Motorway Building Mechanized

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

MANY kinds of modern labour-saving plant are being used by John Laing and Son, Ltd., and associated contractors, on the construction of the London-Birmingham motorway, work on which was started on. Monday. Nearly 70 miles of road are scheduled to be completed in 19 months. this means that a mile of double carriageway road must be built every nine days and that a bridge must be completed every three days.

The southern end of the motorway, known as the St. Albans by-pass, will start at a point on the North Orbital Road (A405), south of St. Albans and will join the main trunk of the motorway at Luton. At intervals of about 12 miles along the road there will be service areas on both sides of the motorway with fuelling, parking and catering facilities. Cost of the project is £20m.

When work is at its peak, 3,700 men and over '1,000 major pieces of roadmaking equipment will be employed. Two aircraft will be operated for supervision and for bringing spares for machinery. More than 8m. gallons of fuel will be needed to keep the machinery running and some 4m. sq. yd. of roadway will be laid.'

There will be 150 bridges and viaducts over the rivers Nene,Great Onse and Ousel. More than 90 per cent, of the motorway will be of . a gradient flatter than 1 in 50, and achieving this will involve shifting 14m. cu. yd. of earth.

The surface of the road will be of asphalt which will be laid on top of tarmacadam. Tarmac Civil Engineering, Ltd., will be responsible for 'building 12 miles of the St. Albans by-pass.

Aid for Exports Speaking at the inauguration of the work, Mr. Harold Watkinson, Minister of Transport, said that the motorway would stand comparison with any road scheme anywhere else in the world. Better transport facilities would improve the ability of the export industries to compeei in foreign markets. New roads wolud make a real contribution to the policy of beating inflation.

The British Road Federation sent a telegram to the Minister congratulating him and his staff for bringing the first stages of the motorway to the verge of reality. When the road came into use next year the country would gain immediate and increasing benefits.

Shell-Mex and B.P.. Ltd., and the Mobil Oil Co., Ltd., have given details of how they will supply fuel and lubricants to the contractors. Shell are responsible for the fuelling arrangements on three of the sections of the road and Mobil for one. All sections will be built simultaneously.

Shell recently built a modern depot at Northampton and will use it as the parent supply point, sub-depots having been set up at Chalton Cross, Newport Pacmall and Watford. Teams of drivers will work shifts to ensure that fuelling vehicles are always available.

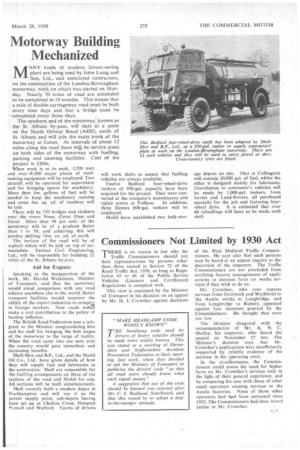

Twelve Bedford fout-wheel-drive tankers of 950-gal. capacity have been acquired for the project. They were converted at the company's maintenance and

repair centre at Fulham. In addition, three Dennis 800-gal. tankers will be employed.

Mobil have established two bulk-stor

age depots on site. That at Collingtree will contain 20,000 gal. of fuel, whilst the other is designed mainly for lubricants. Distribution to contractor's vehicles will be made by 1,000-gal. tankers, 3-ton lorries and Land-Rovers, all purchased specially for the job and featuring fourwheel drive. It is estimated that over 60 refuellings will have to be made each shift.