Time is the vital factor

Page 81

Page 82

Page 83

Page 84

If you've noticed an error in this article please click here to report it so we can fix it.

rfact that time is money has general application to trans-. ptErt operation. But in the movement of perishable produce and foodstuff this factor is of special importance. Here time is money in the sense that delivery to markets must be made on time day-in and day-out to avoid an otherwise real loss in the value of the load. But, additionally, because such traffic does not constitute a luxury trade, operating costs per unit delivered must be low.

In an age when the expression "the bigger the better" has come to be accepted as & foregone conclusion in an economic sense, it is reassuring to those who doubt the validity of the precept to examine the operational success of a business which has expanded by doing the reverse. In effect, this has been the indirect result of putting first things first, namely the maintenance of a distribution system that persistently ensures delivery of perishable produce in fresh condition.

The company is Superior International Ltd., of Great Yarmouth. As part of the same group, an associated company is based in Holland from where local produce is shipped through the port of Scheveningen.

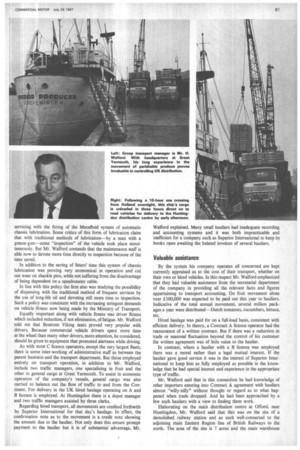

To find out more about the reasons for a policy of operating smaller vehicles at a time when new regulations allow bigger vehicles, I discussed this unusual trend with the group transport manager of Superior International, Mr. H. Watford, at his headquarters in Great Yarmouth.

Briefly outlining the growth of the organization, as a background to its current road transport requirements, Mr. Watford said that as recently as 1957 the present managing director, Mr. Leo van Heyningen, started importing Dutch salad vegetables through Hull. To do so at that time he made use of existing liner services between Amsterdam, Rotterdam and Hull and hired road vehicles for the final delivery in the UK.

In 1959 the move was made to Great Yarmouth. Hull had tended to make their distribution pattern too northbound. Moreover, because of the fast growth in business, the firm considered it needed more direct control, of port activities. After a survey of alternative ports, Mr. Walford said it considered Great Yarmouth had the necessary facilities, including, of course, proximity to the firm's Continental activities and, accordingly, took out leases of wharves.

Further developments followed and now, in addition to headquarters in Great Yarmouth, there is a main distribution depot at Offord, near Huntingdon, and 11 branches—at London, Southampton, Bristol, Birmingham, Nottingham, Sheffield, Manchester, Liverpool, Hull, Glasgow and Leith. Superior International now operates four ships of about 400/500 tons.

As it subsequently had a bearing on road transport operation, Mr. Walford said that a larger ship might well be shown to be more economic—on paper—solely on the basis of the quantity of freight moved. But the first requirement with a cargo of perishable produce was that the whole of it could be discharged in a matter of hours and immediately sent on its way.

This was why he was so anxious to have direct control of port activities—which the firm did at the two relatively small ports of Great Yarmouth and Scheveningen. An associated advantage was the absence of road traffic problems now universal around large dock areas.

Indicative of the time-cycle, Mr. Walford explained, was that tomatoes picked in Holland on a Monday morning would be

auctioned and then loaded into their vessel at the Dutch port the same afternoon. After a 10-hour sea crossing the cargo would be discharged at Great Yarmouth on Tuesday morning in about three hours. Unloadingproceeded at the rate of about 10,000 trays an hour straight on to the road vehicles for delivery to the firm's main distribution depot near Huntingdon.

Concurrent with operations on the Tuesday morning, sales of produce are being negotiated with wholesalers and other customers such as multiple stores. Also by the time lorries from Great Yarmouth reach Huntingdon, produce has already been delivered there from other ports or from home growing areas.

Loading for the final delivery commences at Huntingdon from about 2 p.m. onwards and deliveries are completed by 8 a.m. the following morning to all the principal markets in England. In some smaller towns deliveries are made direct to wholesalers while in recent years an increasing proportion of deliveries is being made to supermarkets and multiple stores.

In an age when the economics of scale, and the large but impersonal organizations too often associated with such policy, are taken for granted, Mr. Walford stressed a relevant point here in connection with the unloading at Great Yarmouth. While this is a particular instance it has relevance to ancillary transport operation generally when the standard of service provided seems likely to come a poor second—if that—to the claimed benefits of large-scale operation which seemingly at present so preoccupies politicians and officials evolving national transport policy.

Mr. Watford told me that up to 18 months ago the same group of dock workers specialized in the unloading of his traffic at Great Yarmouth. They took a special interest in their work and Superior International, although they were not employed by the firm.

Now that a rotation system has been enforced the dockers are changed every week—the special relationship between dockers and the company for whom they happen to be working during a particular week is no longer the same. The vital need for all concerned in the distribution of perishable produce to take a personal interest in their work obviously applies to the driver of the C-licensed vehicles completing the final link in the chain. A peculiarity of this trade is that a large proportion of deliveries are made without signature, but discrepancies are rare, a state of affairs which could hardly be expected if drivers and vehicles were hired on a random basis.

The present fleet of road vehicles operated by Superior International numbers 40, all Commers. There are seven 6-tonners, 24 8-tonners and nine 14-ton attics.

The purchase and operation of the 6-tonners has been a recent development. All the vehicles have platform bodies and for their trade an ideal platform length is around 18/20 feet, So permitting an economic load without stacking too high and therefore risking damage to the produce.

Satisfactory experiment

A recent experiment proving satisfactory is the fitting of a fibre-glass body to a 6-tonner by Charrold Ltd., St. Ives. The cross-members are part of the body which gains its strength from being cast as one piece. On an 18 ft. body there has been a saving of 10 cwt. in unladen weight.

During the six months the vehicle had been operated it had been found it was easy to keep clean and was more resistant to minor impacts and damage, coupled with the fact that it was self-coloured. The body had been tested at MIRA and was proving satisfactory in service.

Like many C-licensed operators the firm pursues a policy of one 'driver to one vehicle, with six drivers based at Great Yarmouth, 34 at Huntingdon and an additional one based out at Exeter. But because of the emphasis throughout the whole distribution exercise of cutting overall time of movement to a minimum, Superior International also employ 25 shunters and loaders.

Regarding maintenance, a fitting staff of eight is divided between Great Yarmouth and Huntingdon and it is the company's policy to service vehicles strictly on the 4,000 miles cycle as recommended by the manufacturers.

Mr. Walford added that it was now changing its pattern of servicing with the fitting of the Mecafluid system of automatic chassis lubrication. Some critics of this form of lubrication claim that with traditional methods of lubrication—by a man with a grease-gun—some "inspection" of the vehicle took place simul: taneously. But Mr. Walford contends that the maintenance staff is able now to devote more time directly to inspection because of the time saved.

In addition to the saving of fitters' time this system of chassis lubrication was proving very economical in operation and cut Out wear on shackle pins, while not suffering from the disadvantage of being dependent on a speedometer cable.

In line with this policy the firm also was studying the possibility of dispensing with the traditional method of frequent services by the use of long-life oil and devoting still more time to inspection. Such a policy was consistent with the increasing stringent demands on vehicle fitness now being made by the Ministry of Transport.

Equally important along With vehicle fitness was driver fitness which included reduction, if not elimination, of fatigue. Mr. Walford told me that Bostrorn Viking seats proved very popular with drivers. Because commercial vehicle drivers spent more time at the wheel than many other drivers, more attention, he considered, should be given to equipment that promoted alertness while driving.

As with most C licence operators, except the very largest fleets, there is some inter-working of administrative staff as between the parent business and the transport department. But those employed entirely on transport operation, in addition to Mr. Walford, include two traffic managers, one specializing in fruit and the other in general cargo at Great Yarmouth. To assist in economic operation of the company's vessels, general cargo was also carried to balance out the flow of traffic to and from the Continent. For delivery in the UK hired haulage operating on A and B licence is employed. At Huntingdon there is a depot manager and two traffic managers assisted by three clerks.

Regarding hired transport, all movements are credited forthwith by Superior International for that day's haulage. In effect, the confirmation note as to the movement is a credit note showing the amount due to the haulier. Not only does this ensure prompt payment to the haulier but it is of substantial advantage, Mr. Walford explained. Many small hauliers had inadequate recording and accounting systems and it was both impracticable and inefficient for a company such as Superior International to keep its books open awaiting the belated invoices of several hauliers.

Valuable assistance By the system his company operates all concerned are kept currently appraised as to the cost of their transport, whether on their own or hired vehicles. In this respect Mr. Walford emphasized that they had valuable assistance from the secretarial department of the company in providing all the relevant facts and figures appertaining to transport accounting. On fruit movement alone over £100,000 was expected to be paid out this year to hauliers. Indicative of the total annual movement, several million packages a year were distributed—Dutch tomatoes, cucumbers, lettuce, etc.

Hired haulage was paid for on a full-load basis, consistent with efficient delivery. In theory, a Contract A licence operator had the reassurance of a written contract. But if there was a reduction in trade or seasonal fluctuation beyond the control of his customer the written agreement was of little value to the haulier.

In contrast, where a haulier with a B licence was employed there was a moral rather than a legal mutual interest. If the haulier gave good service it was in the interest of Superior International to keep him as fully employed as possible in the knowledge that he had special interest and experience in the appropriate type of traffic.

Mr. Walford said that in this connection he had knowledge of other importers entering into Contract A agreement with hauliers almost ,"willy-nilly” without thought or regard as to what happened when trade dropped. And he had been approached by a few such hauliers with a view to finding them work.

Elaborating on the main distribution centre at Offord, near Huntingdon, Mr. Walford said that this was on the site of a demolished railway station and as such well-connected to the adjoining main Eastern Region line of British Railways to the north. The area of the site is 7 acres and the main warehouse area measures 54,000 sq. ft., including canopied areas.

The warehouse measures 400 ft. long by 90 ft. wide and there are loading bays on both sides running the full length. Bulk traffic is delivered on one side, including any railborne traffic via the private siding.

The outward-loading bay for vehicles making the final deliveries is fitted with sliding shutter doors throughout the entire length, supplied by P. C. Henderson Ltd., Romford. The bay is provided with a 25 ft. canopy.

With so many problems arising daily from the market fluctuations in the sale of perishable produce, the control system for the loading and route scheduling of vehicles is a key factor in economic operation.

Following completion of sales each day through the regional sales offices of Superior International, the transport office at Huntingdon is handed a consignment note (in quadruplicate) for each delivery to be made.

Each vehicle is allocated an alloy metal board (about foolscap size) with pegs running from top to bottom on the left side. Corresponding perforations in the consignment notes allow for their arrangement in final delivery order with the successive addresses visible to the loading staff. One copy is sent to Great Yarmouth from which the customer's invoice is made out, another is kept at Huntingdon and two are taken by the driver. One he leaves with the goods delivered while the other is signed by the customer. Because of the early hour at which many deliveries are made some of these consignment notes carry precise instructions. According to the distance involved, orders can be accepted up to 4 p.m. for delivery early the following morning. Mr. Walford told me that a system of tape-recording of sales over the telephone is being installed so as to provide both increased accuracy and a saving in time.

As to the loadability of the traffic, Mr. Walford said he preferred to load to a height of 3+--5 ft., according to the size of the vehicle, as too high a load results in crushing the lower cartons in which modern fruit and vegetables were packed.

In winter one had to guard against frost damage by the use of a good-quality sheet. In this connection a good cardboard carton was adequate to keep out all but the most severe frost and to that extent was an improvement on the former wooden box. But the biggest enemy was rain and this was one of the reasons for changing over from the 8-tonner to the 6-tonner for the final delivery.

Elaborating on this point, Mr. Walford explained that as the 8-ton load normally meant a longer delivery round, and therefore an earlier start, there were more LOP (left on premises) deliveries than otherwise. On wet mornings this could be damaging to the consignment even before the customer actually handled it. It is a peculiarity of the trade that many such deliveries are left without signature.

In line with developments in other agricultural markets several of the fruit and vegetable markets to which they now deliver were new and efficient. Often on the outskirts of town, they were therefore more accessible. But the problem marketstraffic-wise—such as Covent Garden, unfortunately still remained and added to distribution costs.

Superior International's transport costing system was based on mileage coupled to a packing "unit". Such a unit was necessary in the interest of simplicity because it dealt with millions of packages which could be in a variety of forms such as cardboard cartons, trays, wooden boxes and bags with individual weights ranging from 6 lb. to + cwt.

Using such a unit load, the company's C licence operation was costed on a national average with analysis of loads to areas. Here again Mr. Walford stressed that the firm had considerable support from the company's basic statistics.

Company expansion still continued and Mr. Walford told me of future plans he had in mind to enable the transport departments to keep abreast of such developments. At the time of my visit the economics of roll-on, roll-off operation were being studied. In fact, while I was writing this article Superior International committed itself to commencing a roll-on /roll-off service in about 15 months' time by the placing of an order for a vessel to be in service by late 1968.

Allied to determination to improve still further the mechanical standard of the fleet of road vehicles, the firm will have in use later this year a new garage at Huntingdon measuring 180 ft. X 40 ft., together with stores and office premises. It would include a six-vehicle service workshop with both a pit and lifts, tyre bay, paint spraying bay and washing bay with a full-time garage manager, already appointed, having maintenance as his prime function.

In the next two years they were planning to open three satellite distribution depots in the South West, North West and Yorkshire, the actual sites of which are still to be finalized. Significantly the proposals—if implemented—announced by the Minister of Transport as to drivers' hours the same week as I visited Great Yarmouth, would have an important bearing, Mr. Walford told me, on the siting of these depots. Similarly the effect of motorway extension not yet completed has to be taken into account so as to optimize maximum loading on trunk vehicles coupled with a final delivery radius that facilitates the provision of a service that meets the requirements of customers.

Ultimately the Huntingdon depot would be the supply point for English and imported produce, other than Dutch, with the capacity of the satellite depots providing for up to 20 loads a night.

Regarding palletization, there were at present too many problems in the customers' hands to be resolved before Superior International could make the final delivery on pallets. But palletization was already employed in Holland for bulk movement and in the UK it was intended to employ fork lift truck, roller conveyers and other mechanical aids at the new depots where it could be shown advantageous to do so.

Throughout my interview with Mr. Walford there were the inevitable intervening telephone calls from a variety of sources common to most transport operation—terminal points, drivers, and delivery points—in all of which the time factor was obviously of crucial importance. But because of the overall size of the operation—not too big as to lose individual personality but large enough to have resources to provide and maintain an adequate fleet—it was possible for all concerned to have the advantage of being able to see the contribution their efforts made to the distribution exercise as a whole to the benefit of both employer and employee alike.