Beware 'spurious' replacement parts

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

I/ More than any other factor, water damage caused by condensation is reponsible for brake component deterioration, says Clayton Dewandre/WABCO. To combat annual inspection failure from this cause, and keep trucks on the road, the company's after-market division has introduced a retrofit air drying system.

During the winter, the risk of condensation in the air braking system is considerable as equipment is regularly subjected to dramatic changes in temperature.

All air braker components are vunerable to water and the resultant build up of rust and dirt. Primary corrosion attacks valves, spring brake actuators and pipework in particular. Essential greases and lubricants for efficient valve operation are washed away, resulting in defective parts. Consequently brake efficiency is undermined by excessive air loss, overworked compressors and ultimately complete contamination of the whole system — thus jeopardising vehicle safety, increasing the risk of AVI failure and incurring downtime costs.

In its Winter Preparation package the company provides three methods of tackling the problem of freezing condensation and dirt/oil ingress: alcohol injection equipment, alcohol evaporator equipment; and two single-cylinder drying kits. Recognised, it says, as the most efficient means of removing moisture, oil, dirt and other airborne contaminants, these air dryers — one for governor and one for unloader controlled systems — are now available for retrofit. The kits comprise an air dryer, complete with thermostatically controlled heater element operating between 7° and 29°C; a purge reservoir which, being separate, allows more air to be on the vehicle than do integral ones. Also included, as standard for the first time, is a silencer unit for air noise suppression; and to complete the kit there is a reservoir mounting bracket together with a five-metre heater power cable.

A key feature of these dryers is the incorporation of a screw-on "throw-away" desiccant cartridge to reduce maintenance cost and downtime. This desiccant cartridge has proved highly popular among operators. Being small and compact, the dryer is remarkably quick and easy to fit. Installation instructions and details of pipework fitting combinations that may be required are included in the kit.

The air dryers can be fitted as part of Clayton Dewandre/WABCO's Winter Pre paration Package which features condensor drain valves, automatic drain valves, tilt drain valves, drain taps, stopcocks and test points to cater for all the servicing and replacement needs of operators, facing the combined effects of salt, grit and extreme temperatures in the forthcoming winter.

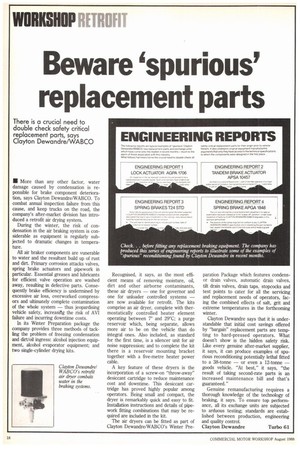

Clayton Dewandre says that it is understandable that initial cost savings offered by "bargain" replacement parts are tempting to hard-pressed operators. What doesn't show is the hidden safety risk. Like every genuine after-market supplier, it says, it can produce examples of spurious reconditioning potentially lethal fitted to a 38-tonne — or even a 12-tonne — goods vehicle. "At best," it says, "the result of taking second-rate parts is an increased maintenance bill and that's guaranteed."

Genuine remanufacturing requires a thorough knowledge of the technology of braking, it says. To ensure top performance, all its exchange units are subjected to arduous testing; standards are established between production, engineering and quality control.

Clayton Dewandre Turbo 61