Jubilee headquarters for North Western haulier

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

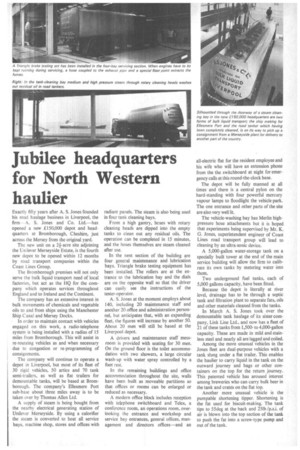

Exactly fifty years after A. S. Jones founded his road haulage business in Liverpool, the firm A. S. Jones and Co. Ltd.—has opened a new £150,000 depot and headquarters at Bromborough, Cheshire, just across the Mersey from the original yard.

The new unit on a 2f acre site adjoining the Unilever Merseyside Estate, is the fourth new depot to be opened within 12 months by road transport companies within the Coast Lines Group.

The Bromborough premises will not only serve the bulk liquid transport need of local factories, but act as the HQ for the company which operates services throughout England and to Ireland and the Continent.

The company has an extensive interest in bulk movements of chemicals and vegetable oils to and from ships using the Manchester Ship Canal and Mersey Docks.

In order to maintain contact with vehicles engaged on this work, a radio-telephone system is being installed with a radius of 15 miles from Bromborough. This will assist in re-routeing vehicles as and when necessary due to congestion or re-programming of consignments.

The company will continue to operate a depot in Liverpool, but most of its fleet of 30 rigid vehicles, 50 artics and 70 tank semi-trailers, as well as flat trailers for demountable tanks, will be based at Bromborough. The company's Ellesmere Port sub-base about three miles away is to be taken over by Thomas Allen Ltd.

A supply of steam is being bought from the nearby electrical generating station of Unilever Merseyside. By using a calorifier the steam is converted to heat all service bays, machine shop, stores and offices with radiant panels. The steam is also being used in four tank cleaning bays.

From a high gantry, hoses with rotary cleaning heads are dipped into the empty tanks to clean out any residual oils. The operation can be completed in 15 minutes, and the hoses themselves are steam cleaned after use.

In the next section of the building are four general maintenance and lubrication bays. Triangle brake testing equipment has been installed. The rollers are at the entrance to the lubrication bay and the dials are on the opposite wall so that the driver can easily see the instructions of the tester-operator.

A. S. Jones at the moment employs about 140, including 20 maintenance staff and another 20 office and administration personnel, but anticipates that, with an expanding fleet, the figures will increase by another 50. About 20 men will still be based at the Liverpool depot.

A drivers and maintenance staff messroom is provided with seating for 30 men. On the ground floor is the toilet accommodation with two showers, a large circular wash-up with water spray controlled by a foot rest.

In the remaining buildings and office accommodation throughout the site, walls have been built as moveable partitions so that offices or rooms can be enlarged or reduced as necessary.

A modern office block includes reception with telephone switchboard and Telex, a conference room, an operations room, overlooking the entrance and workshop and service bay entrances, general offices, management and directors offices—and an all-electric flat for the resident employee and his wife who will have an extension phone from the the switchboard at night for emergency calls at this round-the-clock base.

The depot will be fully manned at all times and there is a central pylon on the hard-standing with four powerful mercury vapour lamps to floodlight the vehicle park. The one entrance and other parts of the site are also very well lit.

The vehicle-washing bay has Merlin highpressure hose attachments but it is hoped that experiments being supervised by Mr. K. G. Jones, superintendent engineer of Coast Lines road transport group will lead to cleaning by an ultra-sonic device.

A 5,000-gallon water-storage tank on a specially built tower at the end of the main service building will allow the firm to calibrate its own tanks by metering water into them.

Two underground fuel tanks, each of 5,000 gallons capacity, have been fitted.

Because the depot is literally at river level, drainage has to be through a septic tank and filtration plant to separate fats, oils and other materials cleaned from the tanks.

In March A. S. Jones took over the demountable tank haulage of its sister company, Link Line Ltd., and now has a fleet of 21 of these tanks from 1,500to 4,000-gallon capacity. These are made in mild and stainless steel and nearly all are lagged and coiled.

Among the more unusual vehicles in the Jones fleet are dual-purpose vehicles with a tank slung under a flat trailer. This enables the haulier to carry liquid in the tank on the outward journey and bags or other containers on the top for the return journey. This patented vehicle has aroused interest• among breweries who can carry bulk beer in the tank and crates on the flat top.

Another more unusual vehicle is the pumpable shortening tipper. Shortening is the fat used for biscuit-making. The tank tips to 55deg at the back and 25113 /p.s.i. of air is blown into the top section of the tank to push the fat into a screw-type pump and out of the tank.