DOCK HAI! ING— Bristol Fashion

Page 50

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

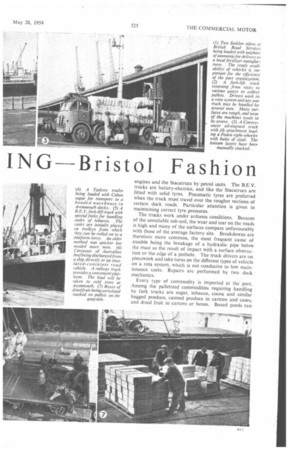

In the Forefront of Users of Modern Handling Systems, the Port of Bristol has Reduced Costs and Looks Forward to the Introduction of More Ambitious Developments

IN September, 1953, the Port of Bristol Authority introduced mechanical handling by tractor-trailer units for inter-warehouse movements, to operate in conjunction with a fleet of 18 fork-lift trucks. It is now claimed that there is no comparable system at any other port in the country.

The organization of the port is planned to allow a high percentage of imported goods to be off-loaded on to road vehicles or rail wagons direct from the ship, and in this connection ample quay space is a valuable feature of the dock layout. .

A large amount of warehousing is, however, inevitable. Many types of goods must be sorted and examined, and warehousing for lengthy periods is often necessitated by Jack of storage space elsewhere. The trailer units are particularly useful when it becomes necessary for goods to be transferred from one transit shed to another with the minimum of delay, and when weather uncertainties cause difficulties which increase the amount of handling required.

It has already been shown that the system reduces the overall cost of inter-warehouse and some quay-towarehouse movements by almost a third, which is relatively a slightly higher saving than the gain afforded by the fork trucks in the short-distance transport and loading of various goods in the warehouses and on the quayside. Before the articulated trailers were employed, the goods were moved longer distances in the port by lorry, electric truck or rail wagon, and this required a much larger labour force.

Political Factors

Before dealing in greater detail with the organization of transport at the dock, it is pertinent to mention two political factors which have a bearing on its efficiency. One is that the wider use of mechanical-handling equipment in ports now receives the general approval of the workers' representatives, and there is agreement on the general introduction of economical handling processes such as those successfully adopted in Bristol. The other is anxiety felt by members of the dock staff regarding the facilities which private hauliers will offer when denationalization has become effective.

A full-time docks depot superintendent is employed by British Road Services and he controls about 80 per cent, of the 2,500 road vehicles which visit, the port daily. He is' fully versed in dock procedure and well known to all the •steVedores and °other personnel With whom he must co-operate:: n16 At daily meetings with port representatives, • the stowage plans of incoming vessels are studied, and an unloading schedule is estimated based on the position of the goods in the hold. man emergency, the superintendent can obtain vehicles from depots within a radius of 50 miles from Avonmouth, and although there is no guarantee that the lorries will be of the most suitable type, there is never any doubt that their total capacity will be adequate.

The vehicles used for inter-warehouse work comprise three Bedford petrol-engined tractors and 10 Taskers 8-ton trailers. The fork trucks are of Conveyancer, Stacatruc and B.E.V. manufacture with capacities of 4,000 lb., the Conveyancer trucks being powered by oil

engines and the Stacatrucs by petrol units. The B.E.V. trucks are battery-electrics, and like the Stacatrucs are fitted with solid tyres. Pneumatic tyres are preferred when the truck must travel over the rougher sections of certain dock roads. Particular attention is given to maintaining correct tyre pressures.

The trucks work under arduous conditions. Because of the unsuitable sub-soil, the wear and tear on the roads is high and many of the surfaces compare unfavourably with those of the average factory site. Breakdowns are therefore more common, the most frequent cause of trouble being the breakage of a hydraulic pipe below the mast as the result of impact with a surface obstruction or the edge of a pothole. The truck drivers are on piecework and take turns on the different types of vehicle on a rota system, which is not conducive to low maintenance costs. Repairs are performed by two dock mechanics.

Every type of commodity is imported at the port. Among the palletized commodities requiring handling by fork trucks are sugar, tobacco, cocoa and similar bagged produce, canned produce in cartons and cases, and dried fruit in cartons or boxes. Boxed goods can readily be moved and stacked by fork truck without any manual handling, but bagged produce is sometimes difficult or uneconomic to handle by this means. The labour saving in respect of cased goods is well over 33i per cent., whilst the overall saving on bagged material is much less.

The condition of bags is an important factor. If a loose material, such as grain or powder, is contained in bags which are worn, perished or damaged, the lower bags in a load may split or disintegrate. As a consequence, material may be lost and the reduction in support may cause the upper bags to overbalance. -Bagged material which sets hard into an irregular shape cannot be safely handled when placed on open pallets because the load is unstable. When bags are stored in the warehouse for a long period, they are stacked by means of a portable elevator to a much greater height than could be achieved by fork truck. The space required for temporary storage in the sheds is, however, greatly reduced in practice when the bags or containers are handled by truck.

Simplified Problem

Produce in cartons can readily be moved on pallets, given that the cartons are sufficiently robust to withstand a reasonably heavy load. When suitable cartons are used, such a method of packing provides the best form for mechanical handling. In this connection, an obvious assumption is that, where similar methods are used extensively in the factory, the problem of handling at the docks is also simplified.

'After experiments had been made with all types and sizes of pallet, it was decided to adopt the standard 6 ft. by 4 ft. wood pallet. This enables an economic load to be carried, and wood construction is preferred because the stillages can be easily repaired.

For handling tobacco in casks or tierces, specially shaped forks with inclined support faces are fitted to the trucks. The casks are initially loaded on a movable platform from which they can easily be rolled on to the lorry. Before, this method was introduced, the casks were rolled over the side of the vehicle and the job was completed in half the time, but mechanical handling has reduced the labour force from six, excluding the vehicle driver, to one. It has also increased the storage capacity of the shed—an important factor in cost and convenience.

In some instances, fork trucks are employed to add a second layer to a load, the first layer of which has been loaded by hand. For example, the first layer of sisal bates is manhandled on to the vehicle from the warehouse platform, and the second layer is placed into position by a fork truck with a jib attachment and a grab hook. Bales of fibre are also loaded in his way.

Experiments with vehicle loading from the side by fork truck were discontinued when it was found that loading with two trucks simultaneously was necessary to avoid tilting the platform so severely that the forks were clamped in the pallet and could not be withdrawn. Practically all the goods carried by the tractor-trailer units are loaded and stocked on pallets, the trailers being suitable for both side and end loading.

Special Vehicle?

A pallet is often placed on the end of a delivery vehicle for the goods to be stacked by hand_ It is considered that a vehicle specially designed for pallets would serve a useful purpose, and that trucks could be modified to obviate "fork sticking" when goods are loaded on the slant.

Some boxed or cartoned produce is loaded on pallets in the hold of the boat and is picked up by a fork truck on the quay without further manual handling, use being made of a cargo tray under the pallet, which provides for safe handling by the crane. When the boxes are immediately removed from the pallet after being transferred to the shed or warehouse, they are loaded on the cargo tray in the hold and the tray is dropped on the pallet after removal by the crane to the quay. A sling attachment is sometimes used for lifting the pallet Transporting goods on pallets from the factory to the user or vendor is regarded as a promising possibility. The time for unloading from the holds could be substantially reduced and both ex-ship deliveries and warehouse movements would be facilitated. The development of suitable road and rail services (including the return of pallets) would, however, be necessary to implement the scheme.