MEETING TRANSPORT PR(

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

3LEMS WITH CONTAINERS

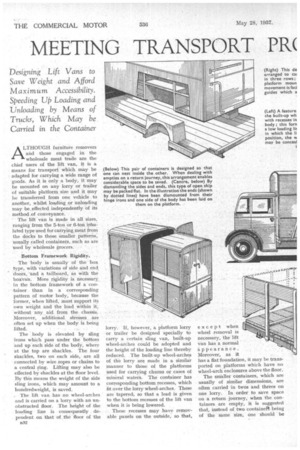

Designing Lift Vans to Save Weight and Afford Maximum Accessibility. Speeding UP Loading and Unloading by Means of Trucks, Which May be Carried in the Container -Economizing Space When Carrying Empties by Making Containers Collapsible, Enabling the Components to be Piled Up on the Lorry. A Useful Suggestion for Mick Skips ALTHOUGH furniture removers and those engaged in the wholesale meat trade are the chief users of the lift van, it is a means for transport which may be adapted for carrying a wide range of goods. As it is only a body, it may be mounted on any lorry or trailer of suitable platform size and it may be transferred from one vehicle to another, whilst loading or unloading may be.effected independently of its method of conveyance.

The lift -van is made in all sizes, ranging from the 5-ton or 6-ton irftlated type used for carrying meat from the docks to those smaller patterns, usually called containers, such as are used by wholesale grocers.

Bottom Framework Rigidity.

The 'body is usually of the box type, with variations of side and end 'doors, -and a tailboard, as with the boivan. More rigidity is necessary in the bottom framework of a container than in a corresponding pattern of motor body, because the former, when lifted, must support its own weight and the load within it, 'without any aid from the chassis. Moreover, additional stresses are often set up when the body is being lifted.

The body is elevated by sling irons which pass under the bottom and up'each side of the bodY, where at the top are shackles. The four shackles, two on each side, are all • connected by wire ropes or chains to a central ring. Lifting may also be -eflected by shackles at the floor level. By this means the weight of the side sling irons, which may amount to a hundredweight, is saved.

. The lift van has no wheel-arches and is carded on a lorry with an unobstructed floor. The height of the loading line is consequently dependent on that of the floor of the B.32

lorry. If, however, a platform lorry or trailer be designed specially to carry a certain sling van, built-up wheel-arches could be adopted and the height of the loading line thereby reduced. The built-up wheel-arches of the lorry are made in a similar manner to those of the platforms used for carrying churns or cases of min-era' waters. The container has corresponding bottom recesses, which fit over the lorry wheel-arches. These are tapered, so that a lead is given to the bottom recesses of the lift van when it is being lowered.

These recesses may have removable panels on the outside: so that, except when wheel removal is necessary, the lift van has a normal appearance. Moreover, as it has a flat foundation, it may be transported on platforms which have no wheel-arch enclosures above the floor.

The smaller containers, which are usually of similar dimensions, are often carried in twos and threes on one lorry. In order to save space on a return journey, when the containers are empty, it is suggested that, instead of two containeft being of the same size, one should be

sma

it to be placed completely inside the larger one. would be about 6 ins. smaller in each direction.

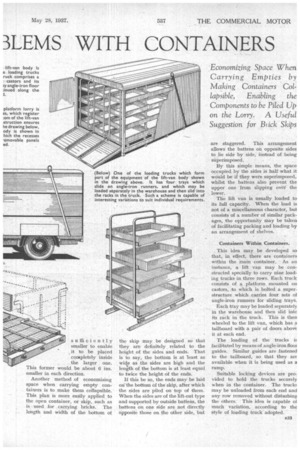

Another method of economizing space when carrying empty containers is to make them collapsible. This plan is more easily applied to the open container, or skip, such as is used for carrying bricks. The length and width of the bottom of

the skip may be designed so that they are definitely . related to the height of the sides and ends. That is to say, the bottom is at least as wide as the sides are high and the length of the bottom is at least equal to twice the height of the ends.

If this be So, the ends may be laid clithe bottom of the skip, after which the sides are piled on top of them. When the sides are of the lift-out type and supported by outside battens, the battens on one side are not directly opposite those on the other side, but are staggered. This arrangement allows the battens on opposite sides to lie side by side; instead of being superimposed.

By this simple means, the space occupied by the sides is half what it would be if they were superimposed, whilst the battens also prevent the upper one from slipping over the lower.

The lift van is usually loaded to its full capacity. When the load is not of a miscellaneous character, but consists of a number of similar packages, the opportunity may be taken of facilitating packing and loading by an arrangement of shelves.

Containers Within Containers.

This idea may be developed so that, in effect, there are containers within the main container. As an instance, a lift van may be constructed specially to carry nine loading trucks in three rows. Each truck consists of a platform mounted on castors, to which is bolted a superstructure which carries four sets of angle-iron runners for sliding trays.

Each tray may be loaded separately in the warehouse and then slid into its rack in the truck. This is then wheeled to the lift van, which has a tailboard with a pair of doors, above it at each end.

The loading of the trucks iE facilitated by means of angle-iron foot guides. Similar guides are fastened to the tailboard, so that they are available when it is being used as a ramp.

Suitable locking devices are provided to hold the trucks securely when in the container. The trucks may be unloaded from each end and any row removed without disturbing the others. This idea is capable of much variation, according to the style of loading truck adopted.