Power in Plenty,

Page 56

Page 57

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

kmong the ing andAir-hydratihe Brakes. on Test . ougl:

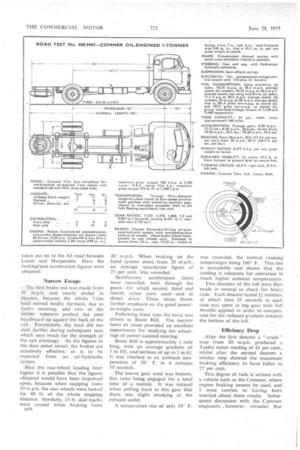

Commer 7-tonner with Power-assisted Steer

-Tares

By John F. Moon,

A.M.I.R.T.E.

ITH power-assisted steering and air-hydraulic brakes, the Commer oilengine,17-tormer, notedSfor its quietness and economy, becomes,: in addition„ one Of the easiest. and .lightest to drive in its class. Short of adding a fully autoT matic gearbo-x; it would he difficult to find -a .7-4onner which is less tiring to handle, both .physically

and Mentally. .

Although 'primarily for limo': distance work, for which it is eminently suited, it is often used by .e(nitractors in agricultural districts. Such jobs as the transport of horses, cattle, sugar-beet and heavy produce generally demand more than a 5-tonner.

The quietness of the Commei is especially important when animals are around, show horses. cattle and pigs being particularly susceptible to change of condition if frightened. A further useful attribute is that the vehicle has a high power-to-weight ratio, hence it can operate in hilly areas without difficulty, gradients ot up to 1 in 4 being manageable. This is important where it is necessary to get the vehicle into the normally inaccessible places at the tops of inclines that seem to abound on some farm estates.

Through the courtesy of Mr. A. E. Moss, of White Cloud Farm, Tring, Herts, I have been able to put a Commer through its paces to prove these points. Mr. Moss is as well known in fanning circles for his prize-winning herd of pigs as are his son. Stirling, in the field of motor racing, and his daughter, Pat, at horse riding.

os ft had been intended that the Commer should do a full day's work at White Cloud Farm, but the only time that the vehicle was available happened to be one of those 'days' when no heavy work needed .doing at the farm.

I had to content .myself, therefore, with performing various odd jobs for which a 7-tonner was not by any means the most suitable vehicle. These did serve to show, however, that no place on the farm was , inaccessible, and that all could be reached with the minimum Of disturbance to livestock and the minimum of effort on the part of the

driver. A near-side rear-view mirror would have been a help when reversing, but the cab glazing provides good direct vision rearwards.

When loading up bales of straw it was .noted that the 18-ft. body made high stacking unnecessary, it being possible to accommodate 20 large bales in each layer.

There is spate behind the cab to build bodies up to 18 ft. 7 in. long, which . makes the chassis suitable for mounting heavy, luxuriously equipped hOrsehoxes and highcapacity cattle bodies. :Helper springs and dampers are available as produclion optional extras to give additional riding comfort—not that the suspension proved at all harsh On the test vehicle, which had plain semi-elliptic springs.

The vehicle tested had a 134 t. 6-in. wheelbase and standard drop-sided body. Optional extras fitted included a Hydrosteer hydraulic servo on the steering gear and a Clayton Dewandre air actuator for the brakes in place of the vacuum servo employed as standard.

Power for the actuator is derived from a single-cylinclered air compressor driVen off one of the engine rocker levers. A three-stage pedal valve is used; this requires up

to 1.0 lb. pressure for initial braking, up to 32 lb for normal braking, and between 55 and 75 Lb, for emergency braking, thereby giving sufficient " fed " for all conditions Of load Or peed.

The Hydrosteer steering servo consists of an engine-driven Pump (with which is combined_ a reservoir); a control valVe integral with the draglink; and a power ram, the cylinder of which is connected to the axle steering arm, whilst the piston is ball-jointed to the chassis frame. The ,steering has a perfectly natural " feel " in the' dead-ahead position, but power assistance takes , effect as soon as the wheel is turned and continues until the wheel is held stationa ry.

There is no time-lag in the system and the power is applied smoothly and safely. Should for any reason the power fail—as when the engine is stopped—steering control remains through the normal direct linkages.

A third optional feature on the test vehicle was a fifth-speed overdrive gear, consisting of an auxiliary helical gear train behind the main gearbox. This gear is engaged by the normal lever, a trigger below the knob preventing accidental engagement. This overdrive reduces engine speed by about 20 per cent. compared with the normal direct-drive top ratio.

As supplied for the normal road part of the test the• Corn met was carrying a test load of iron castings which totalled 7 tons. A distribution check shoved the rear whee1s to be supporting 68.5 per cent, of the gross weight. near to the ideal theoretical ratio.

The chassis had 8.25-20-in. (14-ply) tyres, as opposed to the standard 12-ply equipment, thereby permitting a gross weight of 10 tons 16 cwt., an increase of 12 cwt. over standard.

For the first tests the 7-tonner was taken out on to the A6 road between Luton and Harpenden. Here the brakingland acceleration figures were obtained.

Narrow Escape

--The first brake test was made from 30 m.p.h... and nearly ended in disaster, because the Whole 7-ton load moved bodily forward, due to faulty securing, and two of the

er supports 'pushed the steel headbdard up against the back of the

Cab. tortUnatelY, the load did not shift farther during subsequent tests which says' much for the strength of the cab pressings: As the figtires in the data panel 'reveal, the brakes are extremely effective, as is to he expected' from art 'air-hydraulic system.

Had the rear-wheel loading been higher it is possible that the figures obtained would have been improved upon, because when stopping from 30 m.p.h. the rear wheels were locked for 40 ft. of the whole stopping distance. Similarly, 15-ft. skid marks were caused when braking from 20 m.p.h. When braking on the hand system alone from 20 m.p.h., an average retardation figure of 25 per cent. Was recorded.

Satisfactory acceleration times were recorded, both through the gears-for which second, third and fourth ratios were used-and in direct drive. These times throw further emphasis on the good power to-weight ratio.

Following these tests the lorry was driven to Bison Hill. The narrow lanes en route provided an excellent opportunity for studying the advantage of power-assisted steering.

Bison Hill is approximately mile long, with an average gradient of 1.in 101, and seetionS of up to I. in 6+. It was climbed in an ambient temperature Of 56° F. in 4 'minutes 10 seconds.

• ,The lowest gear used was bottom, this ratio being engaged for a total time of a minute. It was noticed when pulling hard in this gear that there was slight smoking at the exhaust outlet.

A temperature rise of only 10° F. was recorded, the normal running temperatvre being 160° F. This rise is acceptable and shows that -the cooling is adequate for operation in much higher ambient temperatures Two descents of the hill were then made in neutral to check for brake fade. Each descent lasted 21 minutes, of which time 35 seconds in each case was spent in top gear with full throttle applied in order to compensate for the reduced gradient towards the bottom of the hill, Efficiency Drop After the first descent a "crash " stop from 20 m.p.h. produced _a Tapley meter reading of 43 per cent., whilst after the second descent a similar stop showed the maximum braking efficiency to have fallen to 27 per cent.

This degree of fade is serious with a vehicle such as the Commer, where engine braking cannot be used, and I must confess to having been worried about these results. Subsequent discussion with the Commer engineers, however, revealed that

that particular vehicle was fitted with woven facings and that on current chassis Ferodo DM. 8 moulded facings have now been fitted as standard.

These Ferodo facings have been proved to give negligible fade at Bison Hill when fitted to vehicles running at the same gross weight as that of the test lorry.

Fuel-consumption tests were made along an undulating six-mile out-andreturn circuit benfeert Barton and Clophill. Two laden tests were conducted, using a calibrated one-gallon tank. The first run was made without using the overdrive ratio, as would have been the case had this been a standard vehicle without overdrive. This produced an extremely satisfactory consumption rate, particularly in view of the high average speed.

Exceptional Results

A second run was then made with the overdrive engaged wherever possible and this resulted in a 4.3 per cent. improvement irs consumption, despite a slightly higher average

speed. The resulting time •loadmileage factors are exceptional. and fully substantiate the fuel-economy claims of the manufacturers.

During the second day these two consumption tests were repeated with the Commer unladen. This time an improvement of 9.4 per cent, in fuelconsumption rate was recorded with overdrive, showing that the use of overdrive—beneficial as it is with a laden vehicle—is more than twice as effective when running unladen. • From the four figures obtained it can be deduced that operators regu larly running laden in only one direction can expect to average about 20 m.p.g. with a standard vehicle, and over /l m.p.g. when the vehicle is fitted with the overdrive.

My only criticism of the handling qualities of this vehicle relates, once again, to the gear-change mechanism.

Admittedly, this wai 'better on the test vehicle than on some I have tried, but the fault of a weak reversestop spring still exists and, because of the efficiency of the synchromesh mechanism, gear changes are inclined to he stiff.

Visibility is generally good, although by present-day standards the windscreen is not as deep as it might be. As there is no radiator or engine to restrict the depth to which the screen could be taken, it 'seems a pity that the cab design could not be modified to incorporate such an improvement.

The underseat design of the engine successfully removes all of the engine heat and most of its noise from the cab without impairing

accessibility. Indeed, few, forwardcontrol designs have more accessible power units.

Suspension is excellent, even when running unladen.

Most forward control designs incorporate front chimers, but these are not fitted to the • Commer as standard and their absence did not prove detrimental during the test. Steering castor action is retained with the Hydrosteer servo and is present even when unladen.

With overdrive the Comtner 7-ton oiler has a maximum. speed well in excess of 60 m.p.h., at which speeds it continues to handle well in perfect safety. It must be remembered, however, when driving so fast, that engine braking cannot be relied upon and, therefore, brake-facing wear will be rapid if such speeds are used frequently.

Simple Maintenance

There was no time to conduct maintenance tests, but my previous experience with this design shows that maintenance generally is simple. A reasonably comprehensive tool kit is supplied. Access to the engine is given by removing the two seat cushions and the metal seat-box covers. The power unit is then completely exposed for all routine service.

The Com-tier oil-engined 7-ton drop-sider has a basic price of £1,540, with £316 ifs. Od. purchase tax payable in Great Britain. The airhydraulic system costs a total of £65 .12s. 6d. extra, whilst I:100 is charged for providing the Hydrosteer servo.

The optional overdrive is priced at £41 5s. and the 14-ply tyres add £34 to the total price.