THE LATEST IN GULLY EMPTIERS.

Page 19

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

A New Machine With Many Interesting Features Emanating from the Works of a Prominent Undertype Steam-wagon Manufacturer.

THERE are few, if any, municipal requirements that cannot be efficiently and economically met by the modern motor vehicle, and many special jobs which, a few years back, were considered to be beyond the useful sphere of

• the mechanical road motor, are nc.w being performed by it with most satisfactory results. One can, cite as a test case the work of gully emptying. Previously undertaken by a horse-drawn vehicle of the open type, into which the gully slop was emptied following its extraction in scoops by men walking alongside of the vehicle, this work is now being generally carried out by local. authorities in a much more hygienic manner by the petrol-propelled or steam-driven motor vehicle.

The latest addition to the list of vehicles of this type -is one which emanates from the works of Sentinel .Waggon Works (1:92O), Ltd., Shrewsbury. As might be expected, the chassis itself embodies the well-tried charac-. teristics of the company's steam wagons which have built up a remarkable reputation in many parts of the world.; -but, so far as the gully-emptying mechanism i is concerned, t possesses one or two outstanding features which distinguish it . frosts other vehicles of similar type.

In the .work of gully emptying, two. problems have to be solved. Firstly, the design -of the sludge inlet valve must he such that it will not become easily

• cheked by tree twigs or bits. of broken bottles when the slop is being extracted ; the valve Mao must be protected from . the scouring action of the sludge. Secondly, after collection, the 'sludge must he readily removable -from the wagon tank. The second is not such a simple operation as it sounds, for by the time the sludge is ready to be clumped, the constituent solid matter has set to

the consistency of clay. The manner in which these difficulties and others associated With the problem have been overcome will be readily observed in the following description of the new .Sentinel wagon.

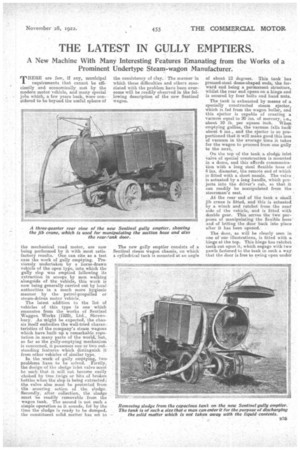

The new gully emptier consists of a Sentinel Steam wagon chassis, on which a cylindrical tank is mounted at an angle

of about 12 degrees. This tank has pressed-steel dome-shaped ends, the forward end being a permanent structure, whilst the rear end opens on a hinge and is secured by four bolts and hand nuts.

The tank is exhausted by means of a specially constructed steam ejector, which as fed from the wagon boiler, and this ejector is capable of creating a vacuum equal to 20 ins, of mercury, i.e., about 10 lb. per square inch. When emptying gullies, the vacuum falls, back about 6 ins., and the ejector is so proportioned that it will make good this loss of vacuum in the average time it takes for the wagon to proceed from one gully to the next.

On the top of the tank. a sludge; inlet valve of special 'construction is mounted in a dome, and this affords communication with a long steel flexible hose of 4 ins, diameter, the remote end of which is fitted with a short nozzle. The valve is actuated by a long handle, which projects into the driver's cab, so that it can readily be manipulated from the steersman's seat.

At the rear end of the tank a sinall jib crane is fitted, and this is actuated hy a winch and ratchet from the neat side of the vehicle, and is fitted with double gear. This serves the two pur• poses of manipulating the flexible hose and of letting the door back into place 'after it has been opened. • The door, as will be clearly seen in one of our illustrations, is fitted with a hinge at the top. This hinge has ratchet teeth cut upon it, which engage with two pawls fastened to the tank in such a way that the door is free to swing .open under the weight of the liquid inside the tank when the bolts are slacked off and the vacuum released, but it cannot 'return until the pawls are freed by a chain which is provided for the purpose. . if they are required, two list rectangular sealing tanks for sealing up the gullies after they have been emptied, can be disposed at the sides of the cylindrical tank, and an alternative design makes preNision for these tanks and the sludge tank to be fitted with sprinklers, so that, if needed, the wagon may be used to serve a dual purpose. It is ohinns that, if the sealing tanks are not required, a sludge tank of slightly larger dimensions can be fitted on the chassis.

The method of manipulating the gully emptier is not without interest. The rear door being closed and the bolts screwed down hard, the ejector is started until the vacuum gauge, which can be readily seen by the driver, •regis ters a 20-in. vacuum. The wagon is then ready for work. After arrival at a gully the flexible hose, which is supported in a fastening on the side of the frame, is manipulated by means of the jib crane until its nozzle is at the bottom of the gully. The main -valve is then opened and the gully almost immediately emptied.'

When the tank is full, the wagon is taken to the sludge dump, and, the vacuum being maintained, the door bolts are slacked off. and swung clear. The main sludge valve is then opened, and this breaks the vacuum inside the tank, and the weight 'of the liquid portion of the sludge immediately swings the door open. After the liquid is discharged the solid matter can be easily raked hut, if necessary, by a man inside the tank, as shown in one of our illustrations.

So simple is the process that the whole operation of clearing the tank can be executed in five minutes, which is much shorter than the time required in some other designs which rely upon a small manhole for emptying purposes. The ejector is of a high efficiency pattern, and it will easily permit of 12 to 18 gullies being emptied in an hour. The vacuum is sufficient to lift the sludge 15 feet.

The simple joint between the rear door and the end of the tank has been specially designed tie be air and water tight, .and .to -maintain this tightness over a long period .of 'working. The main sludge valve is also very neat and simple, and has an easily renewable face and seat.

The company fully realize that municipal authorities may not be able to keep the vehicle wholly and solely employed on one task, and they are therefore prepared to make the gully-cleaning tanks and gear' So that they can be readily de-tached from the chassis, which can then be put to other uses.

'The new Sentinel gully emptier has undoubtedly been designed with a thorough and intimate knowledge of municipal requirements in connection . with the extraction and removal of sludge from street and other gullies, and the design of the vehicle is typical of the products which hail from the Shrewsbury works, in which simplicity of construction and quality of workmanship are dominant characteristics.

It should be mentioned that the main features of the new vehicle are being protected by patent.