GALORE

Page 69

Page 68

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

Transport Run 761 Vehicles Carrying of Milk, 10.6m. Gal. of Other 44,000 Tons of General Goods a Year ly A. E. Sherlock-Mesher

W1NCANTON, a sleepy Somerset town of 2,537 souls, is the headquarters of one of the biggest and most complex goods-transport networks in the country. It is the centre from which the operations of 761 vehicles, deployed in an area extending from Lancashire and the North Riding to Cornwall and from Kent to Wales, are controlled. Milk and milk products are the staple traffics, but substantial quantities of other commodities are carried. In a year, 173m. gal. of milk, 10.6m. gal. of other liquids and 44,000 tons of general goods are handled.

Wincanton Transport and Engineering Co., Ltd., Station Garage, Wincanton, who had their beginnings in 1925 with a fleet of Dennis and Model-T Ford vehicles, are not only among the largest operators in the kingdom, but have substantial bodybuilding, motor engineering and dairy-engineering interests at Wincanton, Woking, Sherborne and Preston. They maintain the vehicles of the many retail dairies and other companies associated with the Cow and Gate organization, which is the parent body, as well as serving road transport operators generally. Sub-contract work is also undertaken for aircraft manufacturers.

Early Standardization

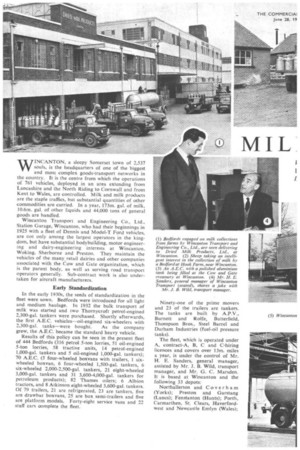

In the early 1930s, the seeds of standardization in the fleet were sown. Bedfords were introduced for all light and medium haulage. In 1932 the bulk transport of milk was started and two Thornycroft petrol-engined 2,300-gal. tankers were purchased. Shortly afterwards, the first A.E.C. vehicles—oil-engined six-wheelers with 2,300-gal, tanks—were bought. As the company grew, the A.E.C. became the standard heavy vehicle.

Results of this policy can be seen in the present fleet of 444 Bedfords (316 petrol 5-ton lorries, 51 oil-engined 5-ton lorries, 58 tractive units, 14 petrol-engined 1,000-gal. tankers and 5 oil-engined 1,000-gal. tankers); 70 A.E.C. (5 four-wheeled boxvans with trailers, 1 sixwheeled boxvan, 6 four-wheeled 1,500-gal. tankers, 6 six-wheeled 2,000-2,500-gal. tankers, 21 eight-wheeled 3,000-gal. tankers and 31 3,600-4,000-gal. tankers for petroleum products); 82 Thames oilers; 6 Albion tractors, and 8 Atkinson eight-wheeled 3,600-gal. tankers. Of 79 trailers, 21 are refrigerated, 23 are tankers, five are drawbar boxvans, 25 are box semi-trailers and five are platform models. Forty-eight service vans and 22 staff cars complete the fleet

Ninety-one of the prime movers and 23 of the trailers are tankers. The tanks are built by A.P.V., Burnett and Rolfe, Butterfield, Thompson Bros., Steel Barrel and Darham Industries (fuel-oil pressure tanks).

The fleet, which is operated under A, contract-A, B, C and C-hiring licences and covers over 13m. miles a year, is under the control of Mr. H. E. Sanders, general manager, assisted by Mr. J. B. Wild, transport manager, and Mr. G. C. Marsden. It is based at Wincanton and the following 33 depots: Northallerton and Co v er ham (Yorks); Preston and Garstang (Lanes); Fenstanton (Hunts); Porth, Carmarthen, St. Clears, Haverfordwest and Newcastle Emlyn (Wales); Sevenoak.s (Kent); London; Bentley, Woking, Guildford and Reigate (Surrey); Chichester (Sussex); Basingstoke (Hants); Newport (Isle of Wight); Sherborne and Beaminster (Dorset); AIler (Som); Torquay, Totnes, Plymouth and Torrington (Devon); Saltash, Lostwithiel, Heston, Camborne, Trenear, Sancreed, and Davidstow (Cornwall).

Transport activities, of which urgency is the keynote, can be divided into five main categories: (1) The collection of milk from farms and delivery to creameries.

(2) Transport of milk in bulk by road tankers to retail or manufacturing points, (3) Delivery of bottled milk from bottling plants to retailers, schools and so on, and the transport of milk products (milk powder, cheese, cream and whey).

(4) Bulk haulage in tankers of petroleum products, soap solutions and cider.

(5) General haulage.

120m. GaL of Milk

Altogether, 120m. gal. of milk are collected annually within a maximum radius of about 40 miles of the various depots. For this work, which occupies a large proportion of the fleet, the company have developed a light-alloy-framed timber-floored platform body with a small upper deck hinged to the headboard and supported on chains. When not required, the shelf can be folded flat against the headboard. Accommodation is provided for 100 10-gal. churns. Outside operators may buy this bodywork as a complete structure or as a kit for home assembly.

Farm milk-collection lorries run to carefully timed schedules to provide the creameries, so far as possible, with a constant flow of supplies. Any vehicle may have up to 40 collecting points on each round and complete two or three rounds a day. Each branch serves the same area throughout the year, but the number of runs and vehicles fluctuates according to milk production, which reaches a peak normally from April to July.

It is, of course, arduous work. Much of the terrain is hard on vehicles, particularly in the North Riding, South Wales, Devon and Cornwall, with a result that fuel consumption is heavy, and maintenance and tyre costs are high.

Tankers, varying in number from 1-26, are based on 15 of the depots. The tanks used for milk are of aluminium or stainless steel and are insulated. These vehicles work 24 hours a day, 365 days a year, mainly on haulage from country creameries to town and city dairies. In the area of which Wincanton is the centre there are four creameries—at Wincanton, Evercreech (eight miles radius from base), Aller (20 miles) and Beaminster (23 miles). A number of tankers serves manufacturing depots and retailers as shunt vehicles for railborne milk.

In some ways tanker operation is the most difficult part of the business and calls for quick thinking by the management. Last-Minute changes in demands may require tankers to be diverted on the road from their original destinations.

At Wincanton, in particular, whence tankers travel daily to the south coast, Home Counties and London, schedules have frequently to be altered at short notice. Drivers have to be summoned in the early hours of the morning and heavy wage costs are incurred. A special worry is the supply of extra vehicles in the summer to meet the large upsurge in the demand for milk at bottling plants near holiday resorts.

Despite all these difficulties, a strict timetable must be observed to ensure that supplies-17m. gal. a year are carried by the tankers—reach the dairies in time for the milk to be processed, bottled and delivered to the consumer. Much night running is entailed.

For the 26 tankers operated from Wincanton, a change-over point has been established at Basingstoke, where local drivers take over the vehicles arriving during the night and in the early morning complete the delivery runs. This half-way house was set up to ensure continuous running and to enable the tankers to be returned to Wincanton the same day after delivering in the London area 110 miles away. Sufficient time must be allowed on each journey for tanks to be sterilized by the dairies.

The gallonage carried by the milk collection and delivery fleet is carefully recorded by the dairies. Milk collected from the farms is " tipped" and weighed immediately the churns leave the vehicle. Each tanker has its own calibration chart and, after loading, a member of the dairy staff dips the tank with a calibrated stick; the measurement and gallonage are recorded on specially designed consignment notes. At the same time, a note is made that the outlets and manholes have been sealed and safety caps placed in position.

At the receiving point, the seals are checked and the tank is again dipped. The measurement and gallonage are then checked against the calibration chart and the consignment note.

Involuntary breakdowns are few, but each branch has equipment for the transhipment of milk from one tank to another on the road.

The delivery of bottled milk, for which specially built insulated boxvans and refrigerated articulated outfits are used, requires equally careful planning. Rounds may cover up to 100 miles, and as loads depend entirely on customers' requirements, part-loads have often to be carried. To ensure economy, stringent schedules have to be observed. The carriage of milk for schools is an important activity, which is subject to seasonal troughs caused by holidays.

Refrigerated Transport

Thirteen vehicles are employed to deal with manufactured milk products. Boxvans haul milk powder in drums, and refrigerated semi-trailers transport butter, cream and cheese, apart from bottled milk. Both the forced-air and eutectic-plate systems of refrigeration are used. A boxvan with 3 in. of Onazote insulation, a double-skinned light-alloy roof and Winget-Dole holdover plates—the type engaged in taking cream from Torrington (Devon) to London—will maintain an internal temperature of 33° F. for at least 36 hours. The forced-air method preserves a similar temperature for about eight hours.

Liquids other than milk (such as petroleum products, soap solutions and cider) are carried in tankers only from Wincanton and Preston. The vehicles hauling petroleum products are painted dark blue to distinguish them clearly in the public mind from the cream and green or polished-aluminium tankers carrying milk. The milk tankers, incidentally, bear plastics advertising banners on their sides.

The single or multi-compartment tanks of vehicles handling petrol, fuel oils and bitumen are of mild steel, and those engaged on spirit transport are lined with either Epikote or aluminium. Except when the load is Spirit, cargoes are discharged by air compressor or by pumps operated from gearbox power take-offs.

Next week I will survey the control, costing and maintenance systems of this great fleet.