A Thoroughbred Fire Engine

Page 78

Page 79

Page 80

Page 83

If you've noticed an error in this article please click here to report it so we can fix it.

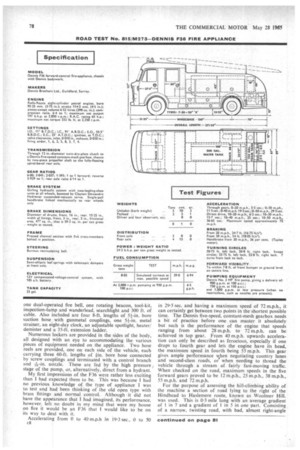

ROAD TEST: Dennis F36 Fire Appliance

IT is not often that a commercial vehicle offered for test to the technical Press produces anything more than a factual repop of the performance and perhaps a few complaints about inaccessibility of the oil filter or the starter motor, or that the diff, cannot be lifted without removing half the body. But this is not so in the case of the Dennis F36 fire engine which I tested recently. This machine would, I am sure, surprise quite a number of my motoring correspondent colleagues in Fleet Street with its sheer thoroughbred qualities.

Powered by the Rolls-Royce B81 eight-cylinder-inline petrol engine, and endowed with handling qualities that have for long been a feature of Dennis vehicles, it can be driven with a degree of dash that hitherto I have thought was reserved for the Astons and the Jaguars of this world. The machine waS destined for the Colombo Fire Brigade, and I would have taken the greatest pleasure in delivering it personally, by road, to its new owners. such was the delight I experienced during the time I had the vehicle for test.

It takes some time to get used to the idea that fuel consumption and first cost are of secondary consideration when placing an order for a fire appliance, these two items having for a long time been a ruling factor for anyone dealing with goods vehicle purchasing. But it is surprising to see the extra quality which can be obtained for a slightly higher cost, and it appears that fire brigades all over the world find that quality pays.

Designed to meet the needs of modern times, the F36 is, apart from being extremely fast, a strictly functional piece of equipment. Fitted with the Dennis No. 3 HP fire pump, it is capable of delivering water at rates of up to 1.000 g.p.m. at low pressures, and 750 g.p.m. at pressures up

to 150 p.s.i. The test vehicle was put through its paces at the Dennis pumptesting station in the Guildford works, where I asked that it should work on a lift of 10 ft. from the shaft of the pump. From scratch, water was lifted the 10 ft. in exactly 5 sec. up the 5+ in. suction hose. Once the pump had hold of the water it was passible to shut oft and hold the head, so avoiding the need for repriming.

The test pump, running at 2,000 r.p.m., was churning out 930 g.p.m at 100 p.s.i., and a fuel consumption test carried out at this time produced a figure of 6.5 g.p.h. Dennis engineers told me that there was no reason why the unit could not run continuously, so long as it was provided with petrol and oil. The full-power pt.-o. is capable of accepting this kind of treatment, and the heat-exchanger which is mounted below the bottom tank of the radiator provides ample cooling for the engine. A by-pass on the pumping equipment provides the water for this unit.

To deal quickly with small outbreaks of fire. and with those requiring special treatment, the F36 is fitted with a water tank and a foam tank of 400 gal. and 120 gal. capacity respectively. These are known as the "first aid " equipment and allow the appliance, once at the scene of a fire, to start operating almost at once.

A result of many years' development, the 3 HP pump is of the centrifugal type and has all the wet components manufactured in gunmetal. The mainshaft is of toughened steel, sleeved in bronze where in contact with water, and is provided with a mechanical, self-adjusting, drip-free gland. Composition bushes are used to eliminate the need for adjustment at the scene of a fire.

The pump is built as a self-contained unit on a subframe, and mounted on the chassis by flexible-rubber mountings. It is provided with a control panel containing the engine-throttle control, pump-primer control, pumppressure gauge, pump-compound gauge, pump rev, counter and lubrication paints for the pump shaft. Priming is by a twin-cylinder exhauster powered by an auxiliary drive taken from the main pump drive. The drive is taken from the 0.-0 through a one-piece propeller shaft. Connections between the water and foam tanks and the pump are by armoured flexible-hose; this is' to facilitate movement of the units on their flexible-rubber mountings.

Composite construction is used for the bodywork. All frames are in best-quality ash, and boarding is in either Utile or resin-bonded plywood. The exterior of the body can be panelled in unpainted, embossed aluminium, or finished in plain aluminium, painted to customers' requirements.

The test vehicle was fitted with double doors at both sides and a bench seat extending the full width of the vehicle for the crew members. The driving seat was of the fully adjustable type, and the one for the officer was of similar design but non-adjustable. As the applianee tested was going to Colombo, it was fitted with a divided windscreen which had the, top halves arranged to open. The European version is fitted with

.one-piece screen-and, I would think, provides slightly better vision, especially when operating in rain. .The, screen wipers on the vehicle tested were somewhat 'restricted in length because of the half-screens and, of course, there was a centre pillar. Nevertheless, vision from the driving seat was extremely good and I did not find any blind areas, despite the fact that 1 piloted the machine at a high speed around a circuit that I did not know and which was twisty, to say the least.

Standard equipment on the appliance includes. statutory lighting and flashing indicators, reversing light, twin wipers, F7 one dual-operated fire bell, one rotating beacon, tool-kit. inspection-lamp and wanderlead. searchlight and 300 ft. of cable. Also included are four 8-ft. lengths of 5+-in, bore suction hose with gunmetal couplings, one 54-in, metal strainer, an eight-day clock, an adjustable spotlight, heater/ demister and a 35-ft. extension ladder.

Numerous lockers are provided in the sides of the body, all designed with an eye to accommodating the various pieces of equipment needed on the appliance. Two hose reels are provided, one on each side of the vehicle, each carrying three 60-ft. lengths of fin, bore hose connected by screw couplings and terminated with a control branch and nozzle. These are fed by the high pressure stage of the pump, or, alternatively, direct from a hydrant.

My first impressions of the F36 were rather less exciting than I had expected them to be. This was because I had no previous knowledge of the type of appliance I was to test and had been thinking of the old open type with brass fittings and normal control. Although it did not have the appearance that I had imagined, its performance, howcver, left no doubt in my mind that were my house on fire it would he an F36 that I would like to be on its way to deal with it.

Accelerating from 0 to 40 m.p.h in 19-3 sec., 0 to 50 1:8 in 29.5 sec. and having a maximum speed of 72 m.p.h., it can certainly get between two points in the shortest possible time. The Dennis five-speed, constant-mesh gearbox needs a bit of practice before one can master it absolutely but such is the performance of the engine that speeds ranging from about 28 m.p.h. to 72 m.p.h. can be achieved in top gear. From 40 m.p.h. upwards acceleration can only be described as ferocious, especially if one drops to fourth gear and lets the engine have its head, the maximum speed in fourth being 55 m.p.h. This gear gives ample performance when negotiating country lanes and second-class roads, or when needing to thread the vehicle through a stream of fairly fast-moving traffic. When checked on the road, maximum speeds in the five forward gears proved to be 12 m.p.h., 25 m.p.h., 38 m.p.h., 55 m.p.h. and 72 m.p.h.

For the purpose of assessing the hill-climbing ability of the machine a section of road lying to the right of the Hindhead to Haslemere route, known as Woolmer Hill. was used. This is 0-3 mile long with an average gradient of I in 7 and a gradient of 1 in 5 in one part. Consisting of a narrow, twisting road, with bad, almost right-angle bends, it proved that the handling of the machine in what can be described only as adverse conditions was as good as on any other type of going.

The hill was climbed twice, first to determine the speed with which it would be surmounted and secondly to check the gear in which it was possible to start. The first run proved that the hill was no match for the machine, which climbed from bottom to top in 1 min. 8,5 sec. The lowest gear engaged was third and the minimum speed recorded was 13 m.p.h. With an ambient temperature of 5'C. (42"F.) the engine coolant temperature was 68•C. (156'F.) at the bottom of the hill. At the end of the climb this had risen only VC. to 77'C. (172F.).

Stop-and-start tests on the steepest part of the hill proved that although it was not possible to move off in second gear, a smooth take-off in first gear was no problem, leaving plenty of power in hand. At this point I would have liked to see the addition of a clutch-stop, as I am convinced that it would have been possible to change into second gear quite easily if _the clutch could have been stopped from spinning. • • Dennis engineers told me that the twin-plate clutch with which this vehicle is fitted settles very nicely once it has run for a few hundred miles. I must say that the one on the test vehicle proved to be a bit fierce and was inclined to drag a bit when engaging gears from a standstill.

Turning the vehicle round and 'facing down the hill, I 'coasted down at about 25 m.p.h. with a fairly severe. continuous application of the footbrake. In a cloud of smoke a maximum pressure stop at the bottom of the hill produced a TapleY-rneter reading of 70 per cent from a speed of 20 m.p.h., a 'reduction of. 21per cent over the figures .obtained with the brakes ;Cold. The handbrake proved capable of holding the vehicle with ease facing both up and down the hill and did, in fact, bring the vehicle to ,a standstill when rolling down backwards without assistance from the footbrake.

When carrying out the brake tests it was immediately evident that Dennis know how to produce a well balanced systern.' Onall the stops made. both from 20 m.p.h. and from 30 m.p.h., the behaviour of the. machine was perfect, with wheels locking for only a couple of feet at the very end of each stop: this was an identical distance for both front and rear wheels.

When doing the simulated turn-out later I noticed that it was possible to make light checking applications of the brakes quickly and accurately • without having any effect on the directional stability of the steering. This contributed in no small way to my feeling of being completely at home within the first couple of miles of the highspeed test.

A figure of 36 per cent was achieved with the handbrake only, and this was the only time that any severe wheel 'locking was experienced. The overall figures were considerably better than any obtained in previous tests of this type of vehicle by The Commercial 11.4 ot,».. being 16.75 ft.'s' from 20 m.p.h. and 18-05 ftis2 from 30 m.p.h.

As ,a normal fuel consumption test isof little value with a vehicle of this type, a simulated turn-out and highspeed run over a 25-niile route was carried out. The route used was from Milford on A3 to Puttenham on the Hogsback, thence to Farnham on to A287, via Churl, to Hindhead and return to Milford on A3. As I was not familiar with the route it was necessary to take extensive precautions when approaching corners and narrow parts; also I was held up badly. by traffic on the Ffogsback. Even so. 1 found it possible to put up an. average speed of 39 m.p.h. over the route, and returned a fuel consumption Of 6-94 m.p.g.

The fact that this was done in what I consider to be perfect safety says a lot for the handling qualities of the vehicle and of the confidence that it instils in those driving it. I consider that these are the most important features which a vehicle of this nature can have, as it must be remembered that a fire-engine driver never travels far enough to become absolutely conversant with his machine. Informed circles tell me that the average mileage covered is in the region of 1,000 a year, hardly enough to really "get with it

Tractable and silent

General characteristics of the Rolls-Royce B 81 engine are excellent tractability in top gear, absolute 'silence mechanically and what would appear to be complete, reliability. Fitted with dual-ignition circuits, it is unlikely that the machine will not start when required—and at the first attempt. The cooling system includes an immersion heater and,a thermostatically-eontrolled by-pass circulation to ensure rapid warm-up or easy starting from a warmedup condition.

The engine has a nine-bearing crankshaft with copperlead-indium bearings and is fitted with chromium-plated top piston rings. Many of the components of the eightcylinder engine are identical with those used in the smaller six-cylinder version —a distinct advantage to brigades running both types. A feature of the carburation is that it allows the engine to develop .full power immediately after starting.

From a maintenance point of view, the F36 presents no problems. There is plenty of room around the engine for routine attention, and traps in the floor allow access to the gearbox and clutch assemblies. The pumping unit can be removed complete and the p.t.-o.—which is likely to be the most hard-worked component on the mechanical side of the outfit—can be removed in a few minutes. Dennis Bros. say that vacuum-over-hydraulic brakes are specified for a majority of fire appliances, including this one. The reason for this is simple—although not often thought about. A vehicle with vacuum brakes and a petrol engine builds vacuum almost immediately the engine is started and can be driven away with the least possible delay --very important when going to a fire.

The standard practice when supplying a fire appliance is to provide all equipment from the water to the delivery connection. In this form, and including all the necessary fittings, the approximate cost oF the Dennis F16 is £5.500