DROPFRAIVIE TO TAKE THE CAKE

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

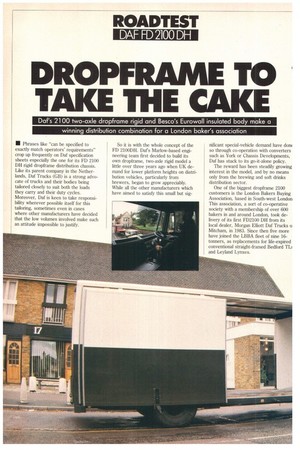

Daf's 2100 two-axle dropframe rigid and Besco's Eurowall insulated body make a winning distribution combination for a London baker's association • Phrases like "can be specified to exactly match operators' requirements" crop up frequently on Daf specification sheets especially the one for its FD 2100 DH rigid dropframe distribution chassis. Like its parent company in the Netherlands, Daf Trucks (GB) is a strong advocate of trucks and their bodies being tailored closely to suit both the loads they carry and their duty cycles. Moreover, Daf is keen to take responsibility wherever possible itself for this tailoring, sometimes even in cases where other manufacturers have decided that the low volumes involved make such an attitude impossible to justify. So it is with the whole concept of the FD 2100DH. Daes Marlow-based engineering team first decided to build its own dropframe, two-axle rigid model a little over three years ago when UK demand for lower platform heights on distribution vehicles, particularly from brewers, began to grow appreciably. While all the other manufacturers which have aimed to satisfy this small but sig

nificant special-vehicle demand have dorm so through co-operation with converters such as York or Chassis Developments, Daf has stuck to its go-it-alone policy.

The reward has been steadily growing interest in the model, and by no means only from the brewing and soft drinks distribution sector.

One of the biggest dropframe 2100 customers is the London Bakers Buying Association, based in South-west London This association, a sort of co-operative society with a membership of over 600 bakers in and around London, took delivery of its first FD2100 DH from its local dealer, Morgan Elliott Daf Trucks o Mitcham, in 1983. Since then five more have joined the LBBA fleet of nine 16tonners, as replacements for life-expired conventional straight-framed Bedford TL5 and Leyland Lynxes. LBBA transport manager, David itrcher, is well pleased with the dropbrae Dafs. He says that, compared with e old TLs and Lynxes with tail lifts, the wet platform height and easier load ;cess of the Dafs can save each driver ) to two hours a day on distribution runs up to 20 drops within a radius of 96km 10 miles) of the warehouse.

DAD ACCESS I The 2100 we tested is one of two hich joined the fleet in April this year. ke all LBBA Dafs delivered since 1984, is fitted with a Besco Eurowall body, e detail specification of which has 7olved through close co-operation beteen Curcher, Peter Ross, sales man!er at Morgan Elliott and Besco Bodies Northampton.

The first LBBA FD 2100 was fitted ith a Southfields curtain-sided body, hich both Curcher and Ross say has .oved much less than satisfactory for is application. Curcher's main complaints e of the wheels on which the curtains a) in a top track, wearing out at an arming rate, and of the curtains themlves being prone to jamming by loose ads moving sideways.

Our test load on this occasion was 10 tonnes of Flemings baker's fondant, shrink wrapped on to 10 pallets so it was unlikely to move. A more normal load for an LBBA truck is 10 pallets of mixed, loosely wrapped commodities such as salt, sugar, yeast and flour, or any other produce a modern baker requires.

There is a high risk of part of such a load moving sideways. With the Eurowall body this causes the driver no difficulty as the walls pivot down and outwards from their top runners when they are opened. We experienced more difficulty at first when closing the two sliding doors each side, not because of a bulging load, but because with three cam locks per door operated by a central over-centre lever locking mechanism, each door has to be precisely positioned before it can be locked shut.

However, the more we used the doors the less trouble we had, and the more we liked them. They give quick and easy access to any part of the load;0000 a prime requirement of any distributio driver — and they offer good safety and security, through a stout integral lock on each door. The four, spring-loaded rods fitted to the cant rails that are designed to allow the doors to be held in any operio position when the vehicle is parked on a gradient, is a useful refinement.

The platform height of the front and rear pallet-carrying sections of the body is only 0.55m from the ground, which puts the top of a full pallet at a comfortable unloading height. Despite the intrusion, for one metre behind the front bulkhead, of the sloping propeller shaft tunnel cover, six 1200 x 1000mm pallets will fit quite neatly into it. Two more go on the saddle over the drive axle, and two more at the rear. Timber wedges fixed to the outer edges of the 17mm non-slip Wisamant ply floor tilt each pallet towards the centre of the vehicle and help prevent them from moving in transit. Really loose loads in the main section are restrained by three pairs of load restraint straps.

A small refrigerated compartment behind the cab, (where the frame and body floor step up and where, on the offside, the Daf fuel tank and air reservoirs have been re-sited), is used for carrying items such as frozen pies and pastry which require temperatures down to -20°C.

In anticipation of growing future demand from its members for more chilled products — such as fat, which would be carried in the main body sections — the LBBA specifies insulation for the doors and roof of the whole body. The conversion to enable the body to carry chilled goods would be straighforward, involving simply fitting a fan to the front bulkhead to blow refrigerated air down the complete body length. The roof-mounted, engine-driven refrigeration unit, with mains electric stand-by, has capacity in hand for this.

MANOEUVRABILITY

• A Hi-tomer with the voluminous carrying capacity of this Daf — 10 pallets plus the refrigerated compartment — might be expected to have poor ma

noeuvrability because of its overall length. Our turning circle tests and distribution route operational trial confirmed that manoeuvrability is in fact one of its strong points, and highlighted the advantage of the relatively short wheelbase of 5.25m.

This is the shortest wheelbase offered by Daf on this model.

PAYLOAD • As for payload in weight terms, again the FD2100 DH does better than might be expected. The FD chassis cab, surprisingly, is considerably lighter (about 220kg model for model) than an equivalent conventional FA model. Our test vehicle's payload is a very healthy full 10tonnes, and that despite its tyres being the relatively heavy tubed type with three-piece wheels.

The 10.00 x 20 tyres were specified instead of the more common tubeless and slightly wider IIR 22.5 type in order to satisfy conflicting requirements of legal maximum width and floor width peculiar to a drop frame truck. The rear track clearly has to be narrow enough to allow the rear doors to be closed and not exceed the 2.5m maximum-width limit. With IIR 22.5 tyres this cannot be done when the floor width is enough to accommodate two 1200mm-wide pallets side by side.

PERFORMANCE • When a manufacturer is prepared to take a truck straight out of service at very short notice for us to test, as Daf did in this case, it speaks volumes for the manufacturer's confidence in the model. This 2100 lived up fully to the high expectations of it, and despite having only about 6,000km on its tachograph at the start of the test, it produced no nasty surprises in fuel consumption or any other performance criterion. The Dafs fuel consumption of 26.4 lit/1001cm (10.7mpg) over our new, 177km distribution route between MIRA and Hungerford in Berkshire must be judged good, although so far we have only one other 16-tonner, the Volvo FL6 (CM, April 5), with which to compare it. The Volvo averaged 28.5 lit/1001cm (9.9mpg) over this route which, with seven simulated drops and a lot of stop/ start work, is designed to bring fuel consumption down below the figures ot established Welsh route gives us.

The histograms on page 49 show how the Daf compares with three recently tested rivals over this route. One remarkable aspect of the Daf s performance is the consistency of the fuel consumption on motorway and A road. The 2100 is tel from being ideally geared for motorway work, its highest available 5.72:1 rear 2ud itio leading to the engine having to work : very close to its governed maximum .400rpm at a road speed of 96km/h iOmph).

Compared with many more powerful iodern 16-tonners the 2100 is sluggish, Phich is reflected most markedly in our xeleration and hill-climb time results. [owever, the normally aspirated 8.25re engine, which in turbocharged and large-cooled form powers some Daf 38)nners, clearly is lightly stressed at 16 aines GVW.

The engine's relatively low torque, and ie way the torque falls off quickly in rpical naturally-aspirated diesel fashion leans that the splitter on the ZF gearbox lids to be used liberally. Like other 12)eed synchromesh ZF gearboxes we ave used recently, this one had a very zy synchromesh which could easily be 5aten, on third gear. We found the best ay to get a clean shift when moving from ..cond low to third low, the usual sequace when moving off from rest, was to Duble de-clutch as if the gearbox were mistant mesh.

The air-assisted clutch requires a light dal effort, a boon for a vehicle which is equently driven in heavy traffic and on hich the gears have to be used a lot.

amiss

I A rolling road brake test confirmed te subjective impression that this Dafs rakes are first rate. The exhaust brake more impressive than most, too, roviding an effective means of checking )eed on long downhill stretches.

UMMAITY I As a specialist distribution vehicle the D 1200 DH with its Besco Eurowall ady scores highly in all of the important

areas. Some operators may be put off such a specialist vehicle by potential disposal problems, but others, like the LBBA, will value its ability to improve distribution efficiency much more highly than this and other minor disadvantages of relatively high initial cost and the inconvenient propeller shaft intrusion into part of the load space_