A CLEVER EMERGENCY REPAIR.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

One of Several Useful Ideas Contributed by Our Driver and Mechanic Readers.

RATHER AN ingenious get-out from 11.. an awkward situation is related in a letter from ".H.A..H.," of London, W.C. 1, and he is awarded the-15s. prize this week. He drives a Ford—one of those which have been converted to ordinary magneto ignition. The magneto itself is mounted on a Steel plate, which is bolted to the crankcase, and is chain-driven, suitable provision being

made, by means of elongated bolt-holes in the magneto bracket (the steel plate aforesaid) for adjustment of the chain tension. Of course, the inevitable happened, and at night, too—the chain, broke. The first, intimation was the sudden stoppage of the engine, to the tune of a peculiar rattle under the bonnet, succeeded by dead silence.

Examination revealed the fact that the chain had not only broken, but had also departed, there being no undershield to prevent its going. However, a search along the roadtbrought it to light again, and an inspection,of it showed one sideplate to be hors de combat. There were no spares in the tool-box, and the adjustment in the plate for the magneto was already as far over in the requisite direction as it could go. Fortunately, in the search for spares, a piece of 10-gauge iron wire had come to light. This our correspondent bent U shaped, giving the " 1,1" as sharp corners as he dared, and making the legs exactly as far apart as the units in the chain. This piece of wire, employed as shown in the accompanying sketch, was then made to do duty instead of the broken plate, being pushed. into place, Use legs of the TT through the rivet-holes of the chain, from the side in which the broken plate had been. The protruding ends of the wire were bent•outwarels, as shown, and trimmed op. The magneto was then retimed—not a long operation, as both sprockets Were marked—the engine started, and away he went. The wire is still in Use.

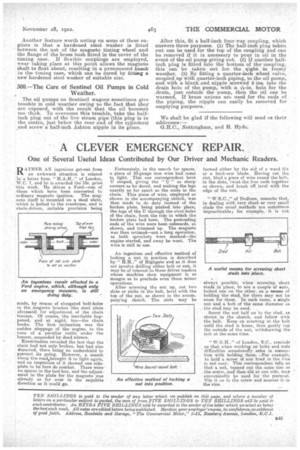

An ingenious and effective method of locking a nut in position is described by." HR.." of Highgate and as it does not involve drilling either bolt or nut, it may be of interest to those driver readers whose machine shoo equipment is so meagre as to preclude even these minor operations. After screwing the nut up, cut two slots or nicks in the bolt, level with the top of the nut, as shown in the accompanying sketch. The slots may be formed either by the aid of a ward file or a hack-saw blade. Having cut the slot, bind a piece of wire round the bolt, in the slots, twist the free ends tog_ether as shown, and break off level with the edge of the nut.

" W.E.C.," of Dedham, remarks that., in dealing with very short er very small studs the 'usual methods are sometimes impracticable; fox example, it. is not

always possible, when screwing short studs in place, to use a couple of nuts, locked one on the other, as a means of holding the stud, for there may not be room for them. In such cases, a single nut and a bolt of the same diameter as the stud may be used.

Screw the not half on to the stud, as shown in the sketch, and follow with the bolt. Keep od screwing at the bolt until the stud is home, then gently tap the outside of the nut, withdrawing the bolt at the same time.

" W.G.1-1„" of London, EC., reminds us that when working on bolts and nuts difficulties occasionally arise in connection with holding: them. -For example, to hold a screw of any Ithid in the vice is not easy.. This correspondent tells us that a nut, tapped out the seine use as the screw, and then slit at one side, may conveniently be used for the purpose. Slip it on to the screw and squeeze it in the vice.