NEW DAIMLER CHASSIS

Page 88

Page 89

If you've noticed an error in this article please click here to report it so we can fix it.

with Special Transmission

DURING the past few weeks we ,have made several references to the developments in connection with the Daimler transmission system and to the latest type of low-loading chassis, designated the CM. We are now able to make the first announcement of the standardized combination of the • CG6 chassis and the transmission system, in two models, designated 0H6. We have already given an exclusive report of its performance as a double-saloon bus.

Generally speaking, details of these chassis are identical, except for the main-frame members, and certain other items which must vary, in accordance with the purpose for which the chassis is ordered, i.e., as a base for a single-deck or doublesaloon bus. The illustrations are of. the double-deck type, which was the model inspected by us. The singledeck chassis will vary as regards the rear end of the frame and the wheelbase; it is 15 ft. 6iins, for double-deck work, or 17 ft. for single-deck coach or bus duty.

Chassis Prices.

In standard form the Daimler Co., Ltd.,'Coventry, is marketing the new CH6 type at 11,275 for the chassis for double-deck work, or £1,250 for single-deck service; the corresponding prices of the CG6, which is the same chassis but with a single-plate clutch and a four-speed slidingpinion gearbox, are 11,175 and £1,150 respectively.

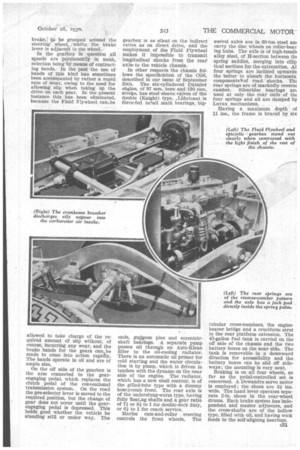

Dealing first with the new transmission -system, we find that the Fluid Flywheel includes the startergear ring, whilst at the back of this is the aluminium casting serving as the housing for the driven rotor ; this rotor is coupled to the primary propeller shaft, which has Simms-Jurid link-type universal joints at each em!. The Fluid Flywheel consists of c30 The controls of the CH6 chassis are closely grouped around the steering column. Note the position of the pre. selector lever to the right of the column and below the wheel ; on the opposite side is the horn switch.

the driving and driven rotors, the casing being filled with special oil through plugs in the rear face. An oil-retaining bearing is employed at the centre to prevent lubricant exuding. It is necessary to replenish the oil in the Fluid Flywheel only about every 10,000 miles. The loss is due more to evaporation than to actual use,. .

Gearbox Mounting.

The epicyclic gearbox, which is of the Wilson type, is three-point suspended in the frame, amidships. The single point at the front consists of an arm anchored to a lug on a tubular cross-member. of -the -frame, mounted below .the level of the Maim, shaft. Atthe.rear two split clamps pass around an arched, tubular cross-member, above the level of the final propeller shaft, which has at both ends Hardy-Spicer mechanical joints of the fully enclosed type. Both the cross-members carrying the gearbox are offset in order to permit the propeller shaft to run in a straight line from the engine to the rear-axle pot, which is on the near side.

On the near side of the gearbox is an arm coupled to the pre-selector control, mounted directly below the steering wheel on the off side. The various positions for the four forward gears, neutral and reverse, are clearly indicated, and motion of the control can be checked by touch, sothat it is not necessary to look down at the lever when driving, neither is it necessary to remove the hand from the steering wheel. Ciue'ef the advantages of this transmission system is that it enables all I:piingl controls, exclusive of the hand brake,' to be grouped around the steering wheel, whilst the brake lever is adjacent to the wheel.

In the gearbox in question all speeds are permanently in mesh, selection being by means of contracting bands. In the past the use of bands of this kind has sometimes been accompanied by rather a rapid rate of wear, owing to the need for allowing slip when taking up the drive on each gear. In the present instance this . has been eliminated, because the Fluid Flywheel, can,be allowed to take charge of the required amount of slip without, of course, incurring any wear, and the brake bands for the gears can,be made to come into action rapidly. The bands operate in oil and are Of ample size.

On the off side of the gearbox is the arm connected tothe gearengaging pedal, which replaces the clutch pedal of the conventional transmission system. On the road the pre-selector lever is moved to the required position, but the change of gear does not occur until the gearengaging pedal is depressed. This holds good whether the vehicle be standing still or under way. The

gearbox is as silent on the indirect ratios as on direct drive, and the employment of the Fluid Flywheel makes it impossible to transmit longitudinal shocks from the rear axle., to the vehicle chassis.

In other respects the chassis follows the specification of the C06, described in our issue of September. 30th. The six-cylindered Daimler engine, of 97 mm. bore and 130 mm. stroke, has steel sleeve valves of the double (Knight) type. .Thbricant is force-fed to!all main bearings, big

ends, gudgeon pins and eccentricshaft bearings. A separate pump passes oil through an Auto-Klean filter to the oil-cooling radiator. There is an automatic oil primer for cold starting and the water circulation is by pump, which is driven in tandem with the dynamo on the near side of the engine. The radiator, which has a new shell contour, is of the gilled-tube type with a dummy honeycomb front. The rear axle is of the underslung-worm type, having fully float.ng shafts and a gear ratio of 7i or Si to 1 for double-deck duty, or 6i to 1 for coach service.

/axles cam-and-roller steering controls the front wheels. The swivel axles are in 60-ton steel am carry the disc wheels_ on roller-bear lag hubs. The axle is of high-tensil( alloy steel, of H-Section between tin Spring saddles, merging into ellip tical sections for the extremities. Al four springs are inclined upwards the better to absorb the horizonta components Vof road shocks. Thc rear springs are of markedly revers€ camber. Silentbloc bearings art used at only the rear ends of VIE four springs and all are damped by Luvax mechanisms.

Having a maximum depth of 11 ins., the frame is braced by six

tubular cross-members, the engine. bearer bridge and a cruciform strut in the rear platform extension. The 45-gallon fuel tank is carried on the off side of the chassis and the two battery boxes on the near side. The tank is removable in a downward direction for accessibility and the battery boxes can be slid off sideways ; the mounting is very neat.

Braking is on all four wheels, so far as the pedal-controlled set is concerned. A Dewandre servo motor is employed ; the shoes are 33 ins. wide. The hand lever operates separate 2-in, shoes in the rear-wheel drums. Each brake system has independent and master adjusters, and the cross-shafts are of the hollow type, filled with oil, and having wick feeds to the self-aligning bearings.