Module-based aluminium bodies..

Page 111

If you've noticed an error in this article please click here to report it so we can fix it.

ANEW system of aluminium bodywork construction, based on a 4 ft. module, was announced on Wednesday by Unit Body Developments Ltd., Elstree Road, Elstree, Boreham Wood, Herts., which will enable a network of distributors to assemble the bodies on their premises, the distributors being experienced body builders in every case. UBD staff will be available for technical liaison with customers and potential users and arrangements have been made to show a colour film (with commentary) to potential users in many parts of the country. For export, the jig-built components can be shipped in knock-down form for assembly by local labour.

Supplied by RTZ Metals Ltd. to UBD design, the extruded aluminium sections are of BSHE3OWP specification, while the sheet is of NS3 half-hard aluminium if required for normal cladding and of NS4 halfhard material for applications involving stressed sheet.

Typifying the forms of construction employed, a demonstration body is of the plain box type, with roller shutters on the front nearside and at the back, which has a length of 16 ft, a width of 7 ft 6 in, and an internal height of 8 ft 3 in. An optional feature is a skirt extension. Other options include a

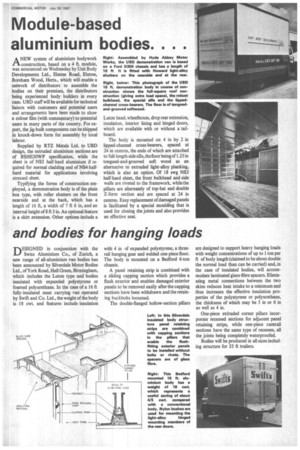

Right: Assembled by Hyde Abbey Motor Works, the UBD demonstration van is based on a Ford D300 chassis and has a length of 16 ft It is fitted with Howard light-alloy shutters on the nearside and at the rear.

Right, below: This photograph of the UBD 16 ft. demonstration body in course of construction shows the full-square roof construction igiving extra load space), the robust bulkhead, the special sills and the lippedchannel cross-bearers. The floor is of tonguedand-grooved softwood.

Luton head, wheelboxes, drop rear extension, insulation, interior lining and hinged doors, which are available with or without a tailboard.

The body is mounted on 4 in by 2 in lipped-channel cross-bearers, spaced at 24 in centres, the ends of which are attached to full-length side sills, the floor being of 1.25 in tongued-and-grooved soft wood as an alternative to extruded light-alloy planking, which is also an option. Of 18 swg NS3 half-hard sheet, the front bulkhead and side walls are riveted to the framework, while the pillars are alternately of top-hat and double Z-form section and are spaced at 24 in centres. Easy replacement of damaged panels is facilitated by a special moulding that is used for closing the joints and also provides an effective seat.