New diesels fro old

Page 104

Page 105

If you've noticed an error in this article please click here to report it so we can fix it.

SPADE has a niche in small to medium unit reconditioning and follows up with after-sales service by Piper Cherokee

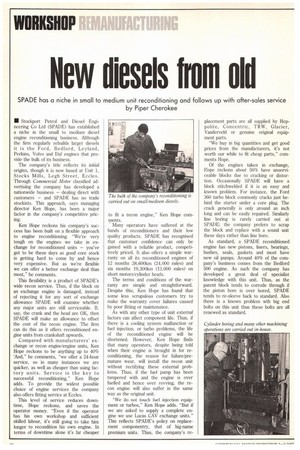

• Stockport Petrol and Diesel Engineering Co Ltd (SPADE) has established a niche in the small to medium diesel engine reconditioning business. Although the firm regularly rebuilds larger diesels it is the Ford, Bedford, Leyland, Perkins, Volvo and Daf engines that provide the bulk of its business.

The company's title reflects its initial origins, though it is now based at Unit 1, Stocks Mills, Legh Street, Eccles. Through Commercial Motor classified advertising the company has developed a nationwide business — dealing direct with customers — and SPADE has no trade stockists. This approach, says managing director Ken Hope, has been a major factor in the company's competitive pricing.

Ken Hope reckons his company's success has been built on a flexible approach to engine reconditioning. "We're very tough on the engines we take in exchange for reconditioned units — you've got to be these days as good core stock is getting hard to come by and hence very expensive. But as we're flexible we can offer a better exchange deal than most,'' he comments.

This flexibility is a product of SPADE's wide recon service. Thus, if the block on an exchange engine is damaged, instead of rejecting it for any sort of exchange allowance SPADE will examine whether any major units are still serviceable. If, say, the crank and the head are OK, then SPADE will make an allowance to offset the cost of the recon engine. The firm can do this as it offers reconditioned engine units from crankshaft upwards.

Compared with manufacturers' exchange or recon engine/engine units, Ken Hope reckons to be anything up to 40% 'And," he comments, "we offer a 24-hour service, so in many instances we are quicker, as well as cheaper than using factory units. Service is the key to successful reconditioning," Ken Hope adds. To provide the widest possible choice of engine services the company also offers fitting service at Eccles.

This level of service reduces downtime, Hope reckons, and saves the operator money. "Even if the operator has his own workshop and sufficient skilled labour, it's still going to take him Longer to recondition his own engine. In terms of downtime alone it's far cheaper to fit a recon engine," Ken Hope comments.

Many operators have suffered at the hands of reconditioners and their low quality products. SPADE has recognised that customer confidence can only be gained with a reliable product, competitively priced. It also offers a simple warranty on all its reconditioned engines of 12 months 38,600km (24,000 miles) and six months 19,300km (12,000 miles) on short motors/cylinder heads.

The terms and conditions of the warranty are simple and straightforward. Despite this, Ken Hope has found that some less scrupulous customers try to make the warranty cover failures caused by poor fitting or maintenance.

As with any other type of unit external factors can affect component life. Thus, if there is a cooling system malfunction or fuel injection, or turbo problems, the life of the reconditioned engine will be shortened. However, Ken Hope finds that many operators, despite being told when their engine is brought in for reconditioning, the reason for failure/premature wear, will install the recon unit without rectifying these external problems. Thus, if the fuel pump has been tampered with and the engine is over fuelled and hence over revving, the recon engine will also suffer in the same way as the original unit.

"We do not touch fuel injection equipment or turbos," Ken Hope adds. "But if we are asked to supply a complete engine we use Lucas CAV exchange units." This reflects SPADE's policy on replacement componentry, that of big-name premium units. Thus, the company's re placement parts are all supplied by Heppolite, Concentric, TRW, Glacier, Vanderveld or genuine original equipment parts.

"We buy in big quantities and get good prices from the manufacturers, it's not worth our while to fit cheap parts," comments Hope.

Of the engines taken in exchange, Hope reckons about 50% have unserviceable blocks due to cracking or distortion. Occasionally SPADE will have a block stitchwelded if it is an easy and known problem. For instance, the Ford 360 turbo block commonly cracks just behind the starter under a core plug. The crack generally is only around an inch long and can be easily repaired. Similarly line boring is rarely carried out at SPADE; the company prefers to scrap the block and replace with a sound unit these days rather than line bore.

As standard, a SPADE reconditioned engine has new pistons, liners, bearings, bushes, seals, gaskets and most have new oil pumps. Around 40% of the company's business comes from the Bedford 500 engine. As such the company has developed a great deal of specialist knowledge with this unit. Thus, as the parent block tends to corrode through if the piston bore is over bored, SPADE tends to re-sleeve back to standard. Also there is a known problem wth big end bolts on this unit thus these bolts are all renewed as standard.

The company's output of engines alone has now reached around 14 units per week; added to this is a large number of reconditioned crankshafts, heads and the like. And SPADE's products also benefit from an after-sales service that few other companies in the reconditioning business can offer. As a keen private flyer, long-distance spares deliveries, service call out and the like are sometimes flown by Hope in his own Piper Cherokee 140 aeroplane. This has proved to be especially useful with one long-standing customer in a very remote part of the country.