Van Hool decker has UK potential

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

by CM reporter

THE FIRST fruit of the takeover by Van Hool McArdle Ltd of Coras lompair Eireann's bodybuilding operation in Dublin emerged last week. It is an

all-welded, steel-framed double-deck bus body. Though the new model has been designed with extensive CIE involvement, it will be offered to operators this side of the Irish Sea shortly.

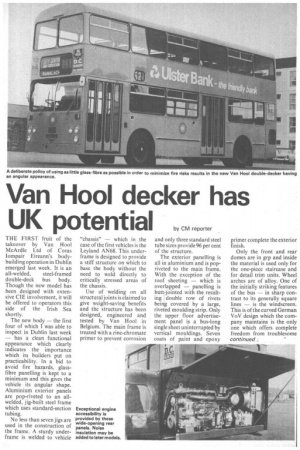

The new body — the first four of which I was able to inspect in Dublin last week — has a clean functional appearance which clearly indicates the importance which its builders put on practicability. In a bid to avoid fire hazards, glassfibre panelling is kept to a minimum and this gives the vehicle its angular shape. Aluminium exterior panels are pop-riveted to an allwelded, jig-built steel frame which uses standard-section tubing.

No less than seven jigs are used in the construction of the frame. A sturdy underframe is welded to vehicle "chassis" — which in the case of the first vehicles is the Leyland AN68, This underframe is designed to provide a stiff structure on which to base the body without the need to weld directly to critically stressed areas of the chassis.

Use of welding on all structural joints is claimed to give weight-saving benefits and the structure has been designed, engineered and tested by Van Hool in Belgium. The main frame is treated with a zinc-chromate primer to prevent corrosion and only three standard steel tube sizes provide 96 per cent of the structure.

The exterior panelling is all in aluminium and is popriveted to the main frame. With the exception of the roof sheeting — which is overlapped — panelling is butt-jointed with the resulting double row of rivets being covered by a large, riveted moulding strip. Only the upper floor advertisement panel is a bus-long single sheet uninterrupted by vertical mouldings. Seven coats of paint and epoxy primer complete the exterior finish.

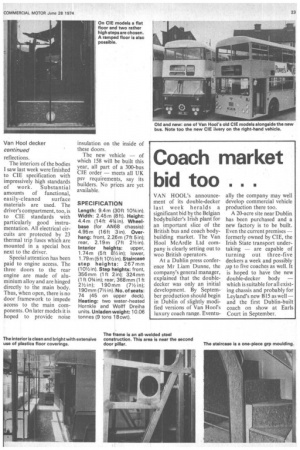

Only the front and rear domes are in grp and inside the material is used only for the one-piece staircase and for detail trim units. Wheel arches are of alloy. One of the initially striking features of the bus — in sharp contrast to its generally square lines — is the windscreen. This is of the curved German VoV design which the company maintains is the only one which offers complete freedom from troublesome continued _ reflections.

The interiors of the bodies I saw last week were finished to CIE specification with impressively high standards of work. Substantial amounts of functional, easily-cleaned surface materials are used. The driver's compartment, too, is to CIE standards with particularly good instrumentation. All electrical circuits are protected by 23 thermal trip fuses which are mounted in a special box next to the driver.

Special attention has been paid to engine access. The three doors to the rear engine are made of aluminium alloy and are hinged directly to the main body. Thus, when open, there is no door framework to impede access to the main components. On later models it is hoped to provide noise insulation on the inside of these doors.

The new vehicle — of which 158 will be built this year, all part of a 300-bus CIE order — meets all UK psv requirements, say its builders. No prices are yet available.

SPECIFICATION

Width: 2.45m 9.4m (10ft 10341n).idth: 2.45 m 8ft). Height: 4.4m (14ft 43 in). Wheelbase (for AN 8 chassis): 4.95m (16ft 3 in). Overhang: front, 2.2 m (7ft 5 in); rear, 2.19m (7ft 21/2 in).

Interior heig ts: upper, 1.74m (5ft 8/2in); lower, 1.79m (5ft 101/n). Staircase step height S: 2 6 7 m m (10½ in). Step haights: front, 356mm (1 ft 2in); 324mm (1ft 03/4in); rear, 368 mm (1 ft 21/2in); 190 mm (71/2in); 190 mm (71/7in). No. of seats: 74 (45 on ipper deck). Heating: two ater-heated Hornkle and Wolff Dreiha units. Unladen weight: 10.06 tonnes (9 tons ' 8 cwt).