The Darracq Cab or Light-Van Chassis.

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

A Well made Machine, of Which Many are Now in Use.

The demand for light commercial. motor chassis has led to the productioA of many excellent designs, and daily we see increasing numbers of this type of machine, more particularly when fitted with cab bodies, on the London streets. It is, moreover, quite a rare occurrence to find such a vehicle " hung up" on the roadside for any cause other than tire troubles. The designs have been evolved after many years' experience in pleasure-car design and construction, coupled with a thorough knowledge of the requirements of such a vehicle, when used commercially. One vehicle of this class ran throughout the re. cent trials withou t he loss

of a single mark, and it gained the gold medal for its class. Other vehicles, of the same capacity, also put up good records and, of these, A3 and A4, the two Darracq delivery vans, are particularly interesting from the constructional point of view, as they are good examples of a practice introduced by

De Dion-Bouton, namely, the combination of the change-speed gear-box with the back axle. A representative of this journal took an opportunity, recently, of calling at the Darracq works at Suresnes, in order to examine more carefully this make of chassis, and to observe the conditions and materials under which, and of which, the various component parts are made.

The same type of chassis is employed for both cab and light delivery van work and it may be lilted with either a two or a four-cylinder engine. Both the engines are of compact design and the cylinders of each are cast en bloc and are finished on special machines which bore the two or four cylinders at the same time. By this means, assisted by the employment of numerous jigs and special fixtures during the course of manufacture, perfect inter_ changeability of parts is ensured. The necessity for such a system was demonstrated by an incident in the Trials.

The water-jacket on the engine of A4 was accidenta.ly cracked,through screwing a plug in too tightly. Repair of the cracked cylinder was impossible and, therefore, a new, finished, cylinder casting was telegraphed for from Paris ; this, when received at T-Iungerford, was fitted to the otherwise disabled car, and the vehicle was able to continue its journey within the Club's specified time. The repair, or rather replacement, was a very smart piece of work, but it is very certain that, had not

such a perfect system of jigs, limitgauges, and detail inspection, been in operation at the company's works at Suresnes, the feat would have been impossible. We reproduce a photograph of the four-cylinder engine on page 299, and on this page is a view of part of the company's engine-testing house. The smooth running of this make of internal-combustion motor is clearly demonstrated by the photograph ; the room was particularly dark, and an exposure of three minutes was necessary ; during the whole of that time, the third engine from the right was running on petrol, and for part of the time the second engine from the right was being driven off the belt (in order to bed in its parts) previous to running under its own power. The sharpness of the picture will show that there was no undue vibration.

The company's arrangements for bedding and testing its engines are most complete. The testing-room is divided into separate bays, in each of which a different size of engine is tested. All the necessary water and exhaust piping is permanently fixed, and the connections for each motor are, therefore, easily and quickly • made. The clutch shaft is connected, by means of a special coupling, to a pulley shaft and, by that means, the engine may be driven by belt or may be used to drive other engines in the same way. A reference to the illustration of the engine will show the compact and simple nature of its arrangement. The 14toh.p. model has four cylinders, each

of which are 85mm. in diameter, with a piston-stroke of toomm. The twocylinder engine develops its to-12h.p., on cylinders which are toomtn, in diameter; its pistons have a stroke equal to 120111M. All the valves are mechanically operated, and high-tension magnetos are fitted.

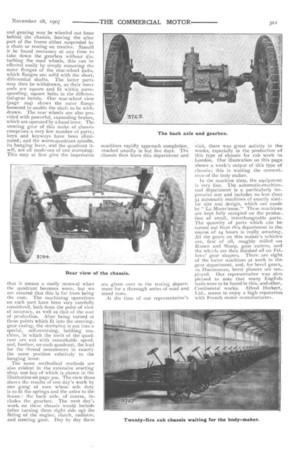

A cone clutch transmits the power from the engine to the gear-box, through a long, propeller shaft, as may be seen in our illustration of the chassis;

it will be noted also that the gearbox_ is mounted directly over the fixed back axle, and that its main shaft and lay shaft are both parallel to the axle. The shaft is, of course, driven from the propeller shaft through bevel-gearing. The illustration of the gearbox will make its arrangement quite clear to our readers. The box provides for three changes of gear, the top speed being a direct drive, which is effected by causing the jaws (A and B) to engage with corresponding recesses within the face of the gear wheel (C).

The shafts (D and E) transmit the motion to the road wheels, and, on the squared end of the lay shaft (F), a footoperated, brake drum is mounted. The differential gear is enclosed within the casing (G). The ease with which the back axle and the gearbox may be removed from the chassis, is well shown in the back-axle illustration. By merely uncoupling the brake and change-speed operating rods, and the side-spring strap-bolts, the Whole axle and gearing may be wheeled out from behind the chassis, leaving the after part of the frame either suspended by a chain or resting on trestles. Should it be found necessary at any time to take down the gearbox without disturbing the road wheels, this can be effected easily by simply removing the outer flanges of the rear-wheel hubs, which flanges are solid with the short, differential shafts-. The latter parts may then be withdrawn, as their inner ends are square and fit within corresponding, square holes in the differential-gear bevels. Our rear-wheel view (page 294) shows the outer flange loosened to enable the shaft to be withdrawn. The rear wheels are also provided with powerful, expanding brakes, which are operated by a hand lever. The steering gear of this make of chassis comprises a very low number of parts; keys and keyways have been eliminated; and the worm-quadrant spindle, its hanging lever, and the quadrant itself, are all made out of one stamping. This may at first give the impression that it means a costly renewal when the quadrant becomes worn, but we are assured that this is far from being the case. The machining operations on each part have been very carefully considered, both from the point of view of accuracy, as well as that of the cost of production. After being turned at those points which fit into the steeringgear casing, the stamping is put into a special, self-reversing, hobbing machine, in which the teeth of the quadrant are cut with remarkable speed, and, further, on each quadrant, the lead for the thread commences in exactly the same position relatively to the hanging lever.

The same methodical methods are also evident in the extensive erecting shop, one bay of which is shown in the illustration on page soo. The view there shows the results of one day's work by one gang of men whose sole duty is to fit the springs and the axles to the frame : the back axle, of course, includes the gearbox. The next day's work on these chassis would include (after turning them right side up) the fitting of the engine, clutch, radiator, and steering gear. Day by day these machines rapidly approach completion, reached usually in but five days. The chassis then leave this department and are given over to the testing department for a thorough series of road and stand tests.

At the time of our representative's

visit, there was great activity in the works, especially in the production of this type of chassis for cab work in London. Our illustration on this page shows a week's output of this type of chassis; this is waiting the conveni(MCC of the body maker.

In the machine shop, the equipment is very fine. The automatic-machinetool department is a particularly impressive one and includes no less than sq. automatic machines of exactly similar size and design, which are made by " La Macerienne." These machines. are kept fully occupied on the production of small, interchangeable parts._ The quantity of parts -which can beturned out from this department in the course of 24 hours is really amazing_ All the gears on this maker's vehicles are, first of all, roughly milled on Brown and Sharp, gear cutters, and the wheels are then finished off on Fellows' gear shapers. There are eight of the latter machines at work in thee gear department, and, for bevel gears,. to Ducommun, bevel planers are em-. ploy-ed. Our representative was also. pleased to note that many English tools were to be found in this, and other. Continental works. Alfred Herbert, Ltd., seems to enjoy a high reputation with French motor manufacturers..