the vehicle, on the NewcastleManchester road. I covered four miles in five minutes, which is equal to an average speed of 48 m.p.h. Although visibility was still no better, there was no danger in driving the Foden fast, because the brakes were highly efficient at all speeds. Coaches often travel fast on straight stretches of road, but the Foden, with its cross-braced frame and excellent suspension, can also corner safely at high speed.

The main fuel tank was refilled at the works in readiness for consumption trials. As the chassis was equipped with the high-ratio axle, two tests were made —a non-stop run and a second to simulate inter-urban bus-operating conditions. A 31-mile course was planned for the continuous run, which included town and mainroad work.

Rapid Gear Changing.

Starting from Sandbach, an uneventful journey was made into Middlewich, and the right-angle turn on to the bridge in the town was negotiated in direct drive. The steep hill out of the town enforced the use of an indirect ratio, but the instantaneous acceleration of the two-stroke engine, coupled with the easy gear change, made an extremely rapid change to third gear possible without loss of road speed. This is one of the features of the two-stroke-engined chassis that enables it to negotiate hills in a gear higher than vehicles with the conventional four-stroke engine.

With third gear engaged, the Foden literally roared up the hill, and the sharp turn left to the Warrington road was made without need to engage a lower ratio. The exhaust note, reverberating between the houses in the narrow streets, approached the volume and tone of a sports-car exhaust. I liked the sound, and although it attracted little attention in Sandbach, many heads were turned as we passed through the more distant towns.

A steady speed of 35 m.p.h. was maintained from Middlewich to Lostock and Mere, but a convoy between Knutsford and Brereton reduced our pace to 20 m.p.h. When in the van of the convoy, I noted that the Foden climbed all gradients in direct drive, whereas the normal coaches and other traffic were forced to a lower ratio.

Branching away from the main road at Brereton, the pace was again increased to 35 m.p.h., to complete the course in 64 mins. This corresponds to an average speed of 29.1 m.p.h. Fuel was carefully measured into the tank to replenish it to the original level, and after compensating for temperature variation, I found that the fuel return was 15.4 m.p.g. An economical result had been expected, but this shows at least 10 per cent. improvement on any figure that I have obtained with -a single-decker chassis.

Speed With Economy.

The second trial, with a 15-sec. stop to every mile, was made over a shorter, circular course, which started from Sandbach and included Middlewich and Holmes Chapel. By judicial timing of stops, delays at the traffic lights were avoided, and I arrived back at the works in 39 mins. As the total distance covered was 161 miles, it will be seen that I did not spare the engine revolutions during the trial. Although the engine was punished to the extreme to attain an average speed of 25 m.p.h., including stops, the economy was almost unimpaired, the fuel return working out to 10.35 m.p.g.

Operating temperatures at the end of this run were: Engine oil, 156 degrees F.; rear-axle lubricant, 132 degrees, and atmosphere, 66 degrees Because of the high gear and load, I used low ratio when moving away from rest during the trials, but as an experiment, employed second gear on level ground. Although the Foden did not jib, I found the acceleration rate to be slower and a tendency for the clutch to slip. • For this reason, the short-performance trials were made using first, second and third ratios, the maximum speed in third gear being 33 m p.h. This procedure of using only indirect ratios to reach 30 m.p.h. produced abnormally fast acceleration from rest to 20 m.p.h. in 12.5 secs., with an additional 10.1 secs. to reach 30 m.p.h.

By comparison, the top-gear performance was disappointing, but considering the conditions of the trial and the light shell, which represents the flywheel, the 61 secs, taken to reach 30 mph. from a moving start is not altogether unsatisfactory. With experience of the two-stroke engine and the easy-change gearbox, no service driver would attempt to engage direct drive below 25 m.p.h.

The boost pressare of the brakes has been increased since the Foden passenger chassis was first produced, with the result that the brake efficiency is of a high order. I could not determine the true efficiency, because all level roads in the area had a loose granite-chip surface. Tests from 30 m.p.h. produced a stopping distance of 44 ft., with all wheels locking to show tyre marks for at least 40 ft. Given better conditions, I think the measured stopping distance would be in the region of 30 ft.

The large frictional area of the facings suggests that the braking system should not require frequent attention. Because of the high braking efficiency and frictional area, it is not surprising that the Foden is in demand by operators with vehicles working over the steep gradients in Wales.

Clutch operation is abnormally light and a heavier spring pressure could be applied to the clutch of the twostroke-engined model without unduly increasing the effort required in driving. I was far from fatigued at the end of the trials, because the liveliness of the power unit, coupled with the ease of control, made driving a pleasure. With the high governed speed of the engine and well-matched gear ratios, other vehicles on the road can be overtaken with added safety. For example, third gear was employed to reach 33 m,p.h. before engaging direct drive while accelerating from rest during the fuelconsumption trials.

Although the two-stroke-engined chassis costs slightly more than the standard machine, the higher price may be offset within the first few months by the saving in fuel cost. Traffic superintendents will soon find that, labour permitting, schedule times can be cut.