Batteries, 4

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

BATTERIES are expensive and any extra care which will prolong their life is well worth while.

Correct installation when the vehicle is new is very import ant. The battery should be easy to reach and inspect because regular attention is required. It should be fitted well away from the exhaust system so that it does not become overheated, but at the same time as close to the starter motor as possible to permit the use of snort cable lengths to avoid excessive voltage drop.

It must not vibrate but the mounting clamps must not be overtightened as this may crack the casing.

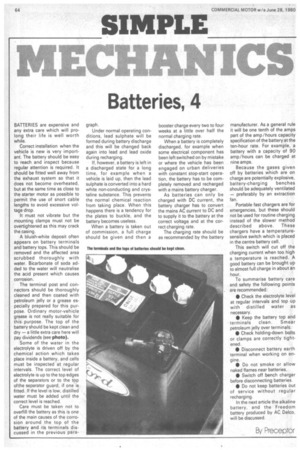

A bluish-white deposit often appears on battery terminals and battery tops. This should be removed and the affected area scrubbed thoroughly with water. Bicarbonate of soda added to the water will neutralise the acid present which causes corrosion.

The terminal post and connectors should be thoroughly cleaned and then coated with petroleum jelly or a grease especially prepared for this pur pose. Ordinary motor-vehicle grease is not really suitable for this purpose. The top of the battery should be kept clean and dry — a little extra care here will pay dividends (seephoto).

Some of the water in the electrolyte is driven off by the chemical action which takes place inside a battery, and cells must be inspected at regular intervals. The correct level of electrolyte is up to the top edges of the separators or to the top of the separator guard, if one is fitted. If the level is low, distilled water must be added until the correct level is reached.

Care must be taken not to overfill the battery as this is one of the main causes of the corrosion around the top of the battery and its terminals discussed in the previous para

graph.

Under normal operating conditions, lead sulphate will be formed during battery discharge and this will be changed back again into lead and lead oxide during recharging.

If, however, a battery is left in a discharged state for a long time, for example when a vehicle is laid up, then the lead sulphate is converted into a hard white non-conducting and crystaline substance. This prevents the normal chemical reaction from taking place. When this happens there is a tendency for the plates to buckle, and the battery becomes useless.

When a battery is taken out of commission, a full charge should be given and then a booster charge every two to four weeks at a little over half the normal charging rate.

When a battery is completely discharged, for example when some electrical component has been left switched on by mistake or where the vehicle has been engaged on urban deliveries with constant stop-start operation, the battery has to be completely removed and recharged with a mains battery charger.

As batteries can only be charged with DC current, the battery charger has to convert the mains AC current to DC and to supply it to the battery at the correct voltage and at the correct charging rate.

The charging rate should be as recommended by the battery manufacturer. As a general rule it will be one tenth of the amps part of the amp/hours capacity specification of the battery at the ten-hour rate. For example, a battery with a capacity of 90 amp/hours can be charged at nine amps.

Because the gases given off by batteries which are on charge are potentially explosive, battery-charging benches should be adequately ventilated — preferably by an extraction fan.

Portable fast chargers are for emergencies, but these should not be used for routine charging instead of the slower method described above. These chargers have a temperaturesensitive switch which is placed in the centre battery cell.

This switch will cut off the charging current when too high a temperature is reached. A good battery can be brought up to almost full charge in about an hour.

To summarise battery care and safety the following points are recommended: • Check the electrolyte level at regular intervals and top up with distilled water as necessary.

• Keep the battery top and terminals clean. Smear petroleum jelly over terminals.

• Check holding-down bolts or clamps are correctly tightened.

• Disconnect battery earth terminal when working on engine. • Do not smoke or allow naked flames near batteries.

• Switch off bench charger before disconnecting batteries.

• Do not keep batteries out of service without regular recharging.

In the next article the alkaline battery, and the Freedom battery produced by AC Delco, will be discussed.

By Preceptor